Trample-deformation-resistant adjusting device for shallow-buried gas pipe

A technology for gas pipelines and adjustment devices, which is applied to pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve problems such as increased pipeline costs, inapplicability, and difficulty in meeting production needs, so as to avoid surface movement and deformation damage, solve the effect of resource recovery and pipeline safety, and ease of construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

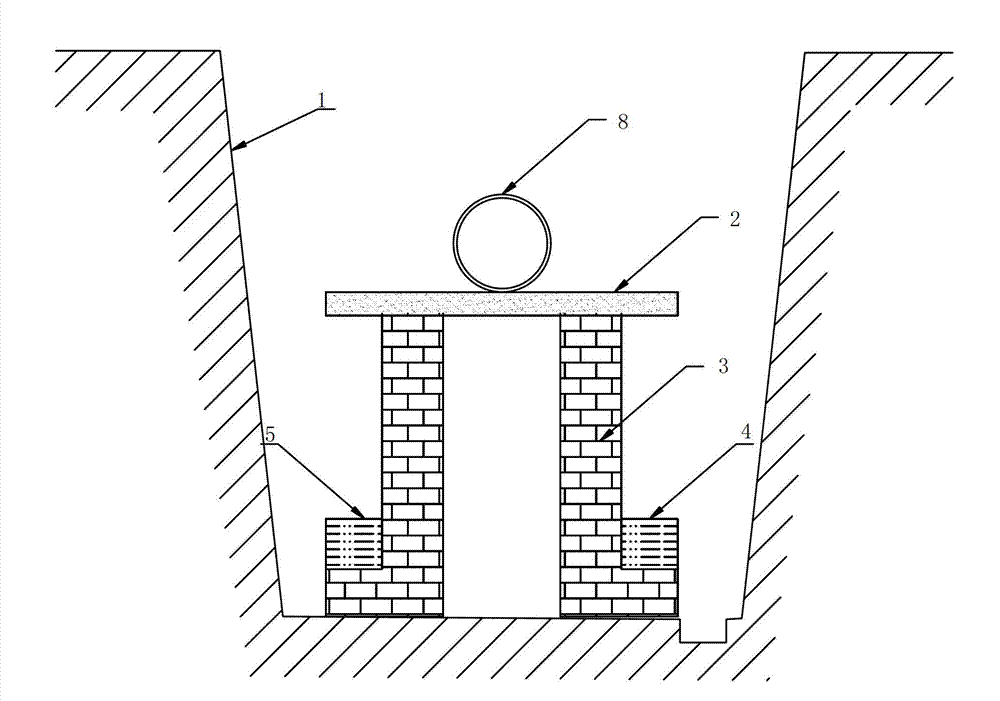

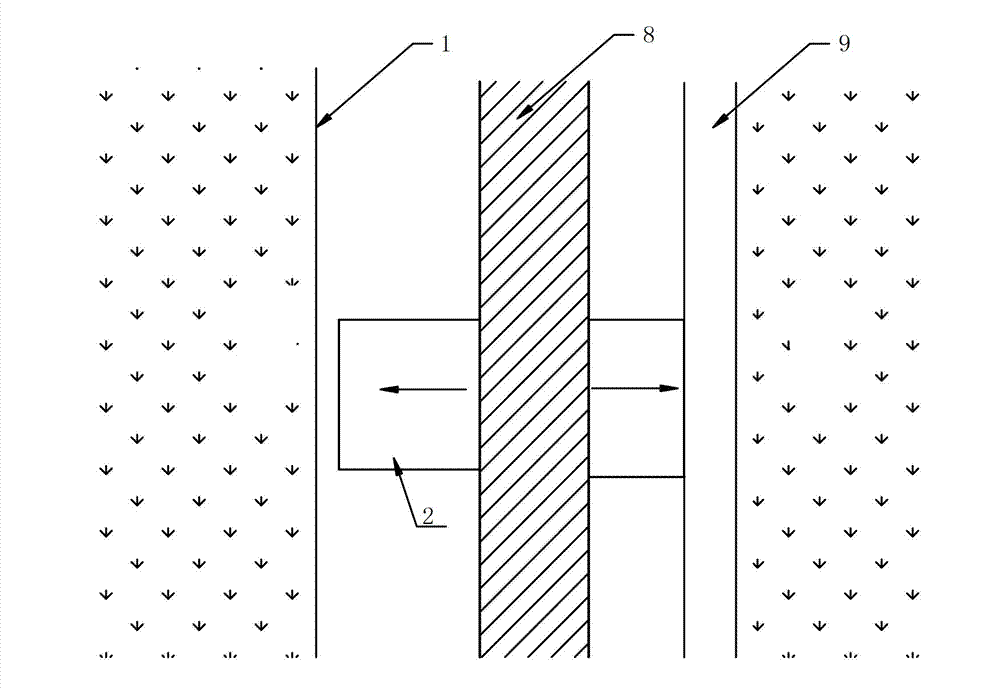

[0021] Such as figure 1 and figure 2 As shown, this embodiment is an anti-mining deformation adjustment device for shallow buried gas pipelines, which includes an excavated pipe trench 1, a smooth backing plate 2 for supporting the pipeline, and an adjustable base for supporting the smooth backing plate 2. Seat 3, the smooth backing plate 2 is placed on the top of the adjustable base 3, the smooth backing plate 2 and the adjustable base 3 are both located in the excavated pipe trench 1, and the smooth backing plate 2 and the adjustable base 3 form a support support for the pipe. Excavating the pipe trench 1 refers to digging out the covering layer of the pipe, and forming a certain excavation space, which facilitates free relative movement between the pipe and its support.

[0022] In this embodiment, the smooth backing plate 2 is a wooden backing plate, a porcelain backing plate or a rectangular plate made of other materials with a smooth upper surface, and the pipeline ca...

Embodiment 2

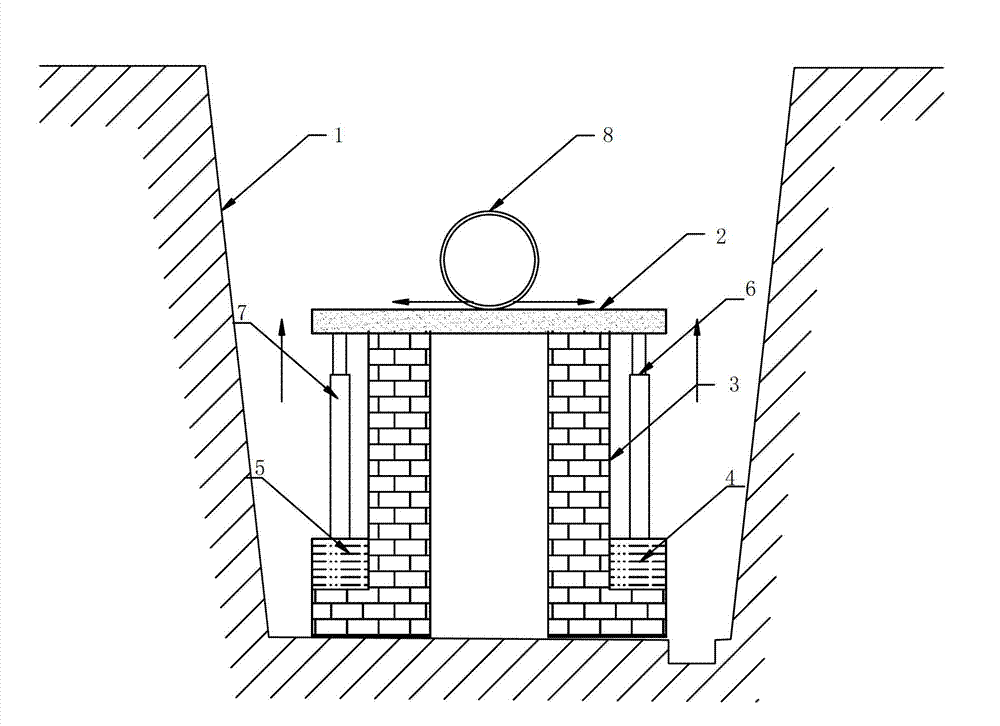

[0024] Such as image 3 As shown, in this embodiment, a shallow-buried gas pipeline anti-mining deformation adjustment device includes excavation pipe trench 1, a smooth backing plate 2 for supporting the pipeline, and an adjustable base for supporting the smooth backing plate 2. Seat 3, the first jack 6 for supporting the smooth backing plate 2 and the second jack 7 for supporting the smooth backing plate 2, the smooth backing plate 2 is placed on the top of the adjustable base 3, the first The first jack 6 and the second jack 7 are located on both sides of the adjustable base 3 respectively, and the smooth backing plate 2, the adjustable base 3, the first jack 6 and the second jack 7 are all located on the Excavate the trench 1. Excavating the pipe trench 1 refers to digging out the covering layer of the pipe, and forming a certain excavation space, which facilitates free relative movement between the pipe and its support. The parameters of the first jack 6 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com