Mixed type steam Rankine combined cycle power generation device

A Rankine cycle, steam technology, applied in steam engine installations, combined combustion mitigation, machines/engines, etc., can solve the problems of no utilization method, low quality of waste heat, and limited versatility of recovery methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

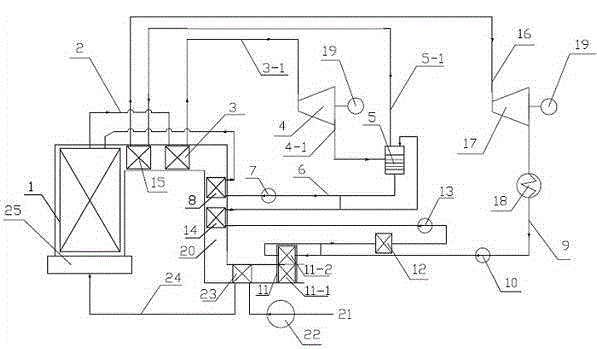

[0032] Such as figure 1 As shown, a hybrid steam Rankine combined cycle power generation device, the device includes a high-pressure end steam Rankine cycle, a low-pressure end steam Rankine cycle, the high-pressure end steam Rankine cycle:

[0033] The steam Rankine cycle at the high-pressure end refers to the saturated steam 2 coming out of the boiler body 1, which forms the high-pressure superheated steam 3-1 through the high-pressure superheater 3, and sends it to the high-pressure steam turbine 4 to drive the generator 19 to generate electricity; the high-pressure steam turbine 4 comes out The exhausted steam 4-1 is directly mixed with the feedwater of the low-pressure steam Rankine cycle in the low-pressure steam generator 5 to generate saturated steam 5-1, and the formed condensed water 6 is sent to the high-pressure feedwater heater 8 and the boiler through the high-pressure feedwater pump 7 Boiler body 1 and boiler body 1 generate saturated steam again, thus forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com