Composite drill bit with cutter blade provided with cutter disk cutting structure

A technology of cutting structure and compound drill bit, which is applied in the direction of drill bit, drilling equipment, earthwork drilling, etc., can solve the problems of increasing the working load of PDC teeth, large space of drill bit, and accelerated wear speed, so as to improve the performance and life of the drill bit and save the drill bit The effect of shrinking space and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

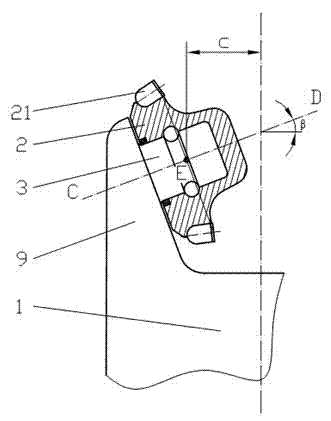

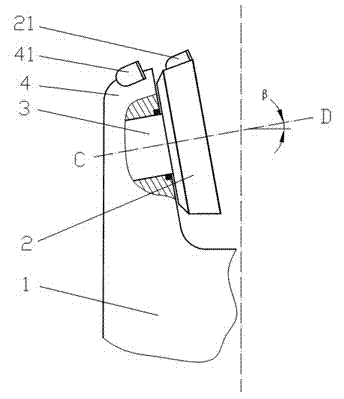

[0086] Such as image 3 , 4 , shown in 5, 6, and 7: a compound drill bit with a disc cutter cutting structure on the blade, including a drill body 1, a fixed blade 4, and a disc cutter 2, the drill body 1 is provided with a fixed blade 4, and the fixed blade Fixed cutting teeth 41 are arranged on the wing 4, the range of the offset angle α of the disc cutter 2 is 20°≤|α|≤90°, and at least one disc cutter 2 and the disc cutter cutting tooth 21 on the drill body 1 And the disk cutter cutting unit constituted by the disk cutter shaft 3, at least one disk cutter cutting unit is arranged on the fixed blade 4, and the disk cutter 2 and the fixed blade 4 form a rotational connection. The fixed blade 4 is provided with disc cutter grooves, and the disc cutter cutting unit is arranged in the disc cutter groove. Both ends or one end of the disc cutter shaft 3 are connected to the fixed blade 4, and the disc cutter 2 is connected to the fixed blade through the disc cutter shaft 3. 4 to ...

Embodiment 2

[0088] This embodiment is basically the same as Embodiment 1, the difference being that: the drill bit body 1 is also provided with an independent fixed cutting structure consisting of an independent fixed blade 4 and its fixed cutting teeth 41 . Such as Figure 12 , 20 As shown, two rows of fixed cutting teeth 41 are arranged on the fixed blade 4 provided with the disc cutter cutting unit. On the basis of the disc cutter cutting unit, the drill body 1 is also provided with a fixed cutting structure independent of the disc cutter cutting unit. 4. The added fixed cutting structure 4 has increased the arrangement of teeth of the drill bit, making the drill bit more suitable for drilling in harder formations.

Embodiment 3

[0090] This embodiment is basically the same as Embodiment 1 or 2, the difference being that there are both positive and negative offset disk cutter cutting units on the drill body 1 . Such as Figure 14 , 15, 16, and 17, the distance between the positive and negative offset disc cutter cutting units is relatively close, and the shaft end of the disc cutter shaft 3 that is closer to the disc cutter 2 can be connected to the same fixed blade 4, so that the drill bit structure is more Compact, when the outer diameter of the drill bit is constant, more disc cutter cutting units and the number of cutting teeth can be set; at the same time, the fixed blades 4 between the disc cutter cutting units and the fixed blades 4 at both ends of the disc cutter cutting unit are Fixed cutting teeth 41 may be provided to form a fixed cutting structure. It can be seen from the figure that this embodiment has a compact structure and a large space for the fixed cutting teeth to arrange the teeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com