High-efficiency and energy-saving starting method for heat flow coke calcination in aluminum electrolysis

A high-efficiency energy-saving, roasting start-up technology, applied in the field of aluminum electrolysis production process, can solve the problems of increased monitoring and maintenance intensity of employees, shortened service life of electrolytic cells, and low labor intensity, so as to improve energy utilization rate, reduce possibility, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

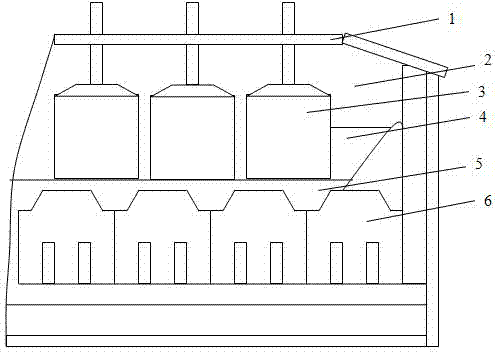

Image

Examples

Embodiment Construction

[0024] 1. Filling of semi-silo material of aluminum electrolytic cell

[0025] In the process of filling the electrolytic cell, the half-bunk electrolyte powder is filled, which not only ensures that there is enough molten electrolyte to fill the cathode cracks, but also protects the cathode from excessive expansion and deformation caused by excessive thermal shock. At the same time, half-bunk filling ensures coke particles The generated heat flow flows in the sealed groove to strengthen the roasting of the side extension legs and the carbon block.

[0026] 2. Start 8 hours after lifting the anode

[0027] After the electrolytic cell was energized and baked for 72 hours, the anode was lifted for 8 hours, and the start-up was performed after 8 hours. Starting up after 8 hours of lifting the anode makes the cathode heating gradient of the electrolytic cell more reasonable, reduces the impact of thermal stress on the cathode, reduces the possibility of early damage to the cathode, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com