Method for separating C5 fraction

A C5 fraction and extractive distillation technology is applied in the fields of azeotropic distillation, reactive distillation, separation of C5 fractions, and extractive rectification to separate and cracked C5 fractions, which can solve the problems of complex process and difficult operation, and achieve The effect of simplified process, high yield and purity, and reduced number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

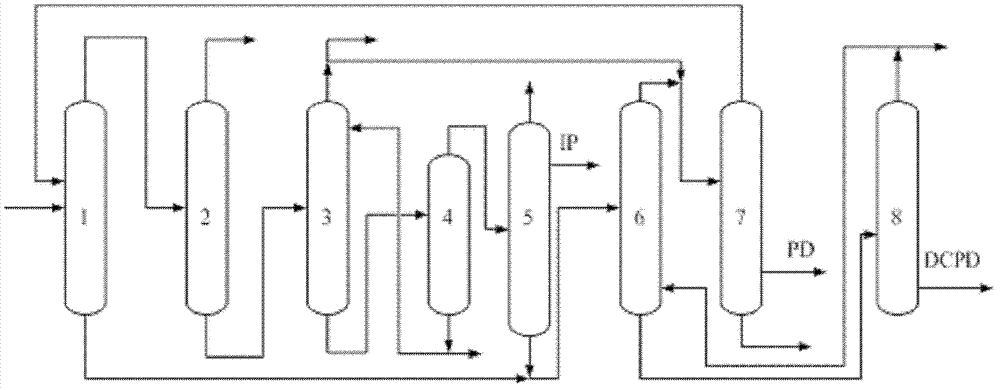

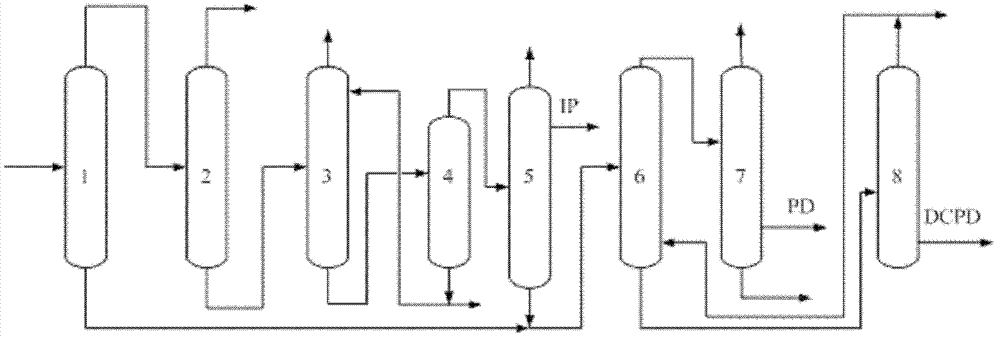

[0050] Such as figure 1 Shown, the method for separating carbon five cuts, comprises the following steps:

[0051] (1) Weight removal: carbon five raw materials (mainly composed of carbon four 8.4%, pentane 11.6%, pentene 19.2, alkyne 0.2%, isoprene 21.4%, cyclopentadiene 17.2%, piperylene 13.9%, carbon six 8.1%) is sent to weight removal tower 1, the number of theoretical plates of weight removal tower is 62, operating pressure 0.3MPa, tower top temperature 68 ℃, tower still temperature 102 ℃, liquid residence time 2.3 hours; Here, Dicyclopentadiene undergoes a dimerization reaction to generate dicyclopentadiene, with a conversion rate of 85%; heavy components such as piperylene and dicyclopentadiene are separated from isoprene, and are extracted from the tower tank and sent to piperylene and In the dicyclopentadiene refining unit, the recovery rate of piperylene and dicyclopentadiene in the bottom of the tower is over 99.5%, and light components such as isoprene are extract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com