Harmless comprehensive treatment method for cyanide-containing tailing pulp

A comprehensive treatment and harmless technology, applied in mining wastewater treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the high cost of standard treatment, unstable environmental protection, and the difficulty of direct treatment of cyanide-containing tailings slurry and other issues to achieve the effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

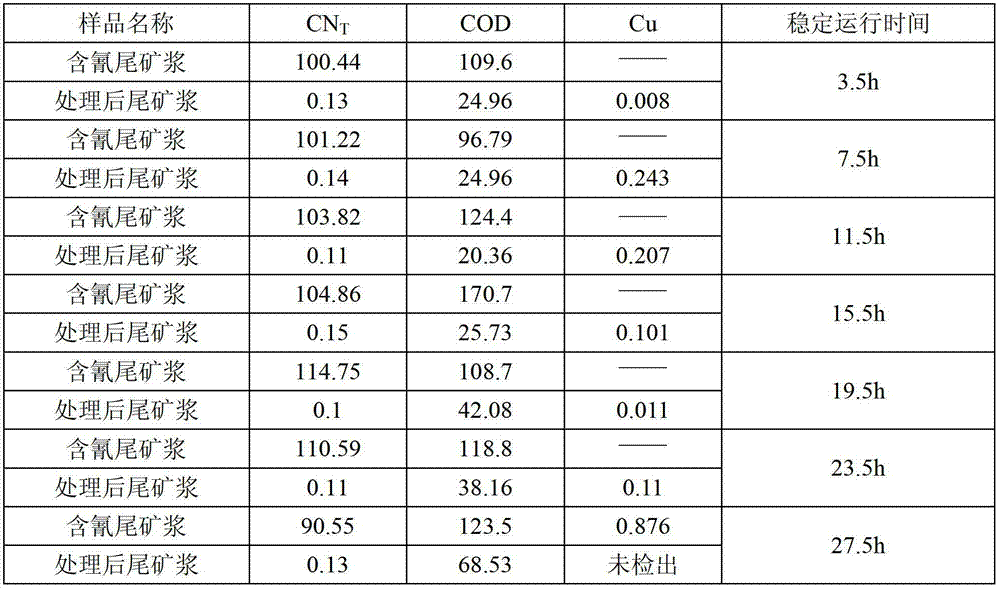

[0080] Using the present invention to carry out the comprehensive treatment expansion test of "slurry concentration + cyanide reduction pretreatment + Inco method oxidation" on the cyanide-containing tailings pulp produced in the actual production process of a gold mine, the processing capacity is 240m 3 / d, see Table 1 for the treatment results of cyanide-containing tailings pulp, and Tables 2, 3 and 4 for the toxic leaching results of cyanide-containing tailings pulp.

[0081] Table 1 Water quality results after treatment of cyanide-containing tailings slurry Unit: mg / L

[0082]

[0083] Table 2 Overturn oscillation method Unit: mg / L

[0084] sample number

Parallel 1

Parallel 2

[0085] Analysis results CN T

0.23

0.29

Leaching toxicity identification standard value CN T

5

5

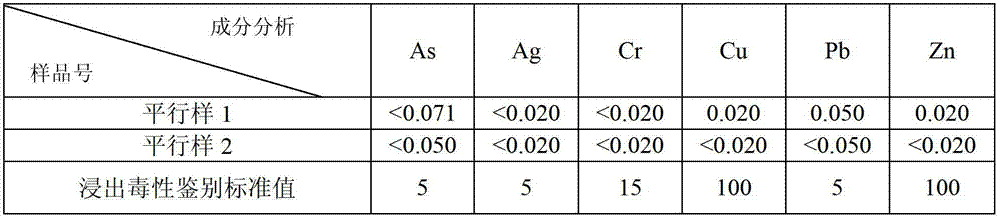

[0086] Table 3 Sulfuric acid nitric acid method Unit: mg / L

[0087]

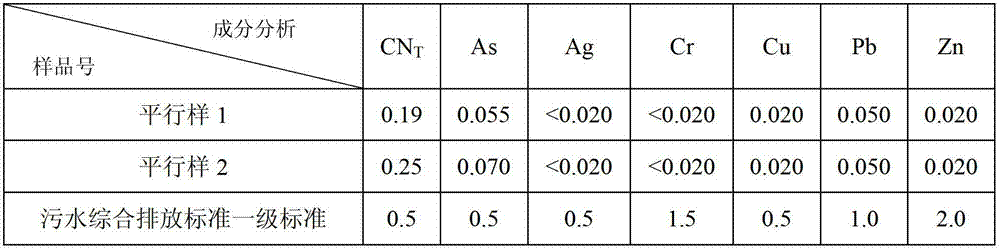

[0088] Table 4 Horizontal shaking method Unit: mg / L

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com