Method for preparing large-area graphene sponge

A graphene sponge, large-area technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as limited instruments, limited templates, and inability to prepare large areas, and achieve high adsorption capacity and cost. Low, achieve the effect of large area preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Ethanol is used as a solvent, and the substrate temperature is 40°C to prepare a graphene sponge

[0017] In the first step, 100 mg of graphite oxide was weighed, poured into a beaker filled with 200 ml of ethanol, and ultrasonicated for 1 hour to obtain a uniform graphene oxide suspension.

[0018] In the second step, the glass substrate is ultrasonically cleaned with alcohol, then ultrasonically cleaned with acetone, and finally ultrasonically cleaned with deionized water, dried and placed on a heating table, and the temperature is heated to 40°C.

[0019] In the third step, the graphene oxide dispersion is poured into the spray gun, and the dispersion is sprayed onto the heated glass substrate by the spray gun.

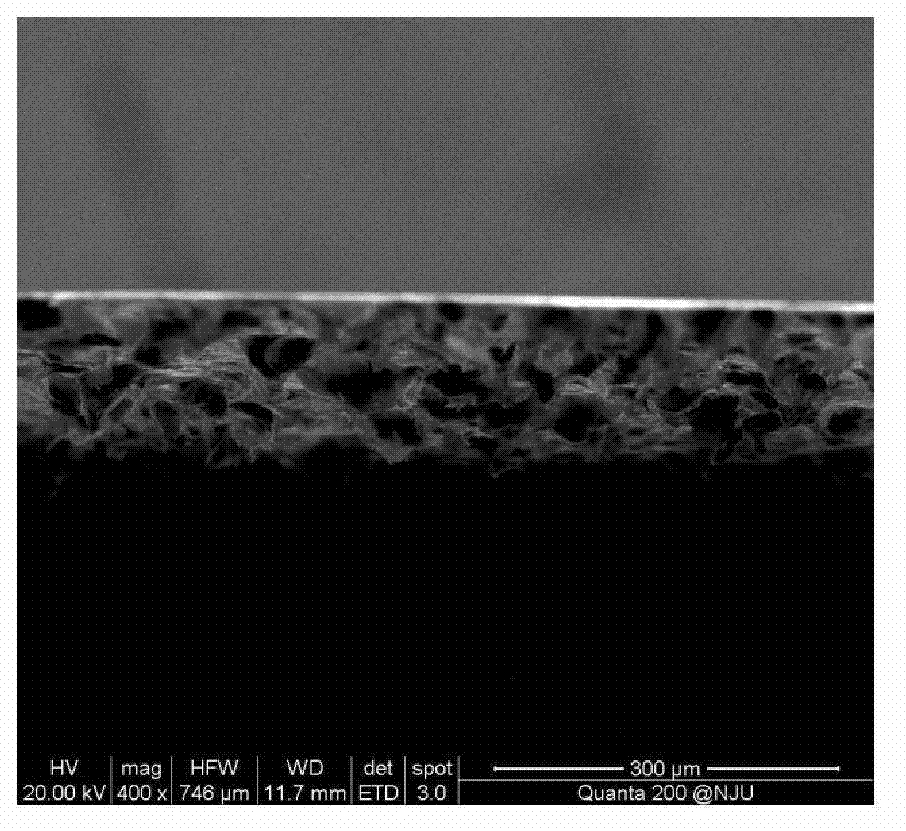

[0020] The fourth step is to put the obtained graphene oxide sponge into a container containing hydrazine hydrate, seal it well, heat it to 95°C, and use hydrazine vapor to reduce it to finally obtain a graphene sponge. figure 1 For the cross-sec...

Embodiment 2

[0021] Embodiment 2: ethanol is solvent, and substrate temperature is 70 ℃

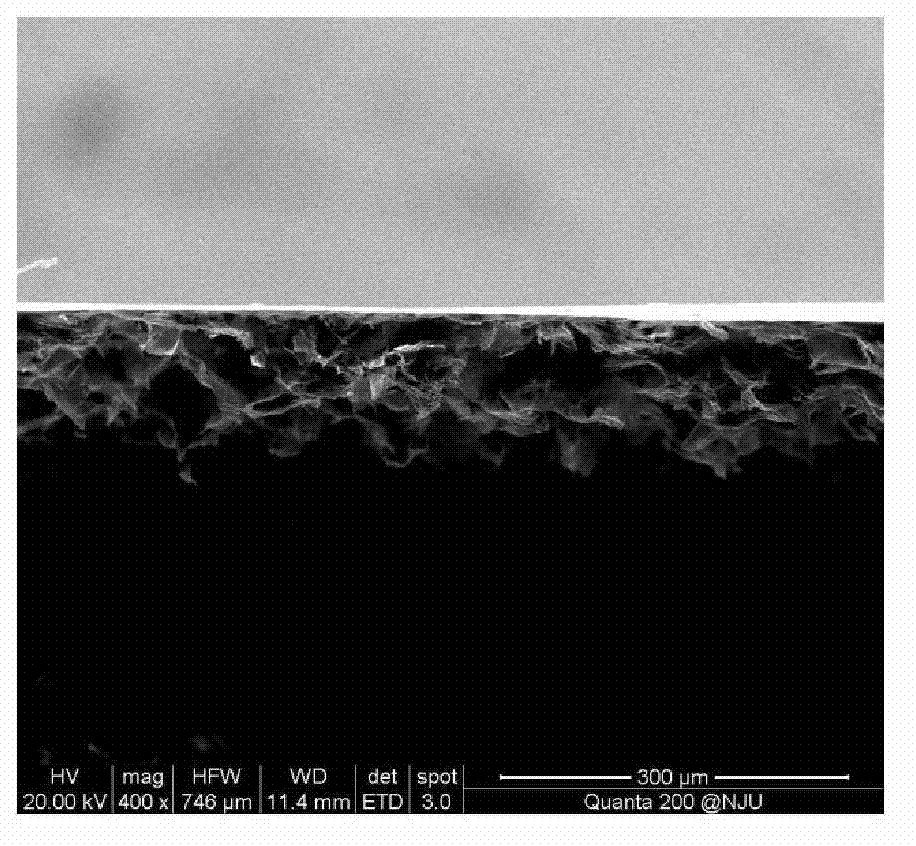

[0022] The preparation method is basically the same as in Example 1, except that the temperature of the substrate is changed from 40°C to 70°C, figure 2 It is a scanning electron microscope picture of the obtained graphene sponge. It can be seen that the sponge is also a porous structure, and the graphene sheet is bent.

Embodiment 3

[0023] Embodiment 3: ethanol is solvent, substrate temperature is 55 ℃

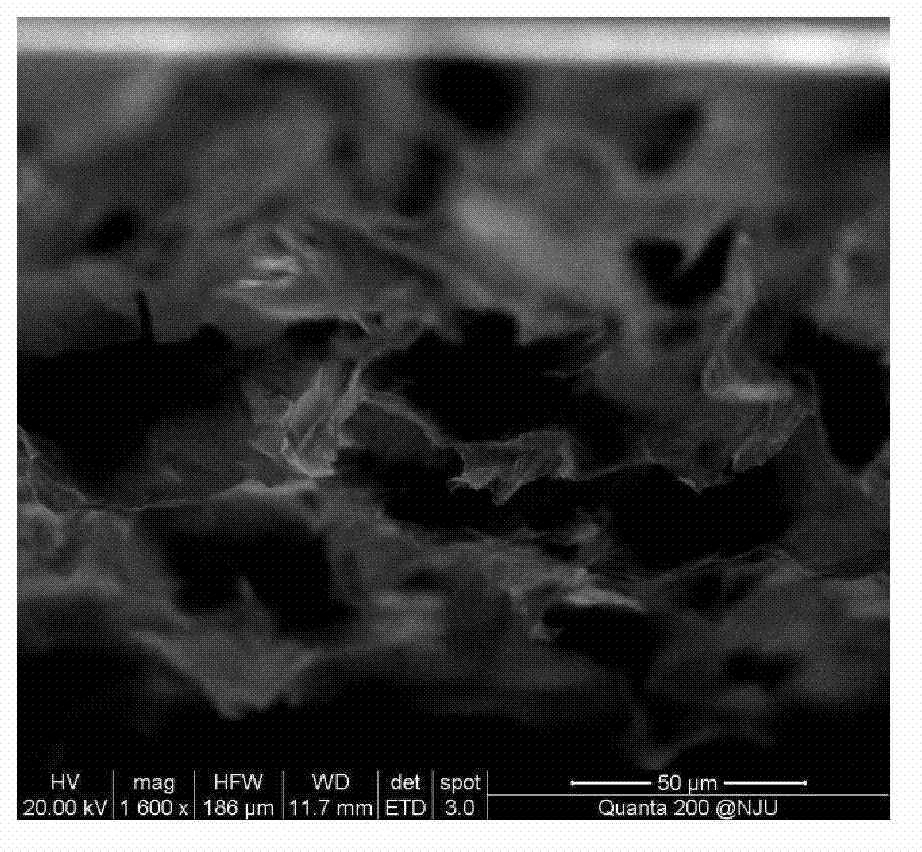

[0024] The preparation method is basically the same as in Example 1, except that the temperature of the substrate is changed from 40°C to 55°C, and the temperature at which the graphene oxide sponge is reduced is 110°C. The obtained sponge structure is as follows: image 3 As shown, it is also a porous structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com