Integrated type side outer plate

A side wall outer panel and integral technology, applied in the field of automobile body parts, can solve problems such as unsatisfactory requirements, affecting accuracy, and difficulty in matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

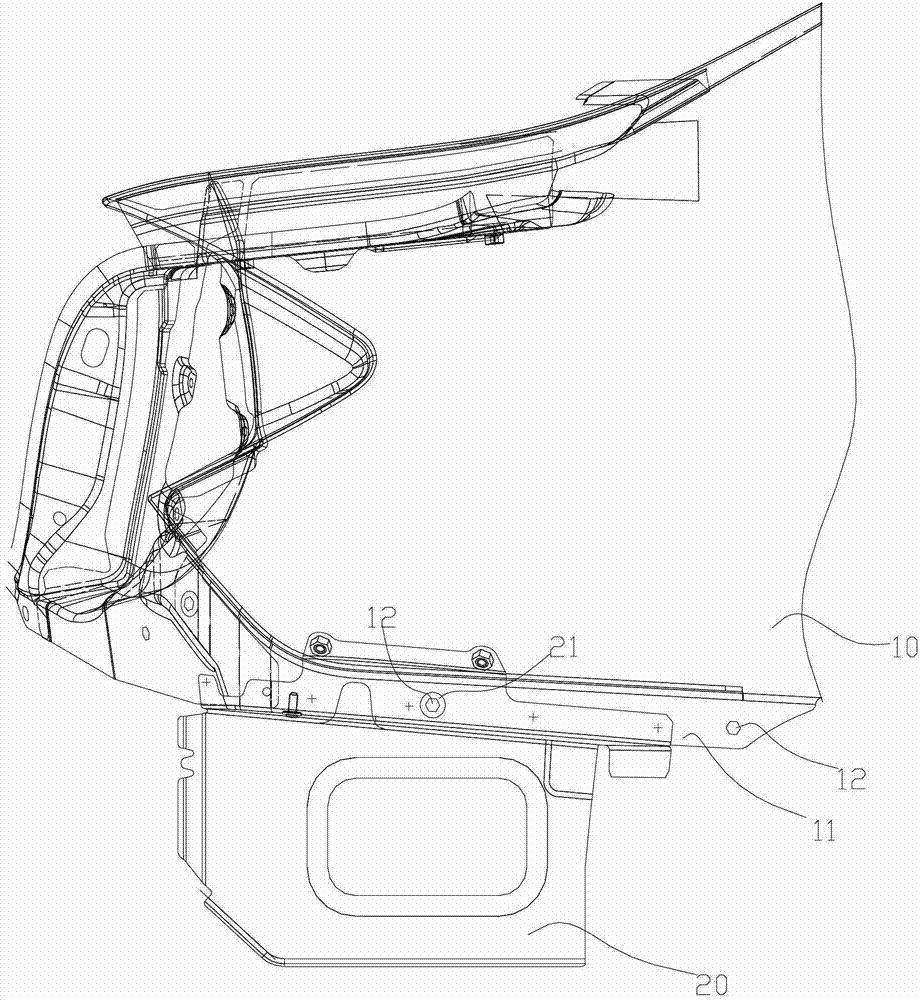

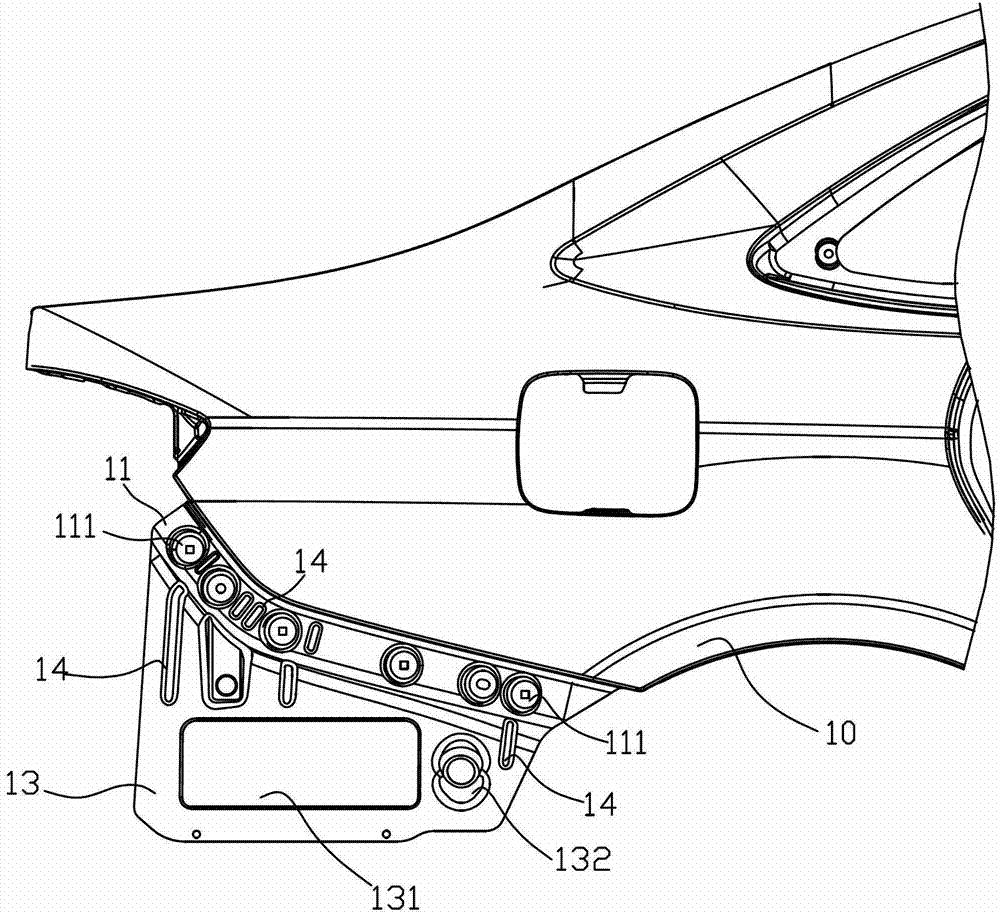

[0008] Such as figure 1 , an integral side wall outer panel, the body of the side wall outer panel 10 at the rear protection installation surface 11 extends toward the bottom of the vehicle to form an installation part 13, and the installation part 13 is provided with a ventilation frame installation hole 131 and There are mounting holes 132 for the water guide pipe at the rear of the sunroof. The rear guard mounting surface 11 is provided with threaded mounting holes 111, and a plurality of threaded mounting holes 111 are evenly spaced along the vehicle length direction.

[0009] The side wall outer panel 10 and the mounting portion 13 are stamped and formed at one time.

[0010] The mounting portion 13 is provided with reinforcing ribs 14 on the side of the ventilation frame mounting hole 131 .

[0011] The ventilation frame installation hole 131 is located in the middle of the installation part 13 , and the skylight rear water pipe installation hole 132 is located beside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com