Cutting fluid aerosol minimal quantity lubrication method and device

A technology of micro-lubrication and cutting fluid, which is applied in the direction of liquid injection device, device for coating liquid on the surface, spraying device, etc. It can solve the problem of not being able to improve the lubricity and cooling of cutting fluid, and not being able to lubricate and cool the cutting process area, etc. problems, achieve the effects of reducing particle pollution, improving surface quality, and enhancing directional adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

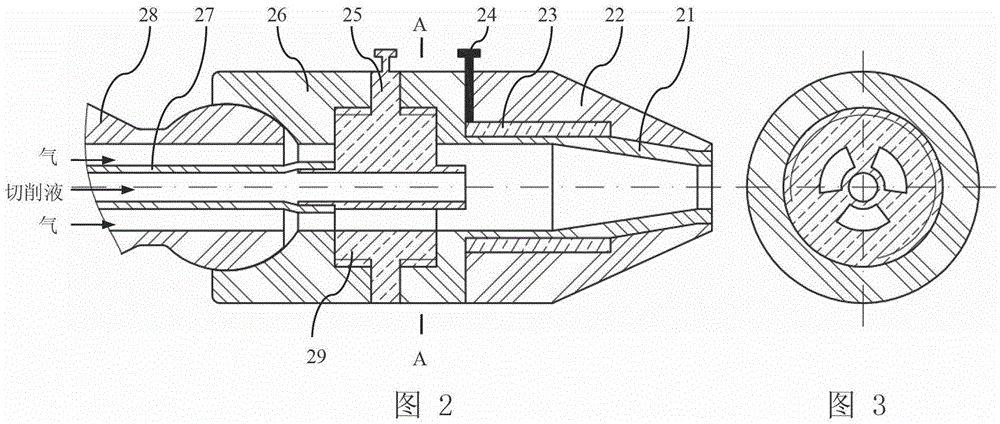

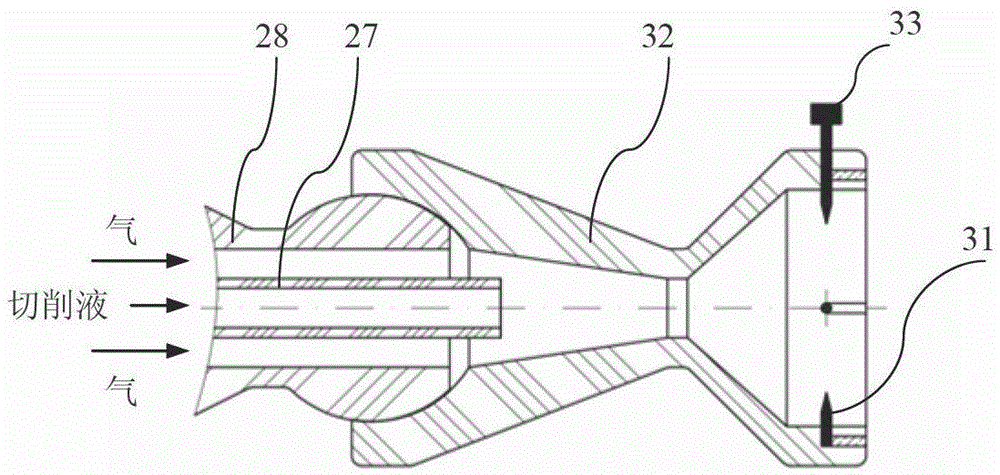

[0037] A cutting fluid aerosol micro-lubrication method. Compressed air and cutting fluid are sent to the nozzle to mix to form a cutting fluid aerosol. The nozzle is equipped with a charging electrode connected to high-voltage static electricity. The charging electrode electrifies the cutting fluid aerosol, and the charged cutting fluid aerosol Spray to the machining area for lubrication and cooling. The charging electrode electrifies the cutting fluid mist through electrostatic induction, corona discharge or contact discharge. The electrical conductivity of the cutting fluid is not less than 10 -9 S / m. The voltage of the charging electrode is plus or minus 1 kV to plus or minus 100 kV, and the current is not more than 2 mA. The pressure of the compressed air is 0.1MPa-1.2Mpa. The flow rate of the cutting fluid is 1mL / h to 1000mL / h. The distance from the nozzle to the cutting area is 10mm-400mm.

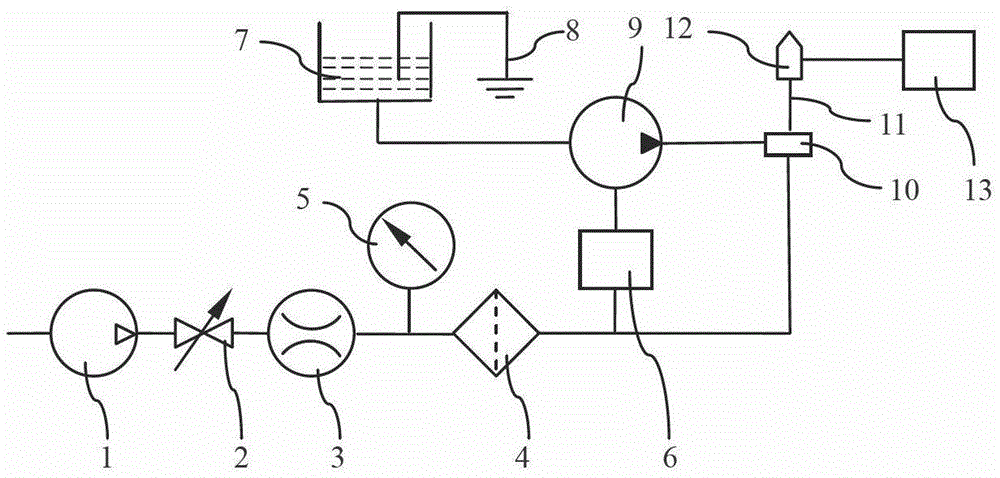

[0038] Such as figure 1 The shown cutting fluid mist micro-lubrication de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com