Numerical control equipment processing tool and operating methods thereof

A technology of numerical control equipment and working methods, which is applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor coaxiality, low efficiency, long working hours, etc., so as to improve the processing quality and increase the degree of versatility , The effect of high workpiece consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

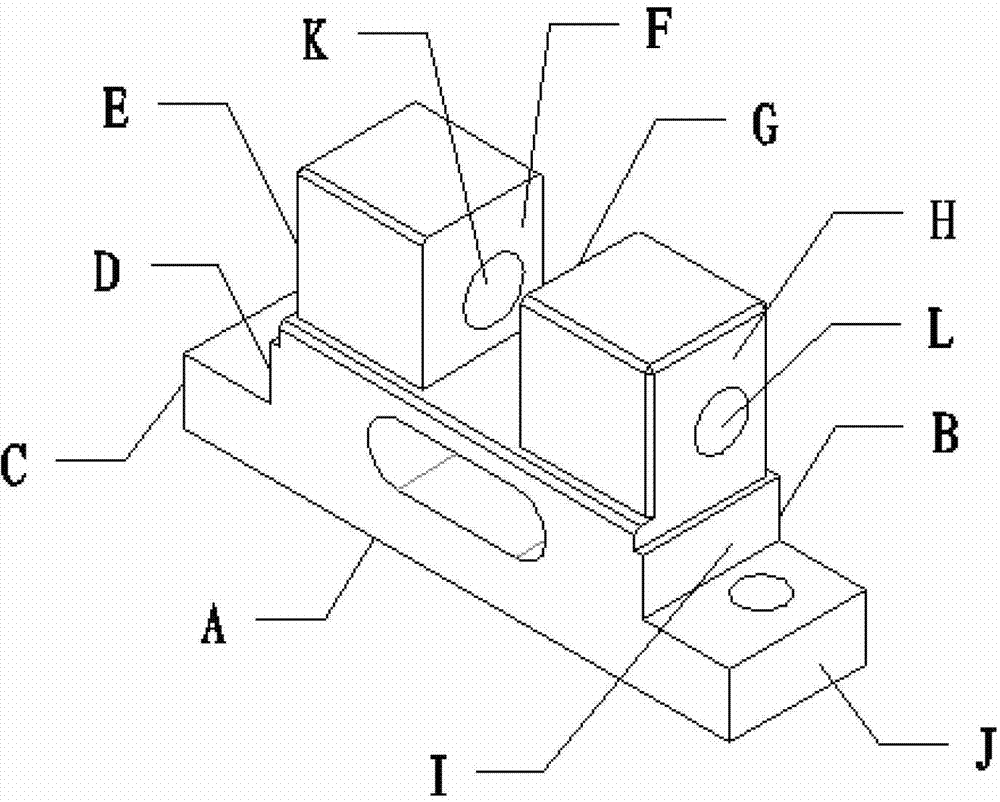

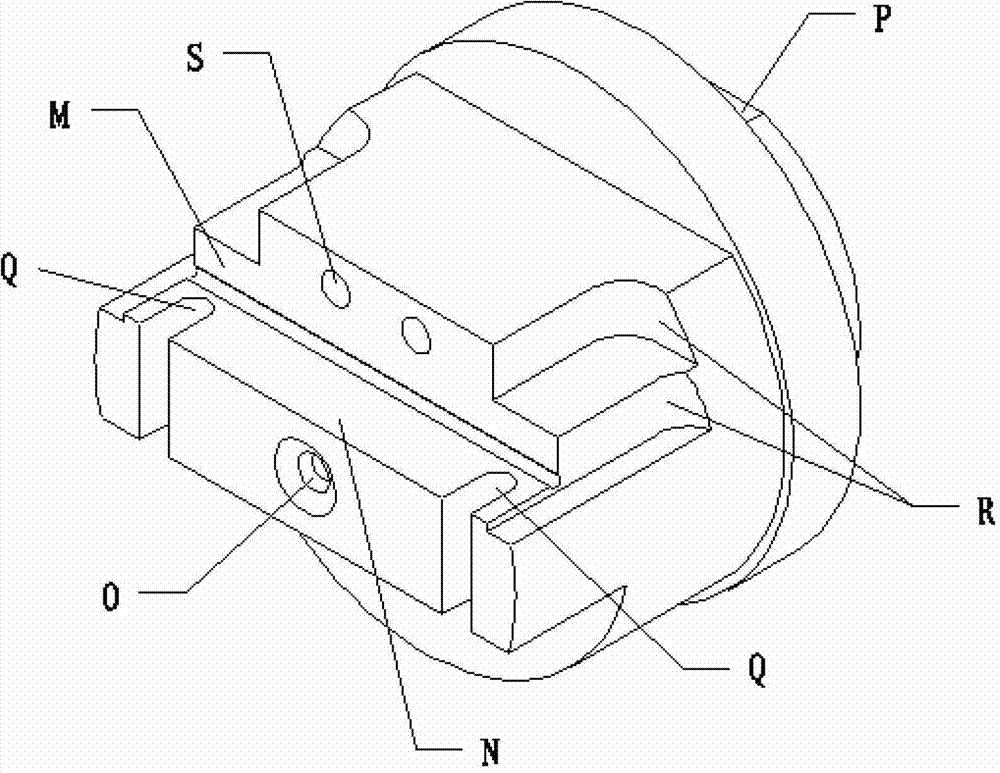

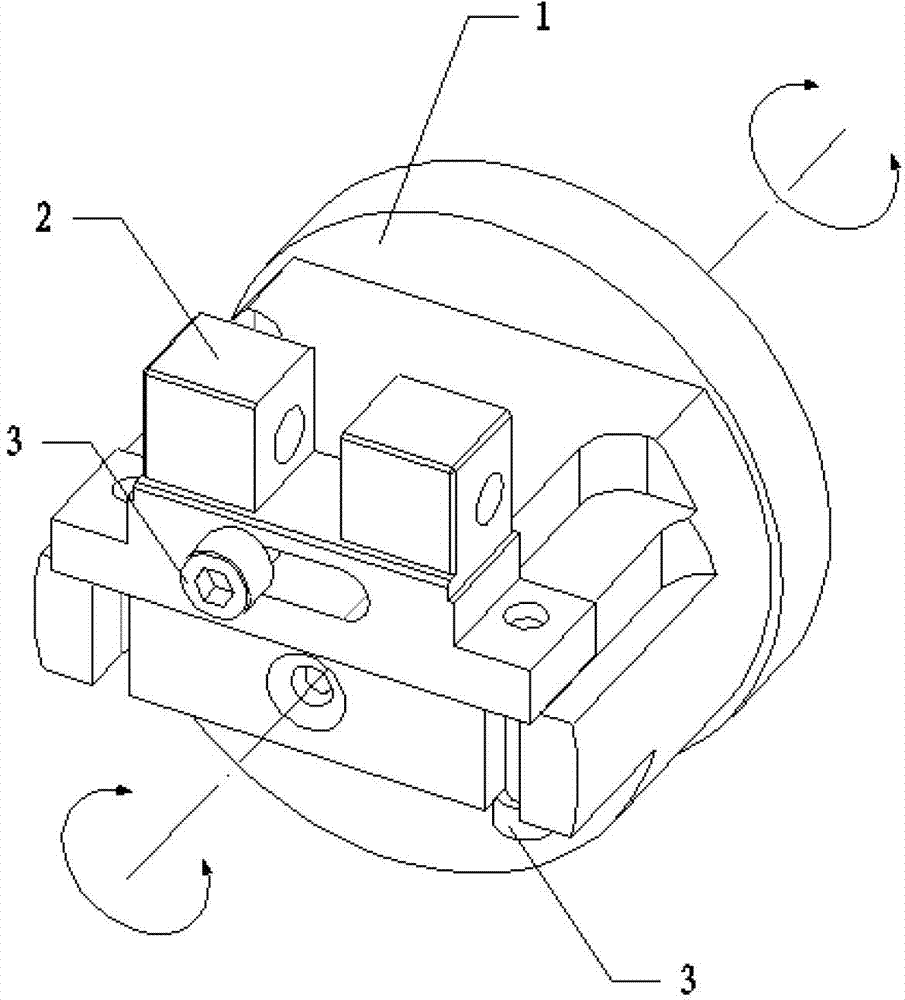

[0022] Embodiment: a kind of numerical control equipment processing tooling, it is characterized in that this tooling 1 is a cylindrical workpiece, there is a central hole O in the center of the front, and there are three clamping planes P evenly distributed on the outer edge of the rear end of the tooling 1; 1 There are rear positioning surface M and lower positioning surface N for positioning the rear plane B of the workpiece 2 and the lower plane A, the rear positioning surface M has a threaded positioning hole S, and the lower positioning surface N has a positioning hole Q corresponding to the workpiece 2 ; Tooling 1 has an undercut R. (See Figure 1-Figure 3 )

[0023] There are two threaded positioning holes S on the rear positioning surface M. (See figure 2 )

[0024] There are two holes Q corresponding to the workpiece 2 on the lower positioning surface N. (See figure 2 )

[0025] The hole Q is a via hole.

[0026] The number of the undercuts R is 4 according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com