Process controlling method in production of N80-1 non-quenching seamless oil sleeve

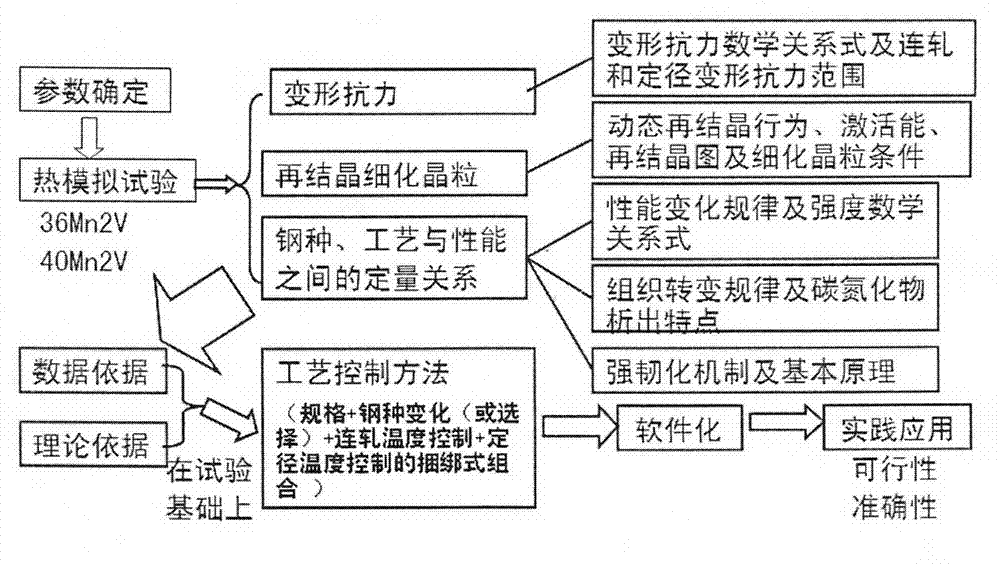

A process control, non-quenching and tempering technology, which is applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem of losing operability and practical significance, deformation amount, deformation temperature, deformation rate, and cooling rate parameters. Control, lack of tensile properties and impact properties and other issues, to achieve the effect of saving heat treatment resources, shortening lead time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

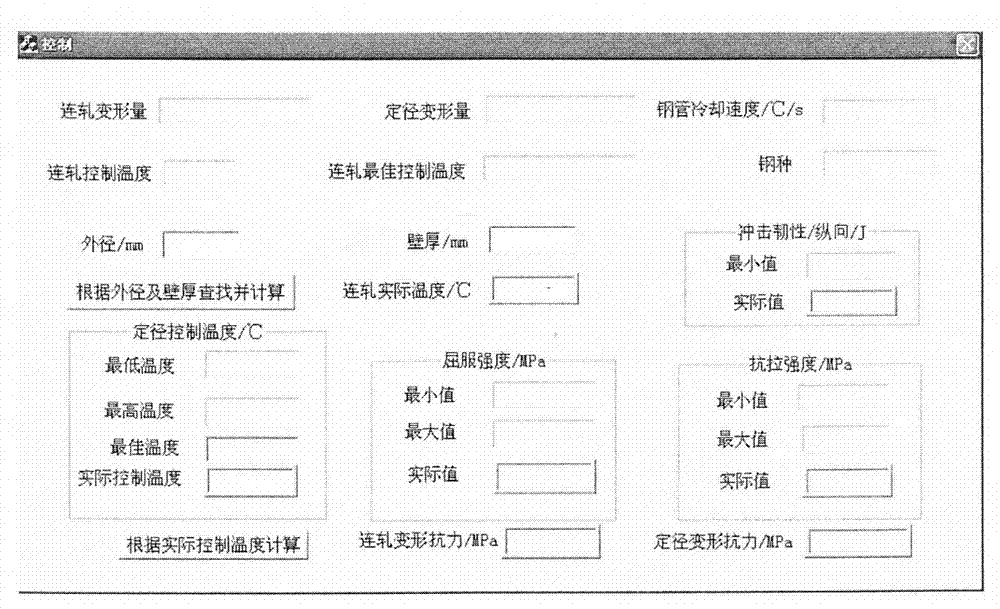

Method used

Image

Examples

Embodiment 1

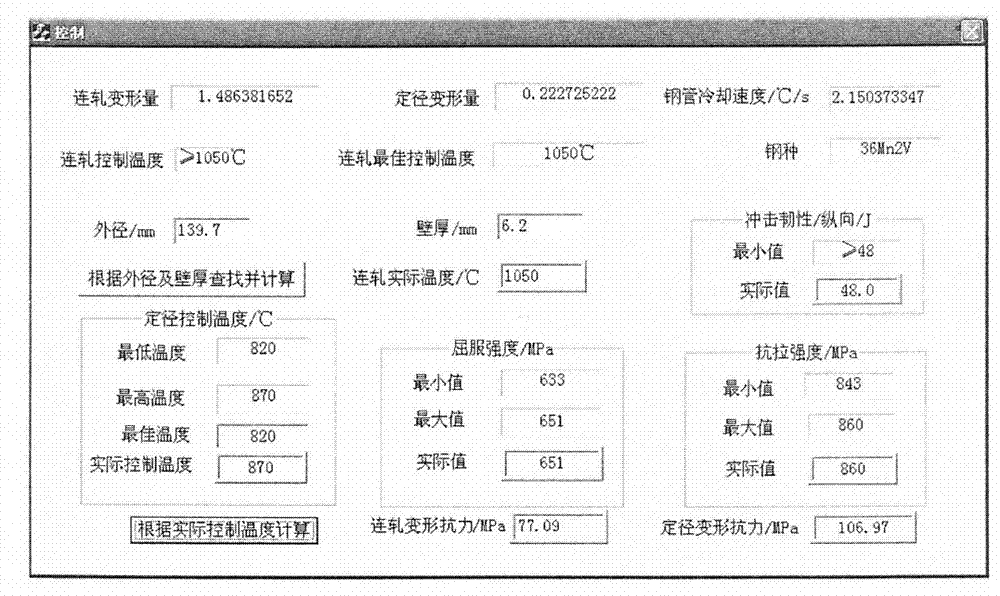

[0052] Embodiment 1. The N80-1 non-quenched and tempered seamless oil casing produced in this embodiment has an outer diameter of 139.7mm, a wall thickness of 6.2mm, a steel grade of 36Mn2V, and a production unit of ∮340.

[0053] According to Table 1 and Table 2, the basic parameters corresponding to the specification φ139.7×6.2mm are: continuous rolling deformation 1.486382, continuous rolling deformation rate 0.506940S -1 , Calibration deformation 0.222725, Calibration deformation rate 0.206606S -1 , The cooling rate is 2.150373°C / s, where: the cooling rate is calculated by the formula (1). The temperature control range of continuous rolling is 1050℃~1100℃, the best control temperature is 1050℃, the sizing temperature control range is 820~870℃, the best control temperature is 820℃. The yield and tensile strength of the product are between 633-651MPa and 843-860MPa respectively, and the impact toughness is ≥48J. When the continuous rolling and sizing temperatures are contr...

Embodiment 2

[0057] Embodiment 2. The N80-1 non-quenched and tempered seamless oil casing produced in this embodiment has an outer diameter of 244.48mm, a wall thickness of 11.99mm, a steel grade of 40Mn2V, and a production unit of ∮340.

[0058] According to Table 1 and Table 2, the basic parameters corresponding to the specification φ244.48×11.99mm are: continuous rolling deformation 1.041851, continuous rolling deformation rate 0.501069S -1 , Calibration deformation 0.145901, Calibration deformation rate 0.199547S -1 , Cooling rate 0.66787 ℃ / s. The temperature control range of continuous rolling is 1050℃~1100℃, the best control temperature is 1050℃, the sizing temperature control range is 820~870℃, the best control temperature is 820℃. The yield and tensile strength of the product are between 661-688MPa and 936-969MPa respectively, and the impact toughness is ≥46J. When the continuous rolling and sizing temperatures are controlled at 1050°C and 820°C, respectively, the corresponding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com