Optimization method aiming at SNCR denitration

An optimization method and denitrification technology, applied in the field of SNCR denitrification, can solve problems such as low denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the invention content, characteristics and effects of the patent of the present invention, the following examples are listed hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

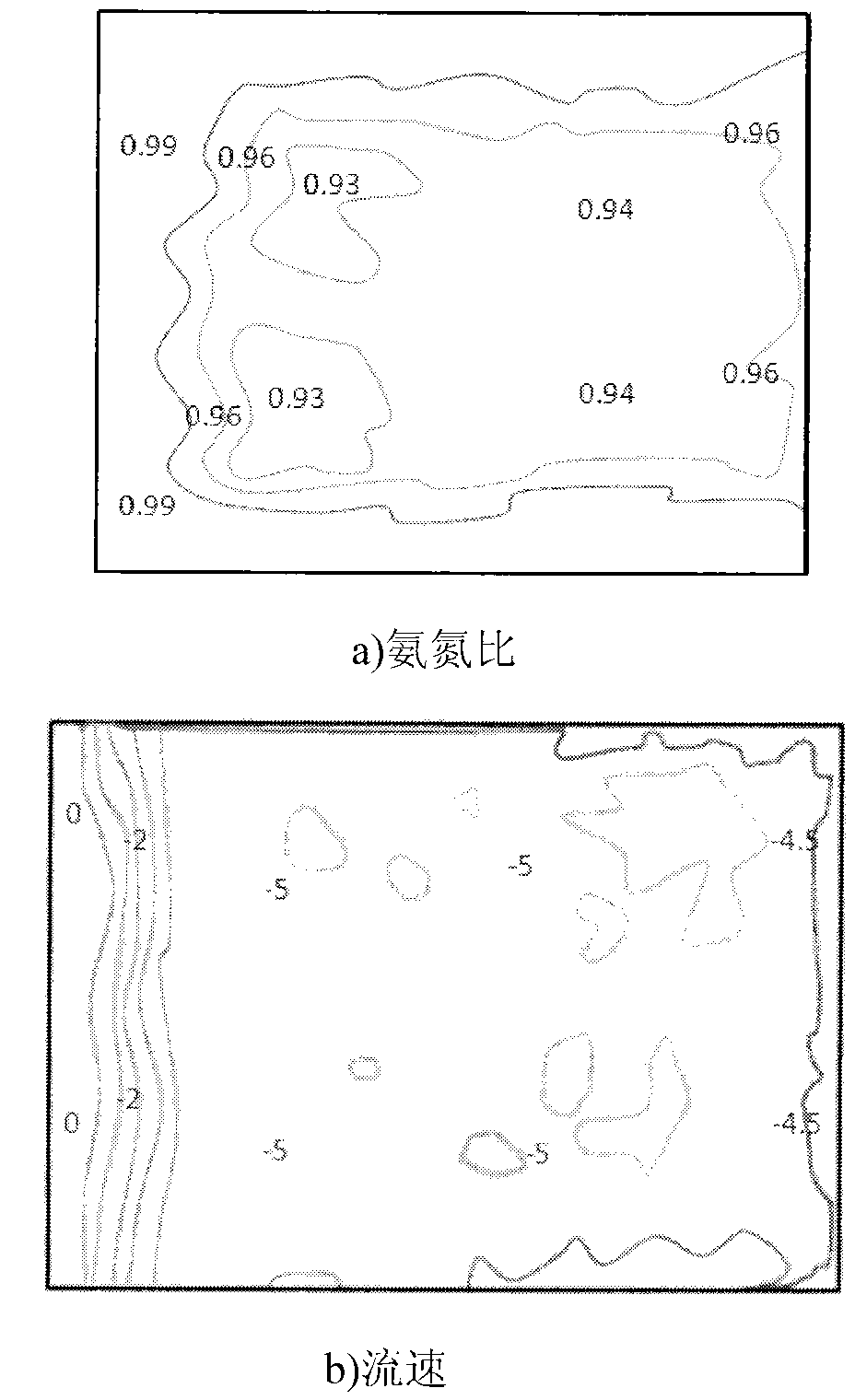

[0011] The three-dimensional numerical simulation is carried out by using the relevant calculation method of fluid mechanics, the wall is adiabatic condition, and the coupling of the velocity field and the pressure field adopts the SIMPLEC algorithm. In the calculation of mixed smoke density, viscosity coefficient, thermal conductivity and specific heat, the mixed smoke is regarded as a mixture of various ideal incompressible gases. The grid division is between 5,000,000 and 6,000,000, and the smoke velocity field and concentration distribution are calculated by a professional computer. Such as figure 1 As shown in (a), the ammonia-nitrogen ratio is 0.91 to 0.94 in most areas in the figure, and only the small area on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com