Liquid filter

A liquid filter and filter element technology, which is applied in the direction of gravity filter, chemical instrument and method, semi-permeable membrane separation, etc., can solve the problems of uneven pore size, unsuitable filter, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

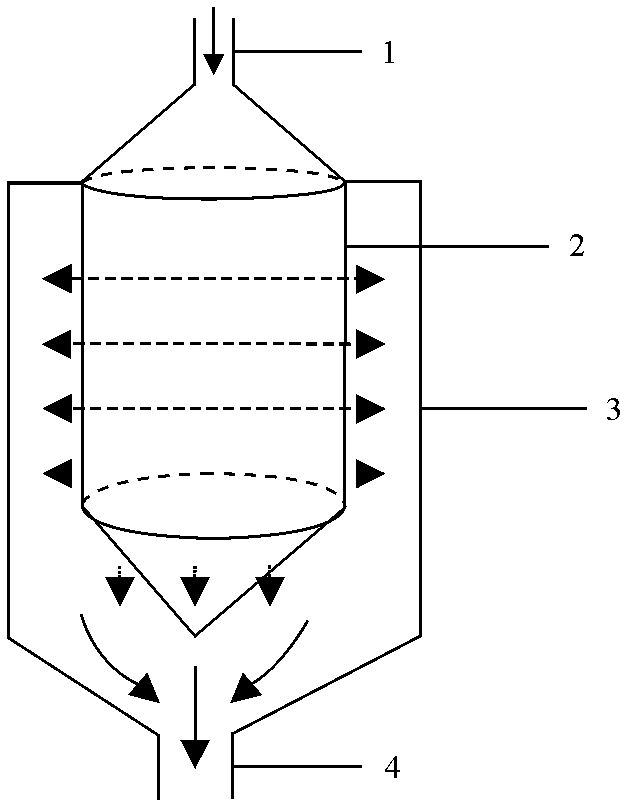

[0019] like figure 1 As shown, a liquid filter includes a filtrate collector 3 and a nuclear pore membrane filter element 2 . The middle part of the filtrate collector 3 is cylindrical, and the upper and lower parts are conical at the top, wherein the upper part is cross-linked with the liquid inlet pipe 1, and the bottom is cross-linked with the liquid outlet pipe 4. The nuclear pore membrane filter element 2 made of the heavy ion microporous filter membrane produced by the accelerator is arranged in the filtrate collector 1. The nuclear pore membrane filter element 2 is processed by a rectangular filter membrane, and the two sides are cross-linked so that the middle part is cylindrical. The upper part is connected with the liquid inlet pipe 1 through cross-linking, and the bottom part is cross-linked into a wedge shape to seal the bottom.

[0020] Among them, the nuclear pore membrane filter element 2 uses a transparent plastic film with a thickness of 5-50 microns as the b...

Embodiment 2

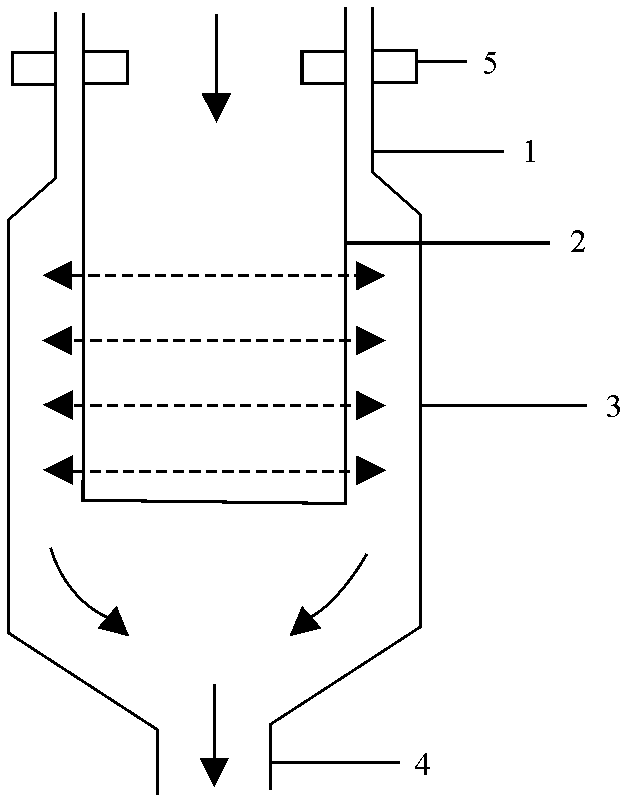

[0022] Like the liquid filter structure described in Embodiment 1, the difference is that, as figure 2 As shown, the liquid inlet pipe 1 and the liquid collector 3 are integrated, and the top of the nuclear pore membrane filter element 2 is directly cross-linked with the liquid inlet pipe 1 .

Embodiment 3

[0024] Like the liquid filter structure described in Embodiment 2, the difference is that, as figure 2 As shown, after the upper side of the nuclear pore membrane filter element 2 is cross-linked with the liquid inlet pipe 1, it is fixed with the clamp 5 again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com