Enteric-coated tilmicosin slow-release micro-capsule preparation and preparation method thereof

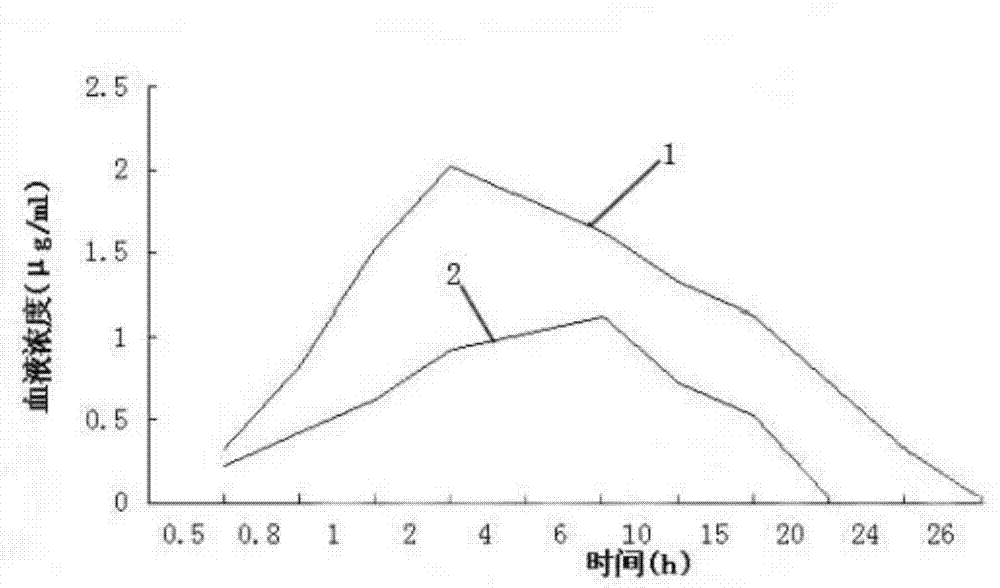

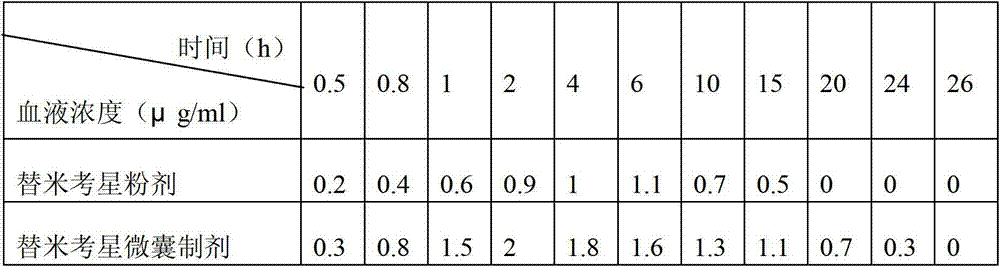

A tilmicosin and slow-release technology, which is applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, etc. Food intake and other issues, to achieve good palatability, improve drug efficacy, and avoid the first-pass effect of the liver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

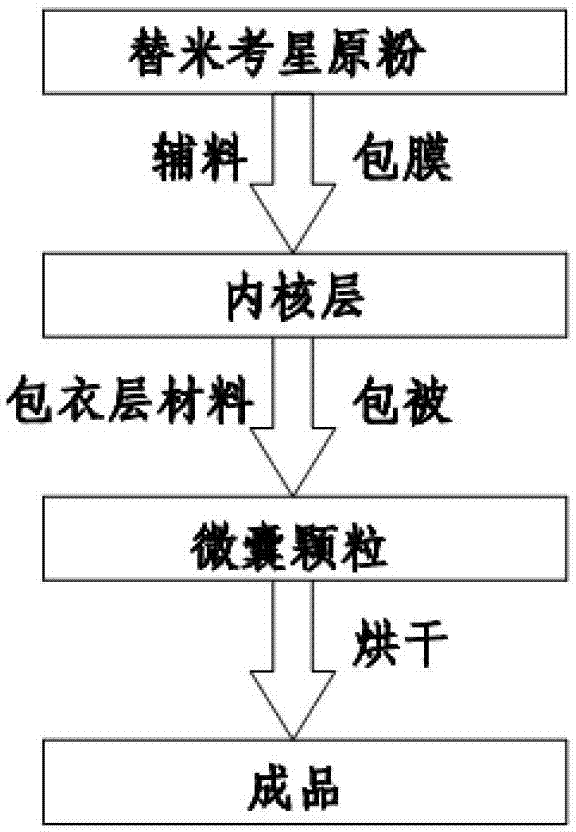

[0028] A preparation method of enteric-coated tilmicosin sustained-release microcapsule preparation, comprising the following steps:

[0029] Step 1. Add tilmicosin raw powder to the auxiliary material at a temperature of 70°C to 100°C, and coat it to form an inner core layer;

[0030] Step 2. Spray coating coating layer material on the surface of the inner core layer in the step 1 to obtain approximately spherical microcapsule particles with a diameter of 250 μm to 800 μm;

[0031] Step 3, drying the microcapsule particles prepared in step 2 to obtain the finished product.

[0032] In the present invention, the mass percentage of tilmicosin raw powder is 10% to 50%, and in this embodiment, the mass percentage of tilmicosin is preferably 10%.

[0033] Commonly used auxiliary materials are stearic acid, glyceryl monostearate, stearyl alcohol, saturated triglycerides, monoglycerides, fat powder and paraffin, in the present invention auxiliary materials are stearic acid, glycery...

Embodiment 2

[0042] Same as Example 1, the difference is:

[0043] The mass percentage of tilmicosin is 20%, and the auxiliary material is a mixture of glyceryl monostearate and fat powder, wherein the mass percentage of glyceryl monostearate is 50%, and the mass percentage of fat powder is 25%. The layer material is hypromellose phthalate, its mass percentage is 5%, and its melting temperature is 95°C.

Embodiment 3

[0045] Same as Example 1, the difference is:

[0046]The mass percentage of tilmicosin is 30%, and the auxiliary material is a mixture of glyceryl monostearate and fat powder, wherein the mass percentage of glyceryl monostearate is 40%, and the mass percentage of fat powder is 20%. The layer material is hypromellose phthalate, its mass percentage is 10%, and its melting temperature is 90°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com