Multilayer scraper-type excrement-cleaning machine turned by rope

A technology of rope drive and manure cleaning machine, which is applied in animal houses, applications, poultry industry, etc. It can solve the problems of easy wear and tear of the turning mechanism and unstable turning, so as to achieve convenient construction, overcome the difficulty of cage ventilation, and run stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

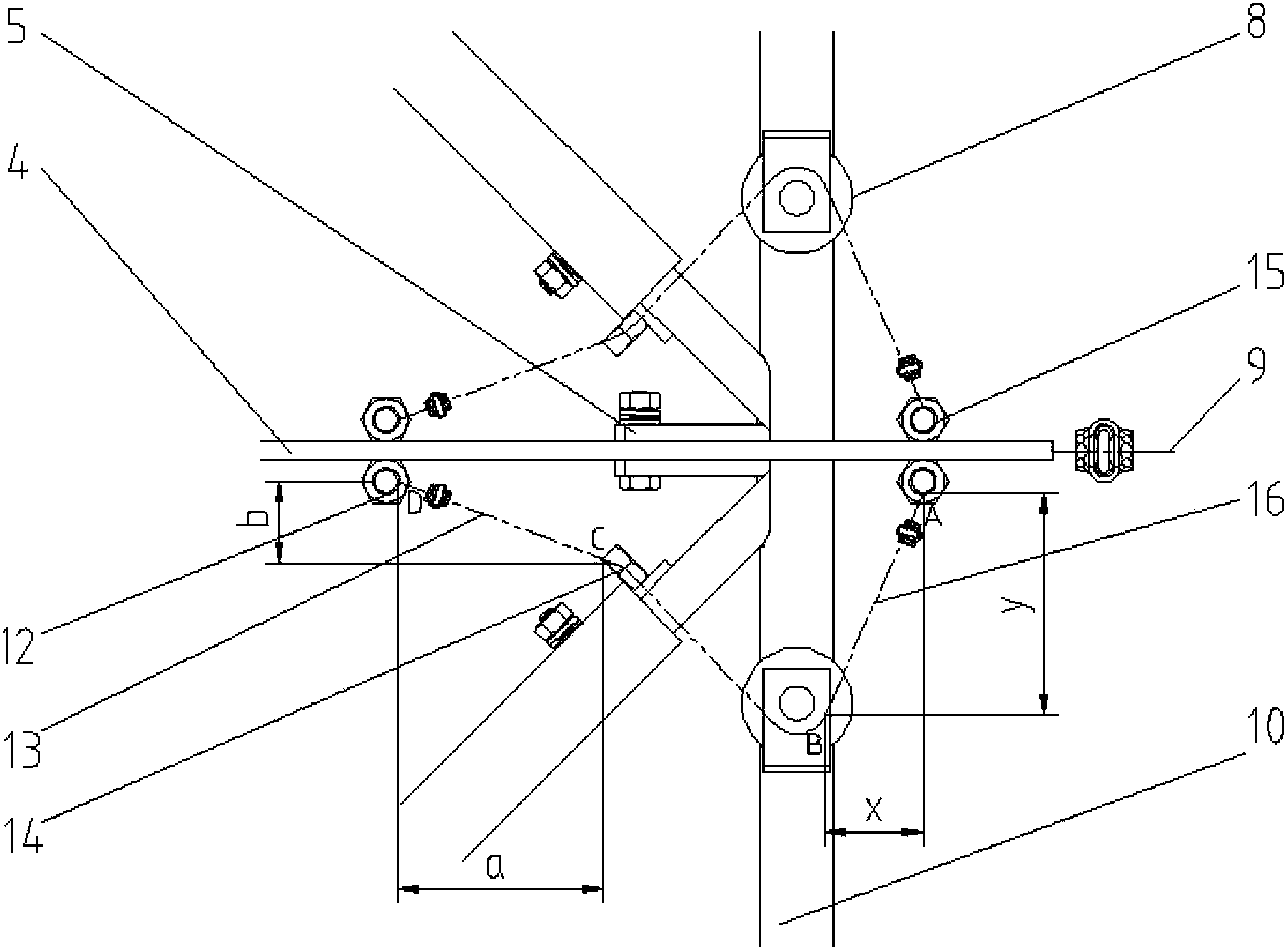

[0028] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

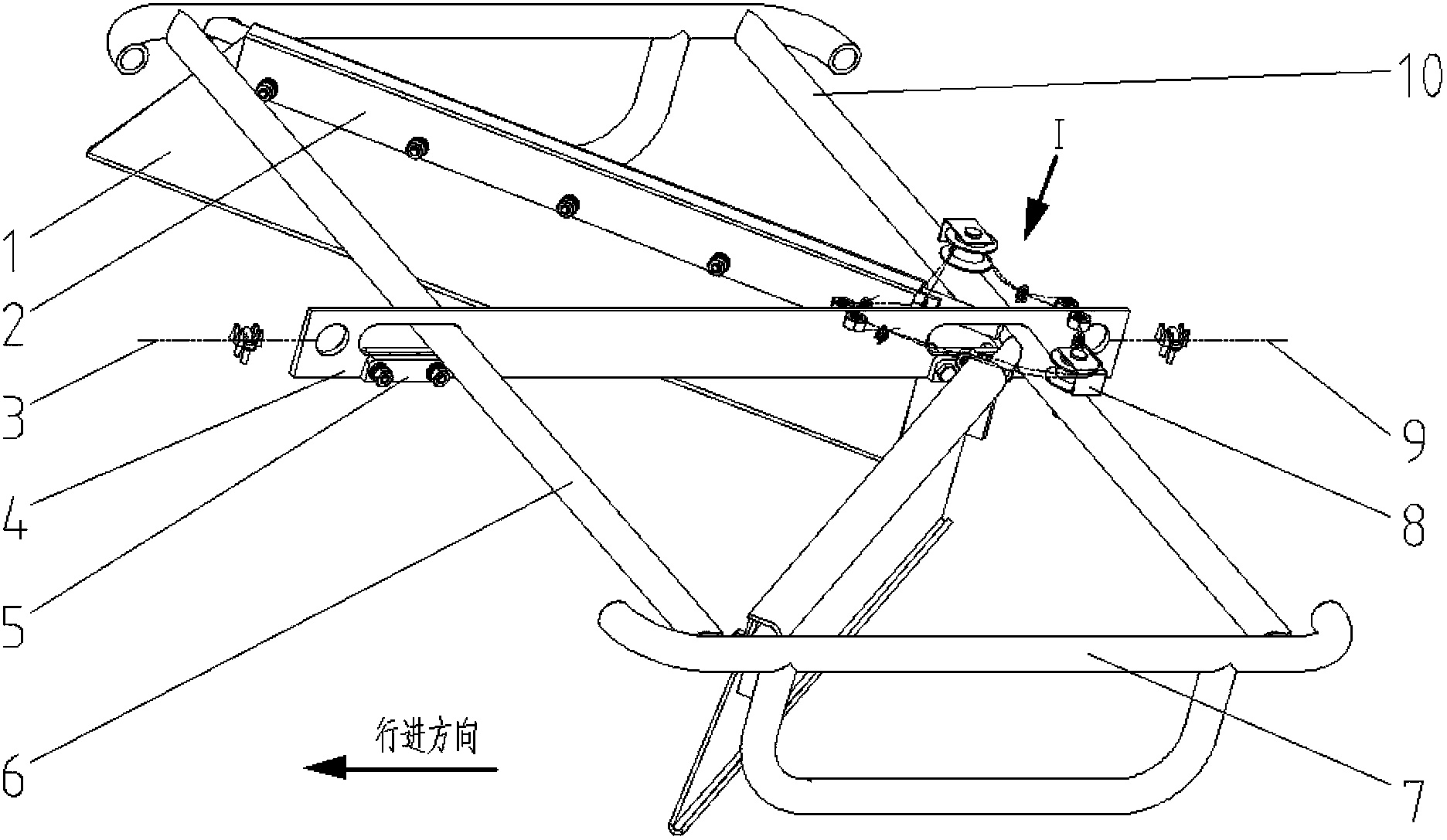

[0029] figure 1 It is a three-dimensional schematic diagram of a scraper-type manure cleaner. The multi-layer scraper-type manure cleaner mainly includes a manure cleaner frame, a traction plate 4 and two inclined scrapers 1 .

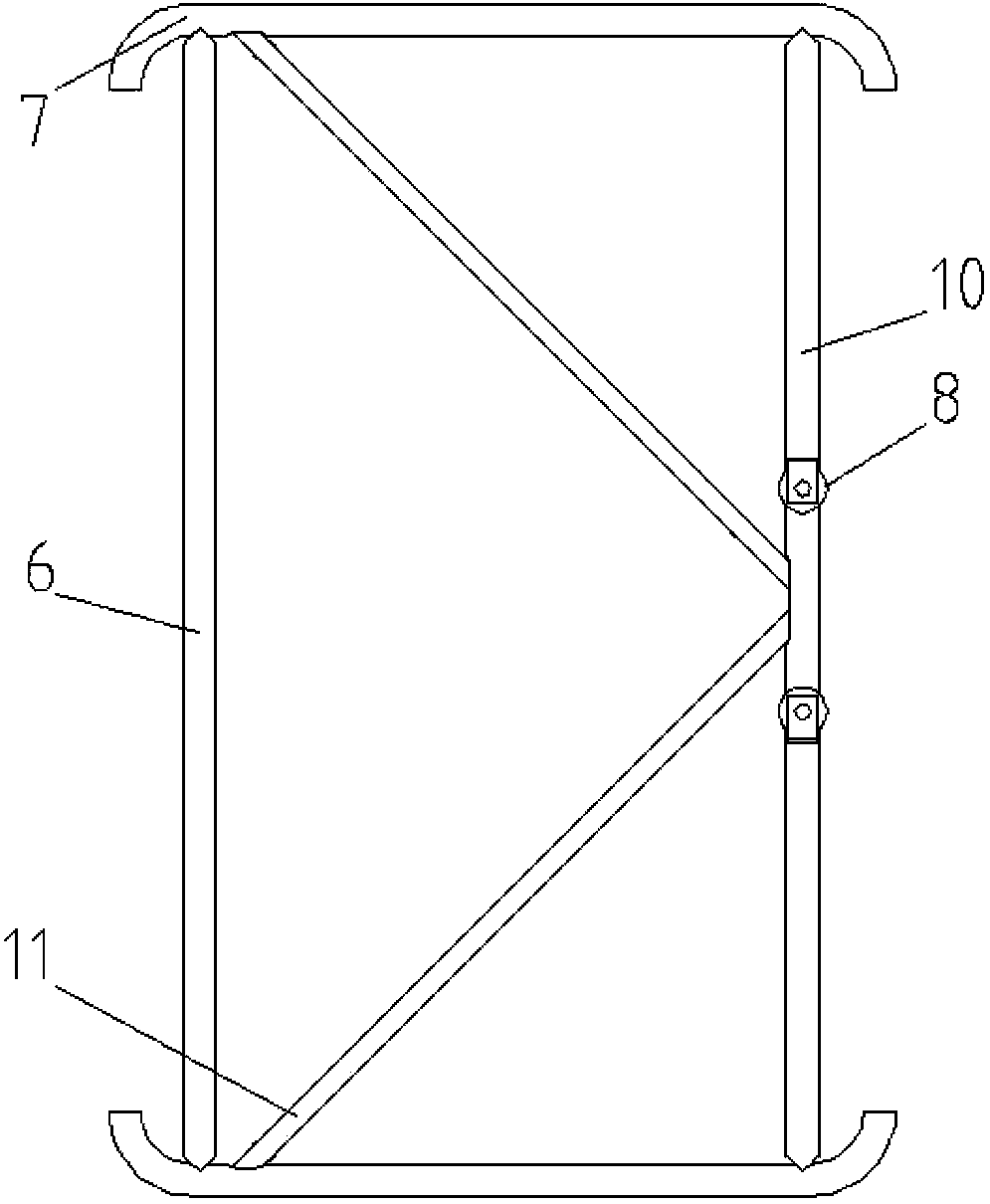

[0030] The framework of the manure cleaner is as figure 2 As shown, it is a rectangular outline. The front end of the excrement cleaning machine is the front beam 6, and the other end is the rear beam 10. The two ends of the front beam 6 and the rear beam 10 are connected by the side frame 7. The "sled" structure is raised; two oblique scraper shafts 11 are installed symmetrically on the left and right, one end of the oblique scraper shaft 11 is welded to the middle of the rear beam 10, and the other end is welded to the position of the side frame 7 close to the front beam 6. Below the scraper shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com