Integrated loudspeaker, sound box and manufacturing method

A loudspeaker and sound box technology, applied in the field of loudspeakers, can solve the problems of reducing the thickness of the loudspeaker, unsatisfactory sound effect, and difficult to satisfy modern people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

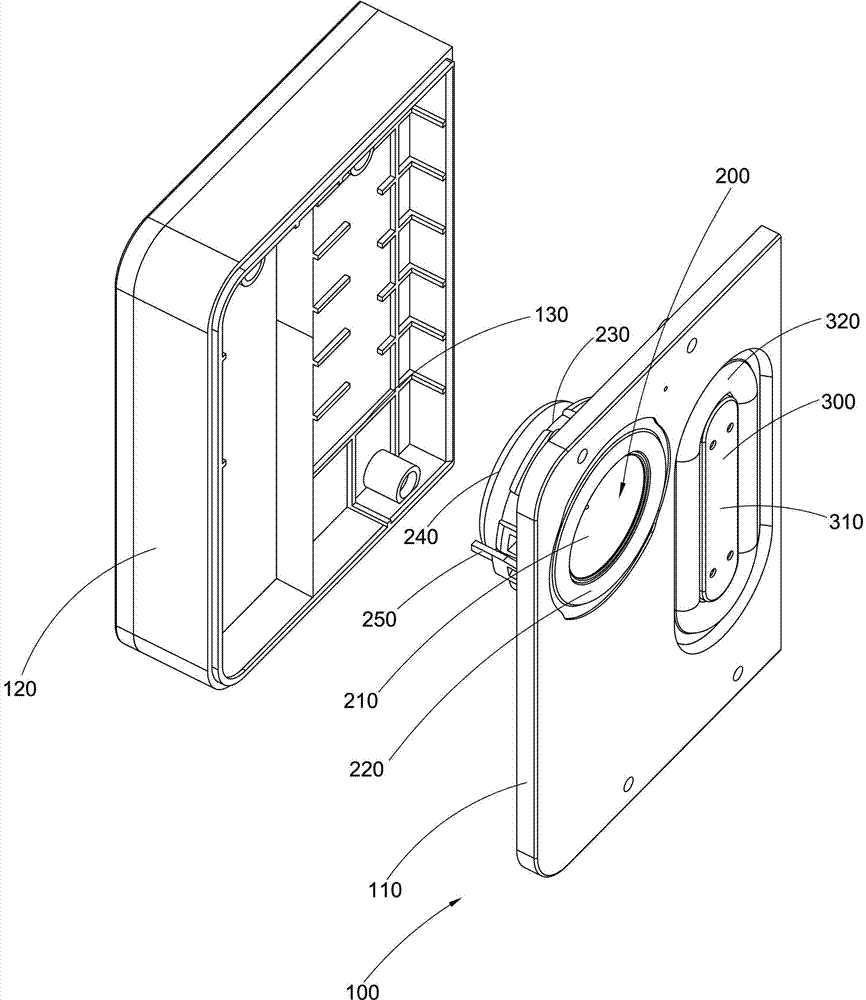

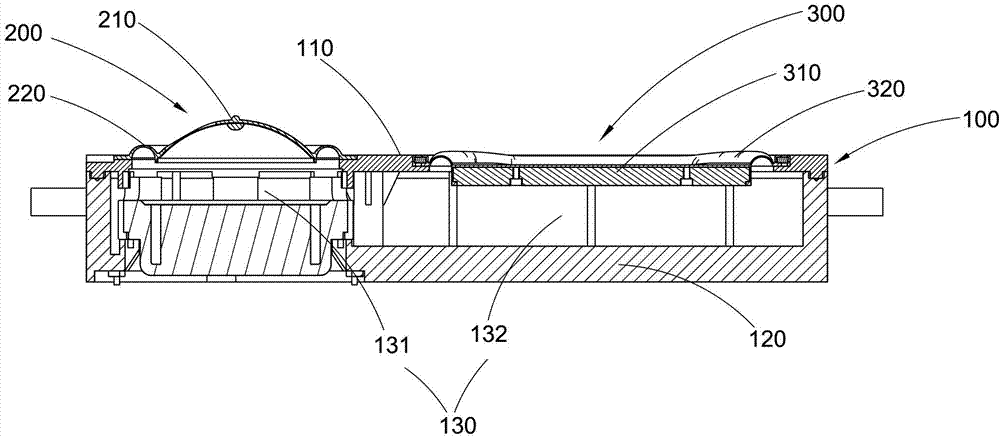

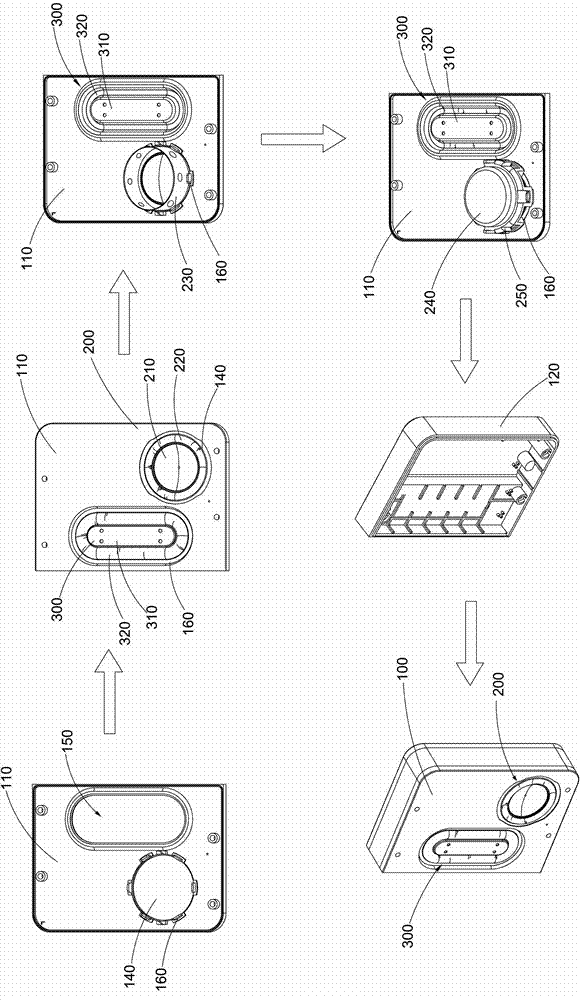

[0056] Such as Figure 1 to Figure 4 Shown is an integrated loudspeaker comprising an integrated enclosure 100 , at least one speaker system 200 , and at least one passive acoustic effector 300 according to a preferred embodiment of the present invention. The speaker system 200 and the passive sound effector 300 are mounted on the integrated housing 100 and used for vibrating and sounding, thereby providing sound effects.

[0057] More specifically, as figure 1 and figure 2 As shown, in this preferred embodiment, the integrated speaker includes one speaker system 200 and one passive sound effector 300 . The integrated housing 100 includes an integrated panel 110 and an installation panel 120 , and the integrated panel 110 and the installation panel 120 are installed together so that the integrated housing 100 forms a vibration chamber 130 . When the speaker system 200 has a sound source signal input, the speaker system 200 vibrates to generate sound, and drives the air in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com