Permanent magnet synchronous motor used for air conditioner compressor

A technology for permanent magnet synchronous motors and air-conditioning compressors, which is applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., which can solve the problem of excessive electromagnetic noise, It is difficult to obtain low-speed operation capability, large leakage reactance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

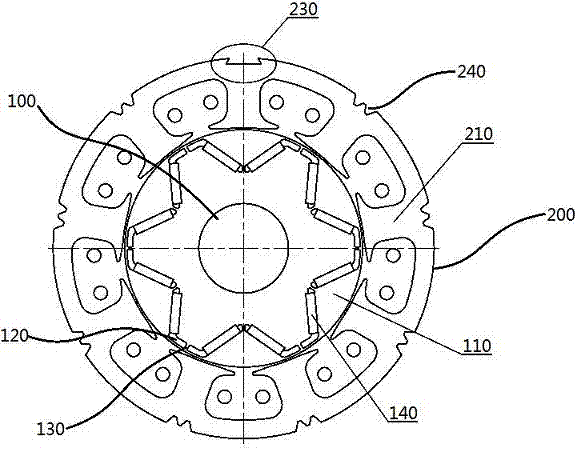

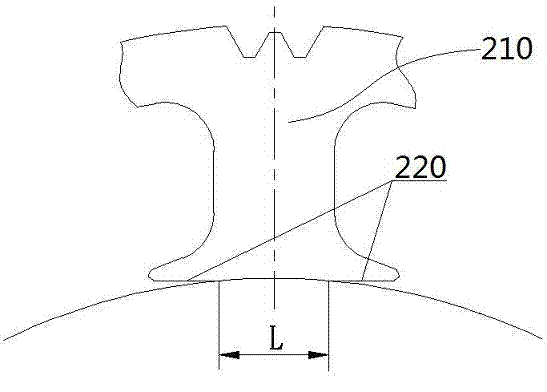

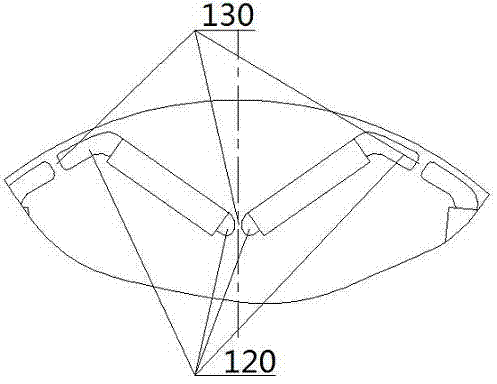

[0021] Such as figure 1 As shown, the air-conditioning compressor permanent magnet synchronous motor of the present invention includes a rotor 100 and a stator 200, the rotor 100 is an embedded magnetic steel structure, and the rotor punch 110 is provided with the same pole number as the motor. Through grooves 120, the through grooves 120 are connected by narrow strips 130 (see image 3 ); the inner circular arc of the teeth of the stator punching plate 210 is provided with symmetrical chamfering 220 (see figure 2 ).

[0022] In the present invention, the through groove 120 is a V-shaped or one-shaped groove; the width of the narrow strip 130 is 1-2 times the thickness of the rotor punch 110 .

[0023] In the present invention, the arc lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com