Intelligentized switch cabinet monitoring system and method

A switch cabinet and video surveillance technology, applied in the direction of electrical components, circuit devices, etc., can solve the problems of low intelligence, inability to perceive the asynchrony of three-phase contacts, and inability to predict the status of equipment in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

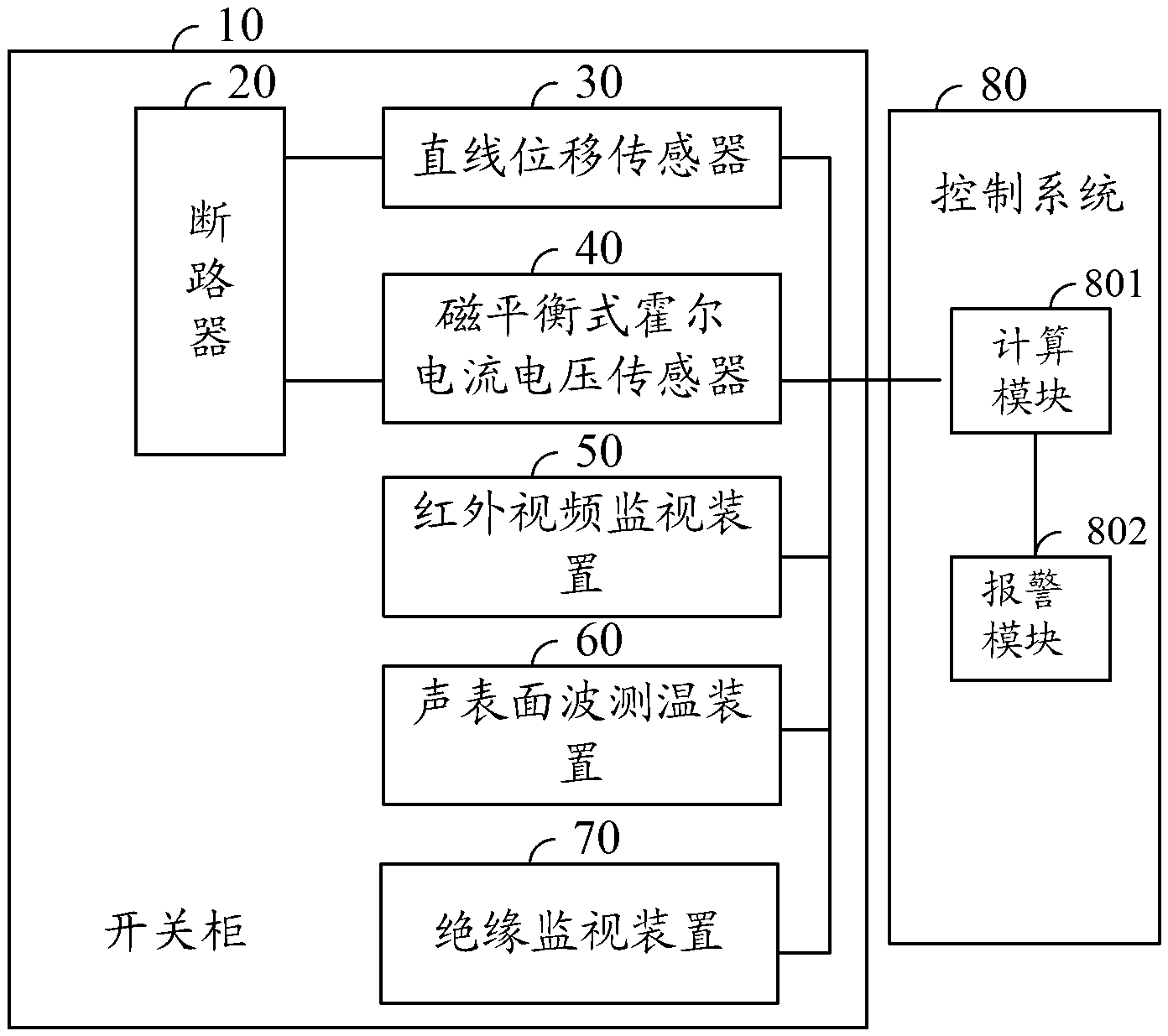

[0022] Such as figure 1 Shown is a schematic structural view of an embodiment of the intelligent switchgear monitoring system of the present invention. The switchgear monitoring system includes a switchgear 10. The switchgear 10 includes a circuit breaker 20 and a linear displacement sensor 30 (Linear Variable Differential Transformer , LVDT), magnetic balance Hall current and voltage sensor 40, infrared video monitoring device 50, surface acoustic wave temperature measuring device 60, insulation monitoring device 70, control system 80;

[0023] The linear displacement sensor 30 is connected to the insulating pull rod of the moving contact of the circuit breaker, the magnetic balance Hall current voltage sensor 40 is connected to the opening and closing coil circuit of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com