Transformer inductive reactive power stepped control device and method

A technology of inductive reactive power and control device, applied in reactive power adjustment/elimination/compensation, reactive power compensation and other directions, it can solve the problems of poor reliability, less harmonic current, and easy damage, to avoid burning phenomenon and respond Fast and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

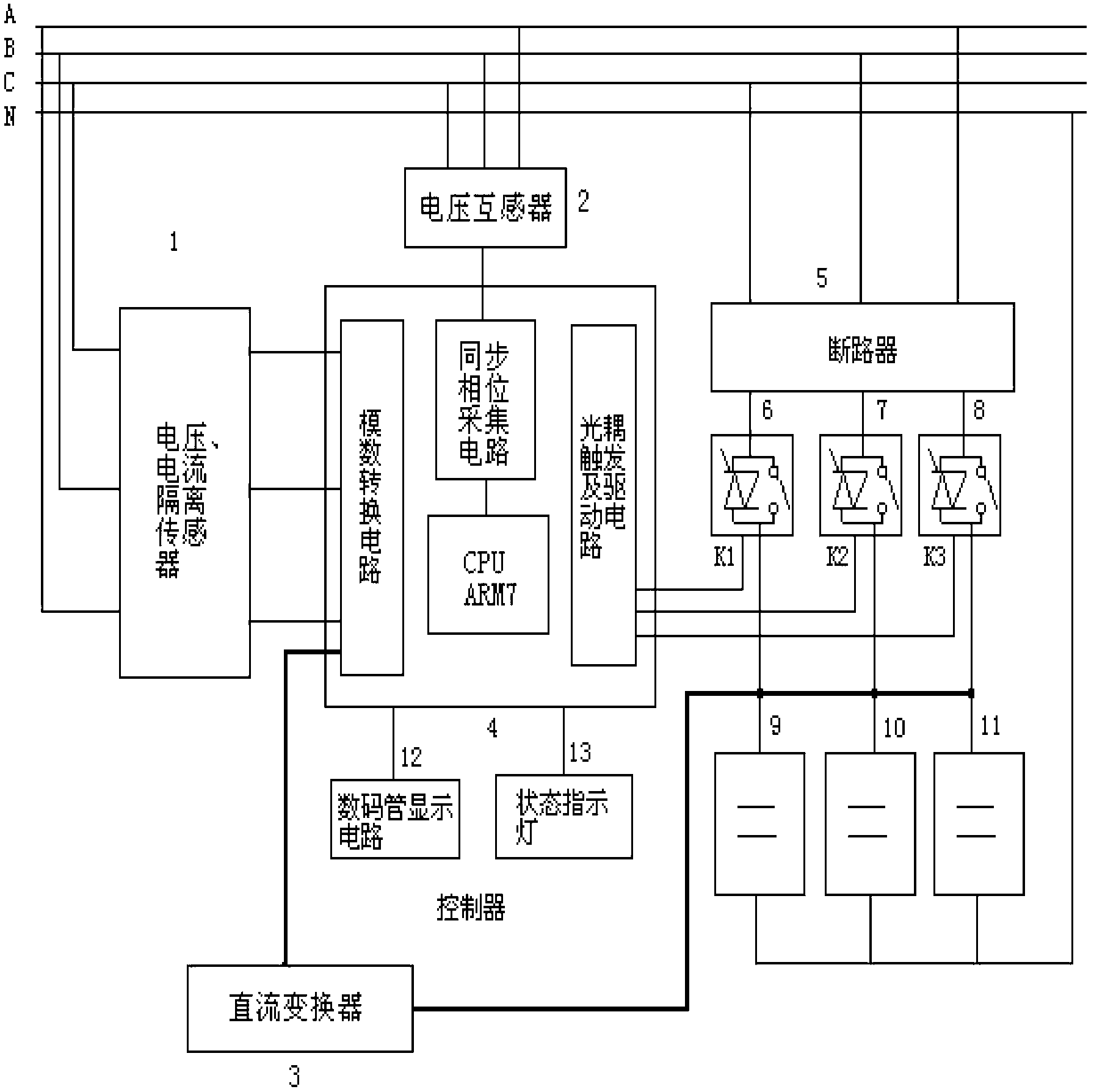

[0049] figure 1 It is a structural diagram of a stepwise control device for inductive reactive power of a transformer in a specific embodiment of the present invention. Such as figure 1 As shown, the transformer inductive reactive power step control device in the specific embodiment of the present invention includes: voltage / current isolation sensor 1, voltage transformer 2, DC converter 3, controller 4, circuit breaker 5, composite switch 6- 8. Power capacitor bank 9-11, digital tube display circuit 12 and status indicator light 13, etc.

[0050] Below is the combination figure 1 To introduce the above structural modules in detail:

[0051] The voltage / current isolation sensor 1 includes voltage / current isolation sensors corresponding to each of the three phase lines. phase voltage signal.

[0052] The voltage transformer 2 is used to step down the three-phase voltage to a low-voltage AC voltage, about 6V, as an input terminal signal of the synchronous phase acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com