Advanced detection system and method for TBM (Tunnel Boring Machine) tunnel construction based on forward three-dimensional induced polarization

A technology of induced polarization and advanced detection, which is applied in measuring devices, radio wave measurement systems, electric/magnetic exploration, etc., can solve the problems of high economic cost and time cost of drilling, large electromagnetic interference, misreporting and potential disasters and other problems to achieve the effects of saving time and economic costs, solving serious side interference, and good advance detection directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

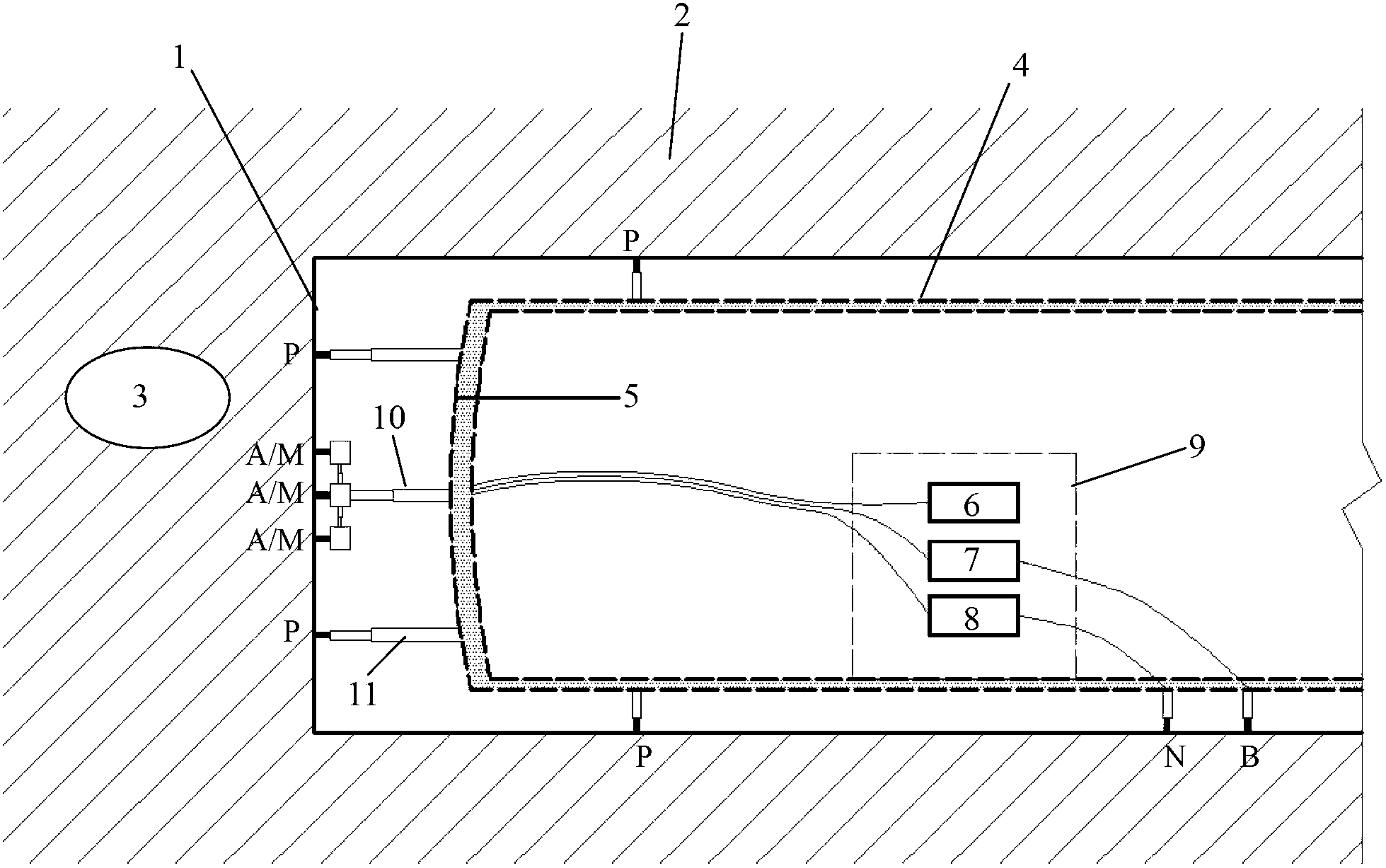

[0041] The present invention will be further elaborated below through specific examples and accompanying drawings.

[0042] All work described in the present invention is all realized in TBM main control room 9. Firstly, the layout process of power supply and measuring electrode system in TBM excavation face is introduced.

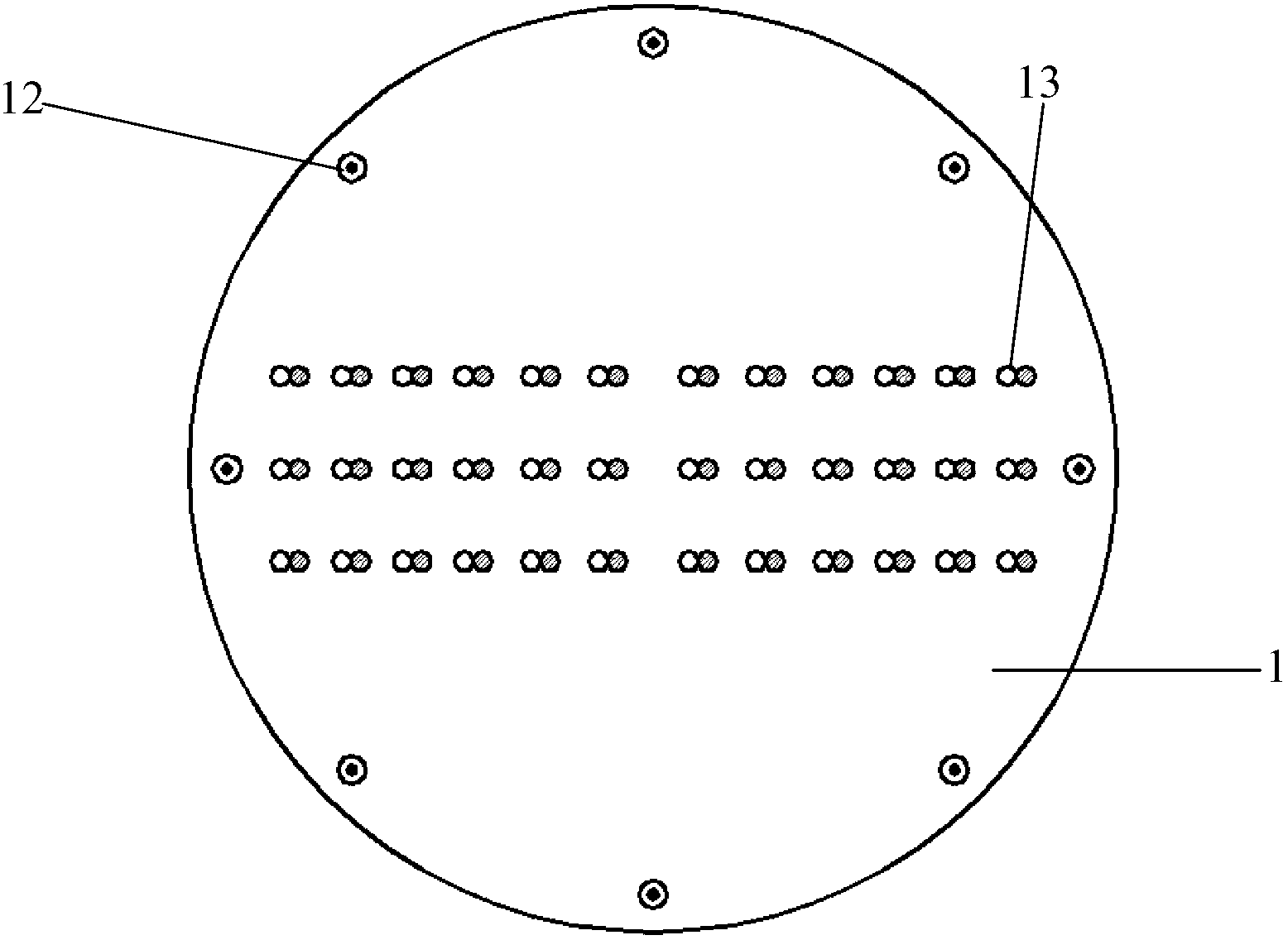

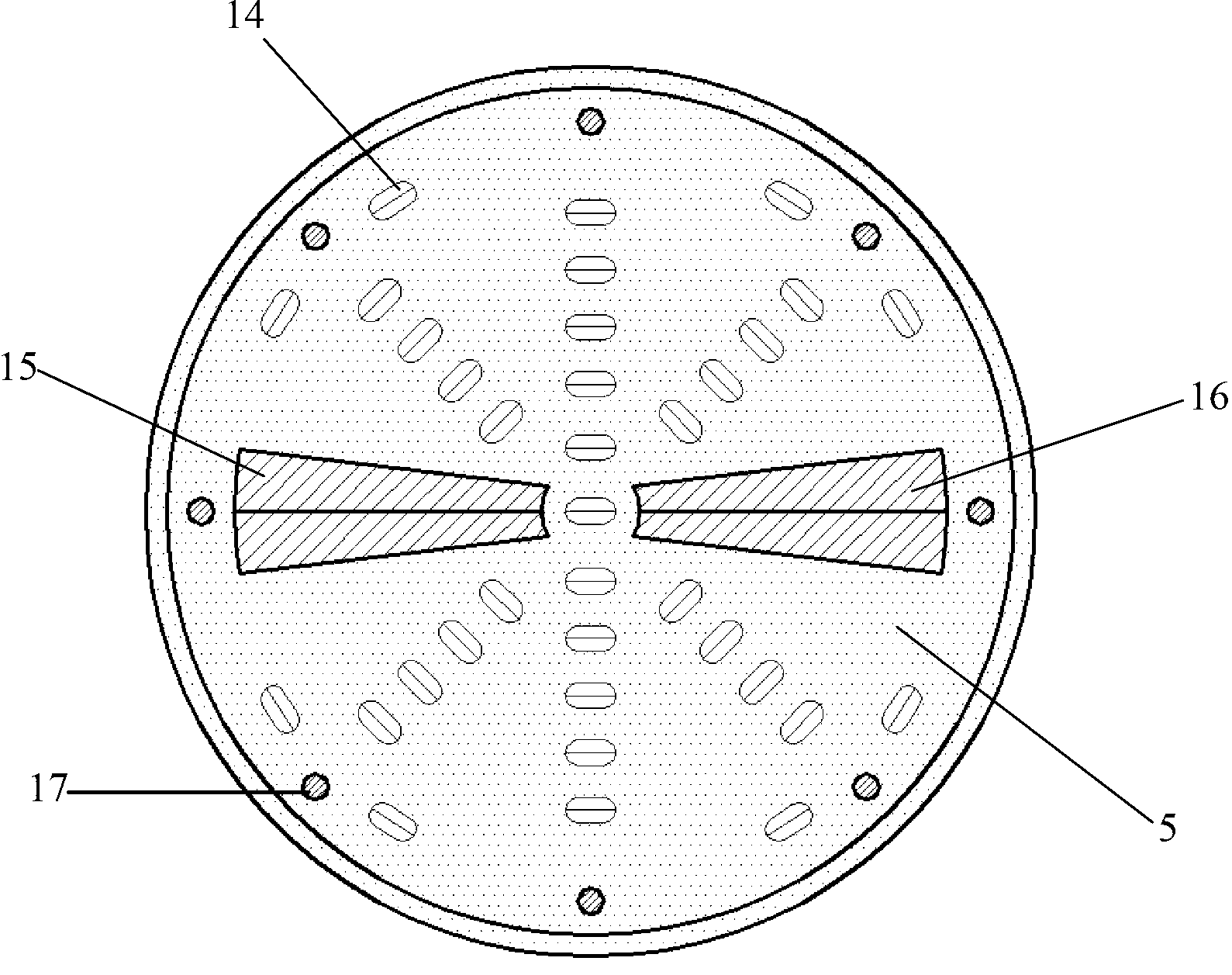

[0043] Such as figure 1 , 2 As shown, when the TBM main body 4 is advancing forward, the controller 6 controls the hatch doors of the power supply and measurement electrode compartment left compartment 15 and the power supply and measurement electrode compartment right compartment 16 on the cutterhead 5 to be in a closed state to protect the three inside the compartment. Layer rock coupling integrated electrode and its supporting device 10 are not subject to wear. After the TBM main body 4 stops excavation, before starting geological forecast work, the controller 6 controls the hatch doors of the power supply and measurement electrode compartment left c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com