Damp heat test device and method for photovoltaic assembly

A photovoltaic module, damp heat test technology, applied in the monitoring of photovoltaic systems, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of photovoltaic module simulation, difficulty in determining the power output level of photovoltaic modules, and difficulty in determining the intrinsic quality of photovoltaic modules, etc. achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

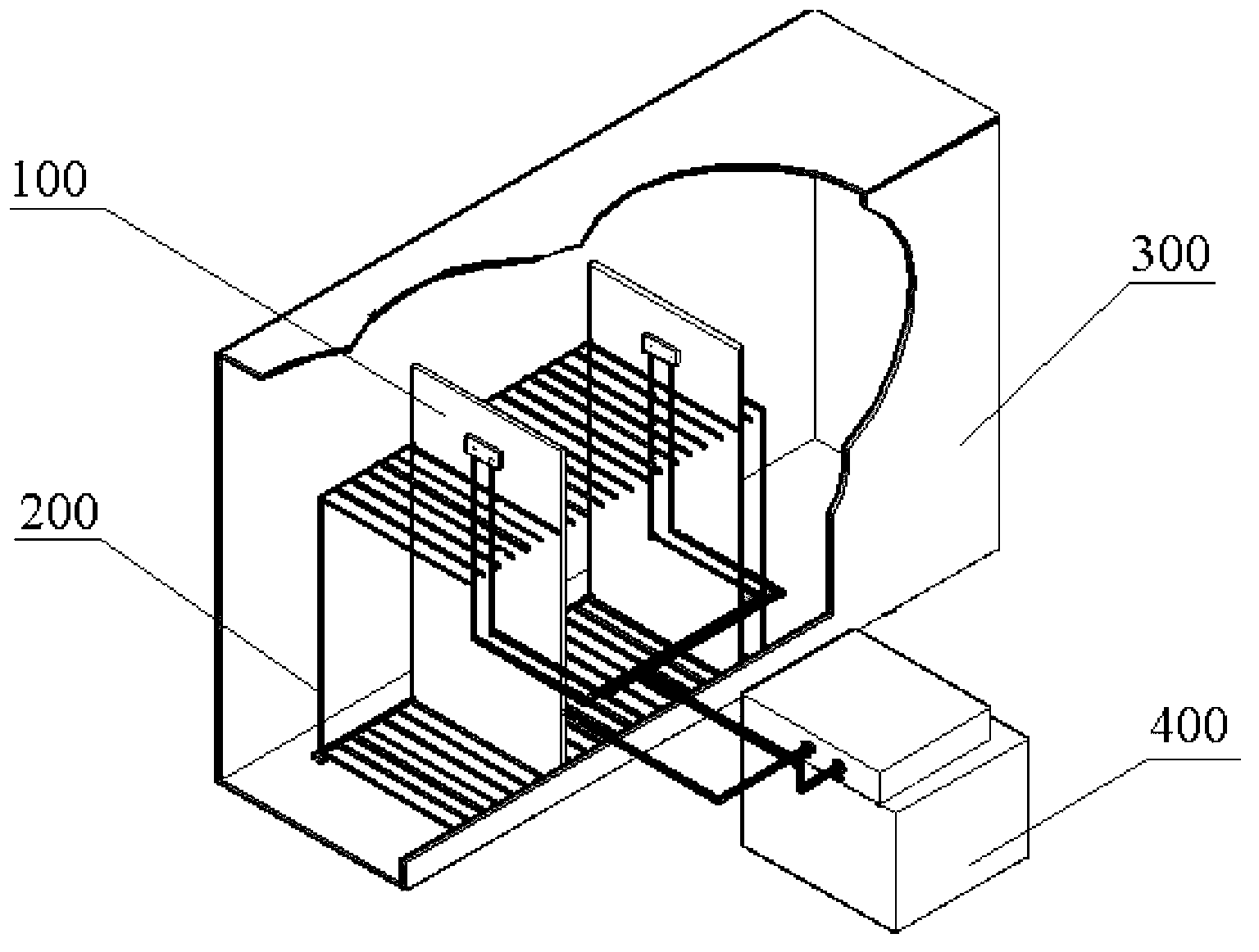

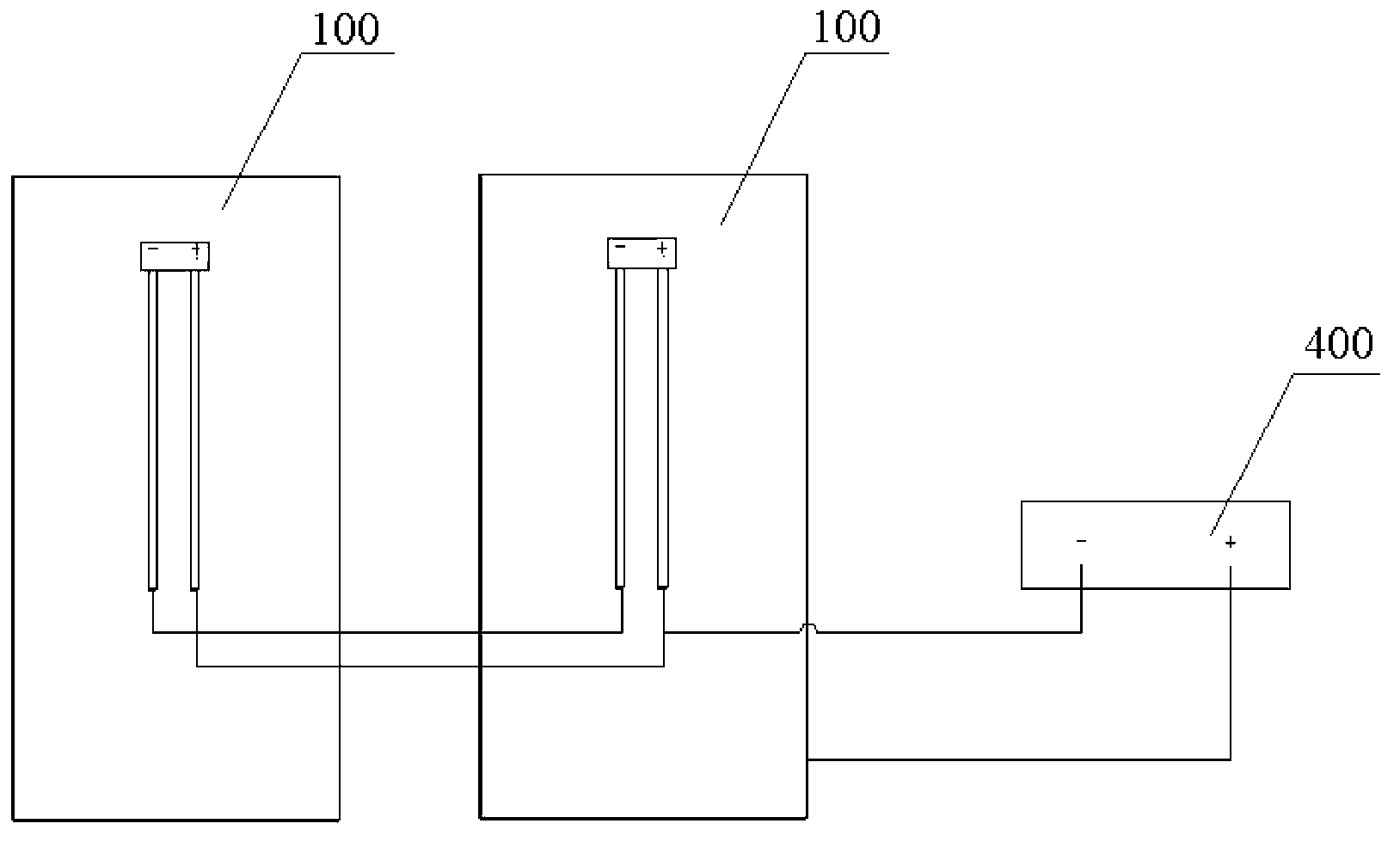

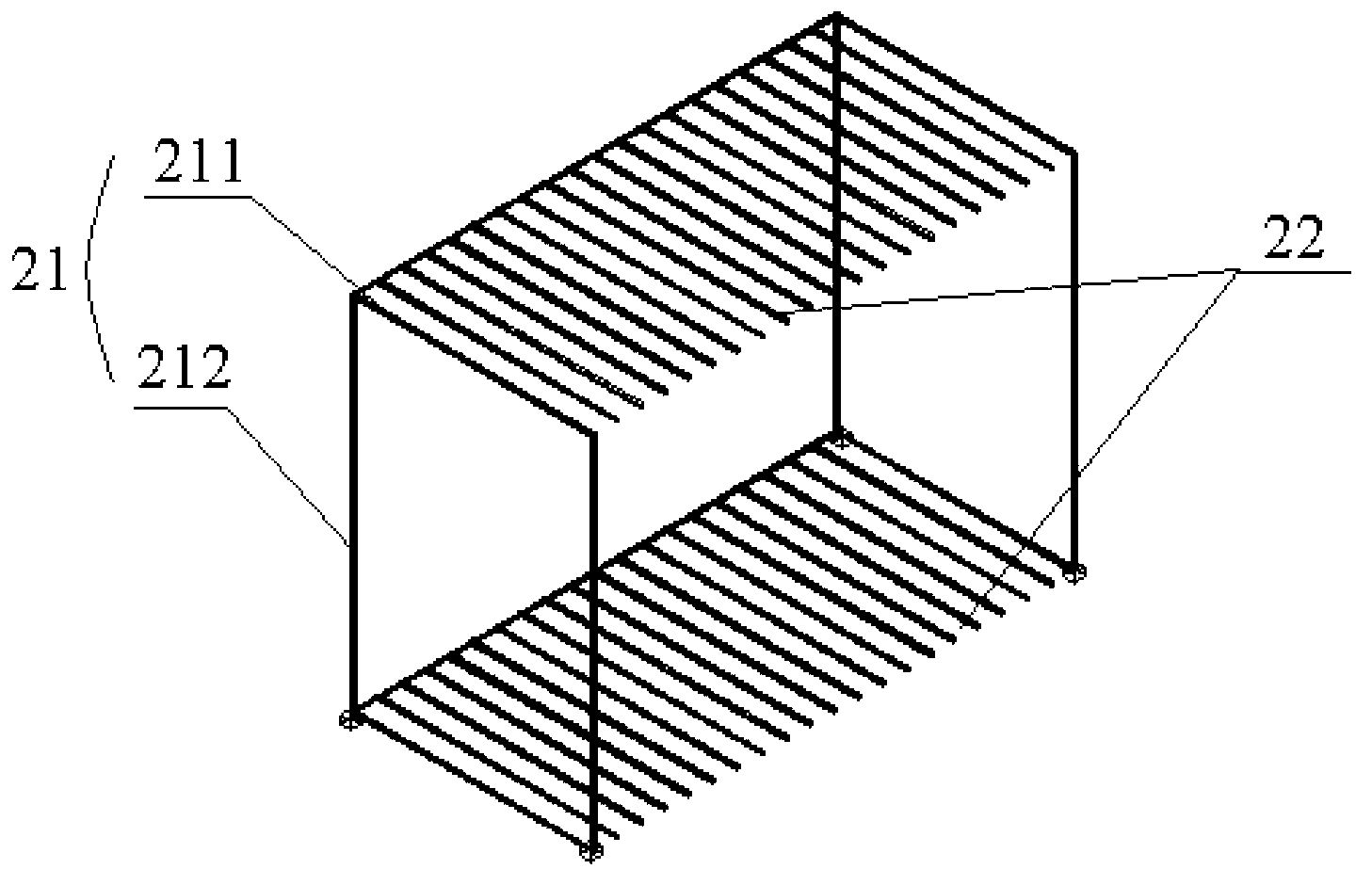

[0029] Such as figure 1 As shown, in a typical implementation of the present invention, a kind of damp heat test device of photovoltaic module 100 is provided. The damp heat test device includes a test box 300 and a power supply 400 for simulating a hot and humid environment. The test box 300 has a device to be tested The photovoltaic assembly installation part of the photovoltaic assembly 100; the power supply 400 has a power supply terminal provided inside the test box 300 to supply power to the photovoltaic assembly 100.

[0030] Using the above-mentioned damp heat test device, simulate the damp heat environment in the test chamber 300 to form the outdoor limit state of the photovoltaic mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com