A Thermoplastic Material Heating Melt Drop Combustion Test Device with Inert Gas Protection

A thermoplastic material, inert gas technology, applied in the direction of chemical analysis using combustion, investigation phase/state change, etc., can solve the in-depth quantitative analysis of the characteristics that limit the development and spread of molten liquid oil pool fire, the uncontrollable molten liquid drip rate And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

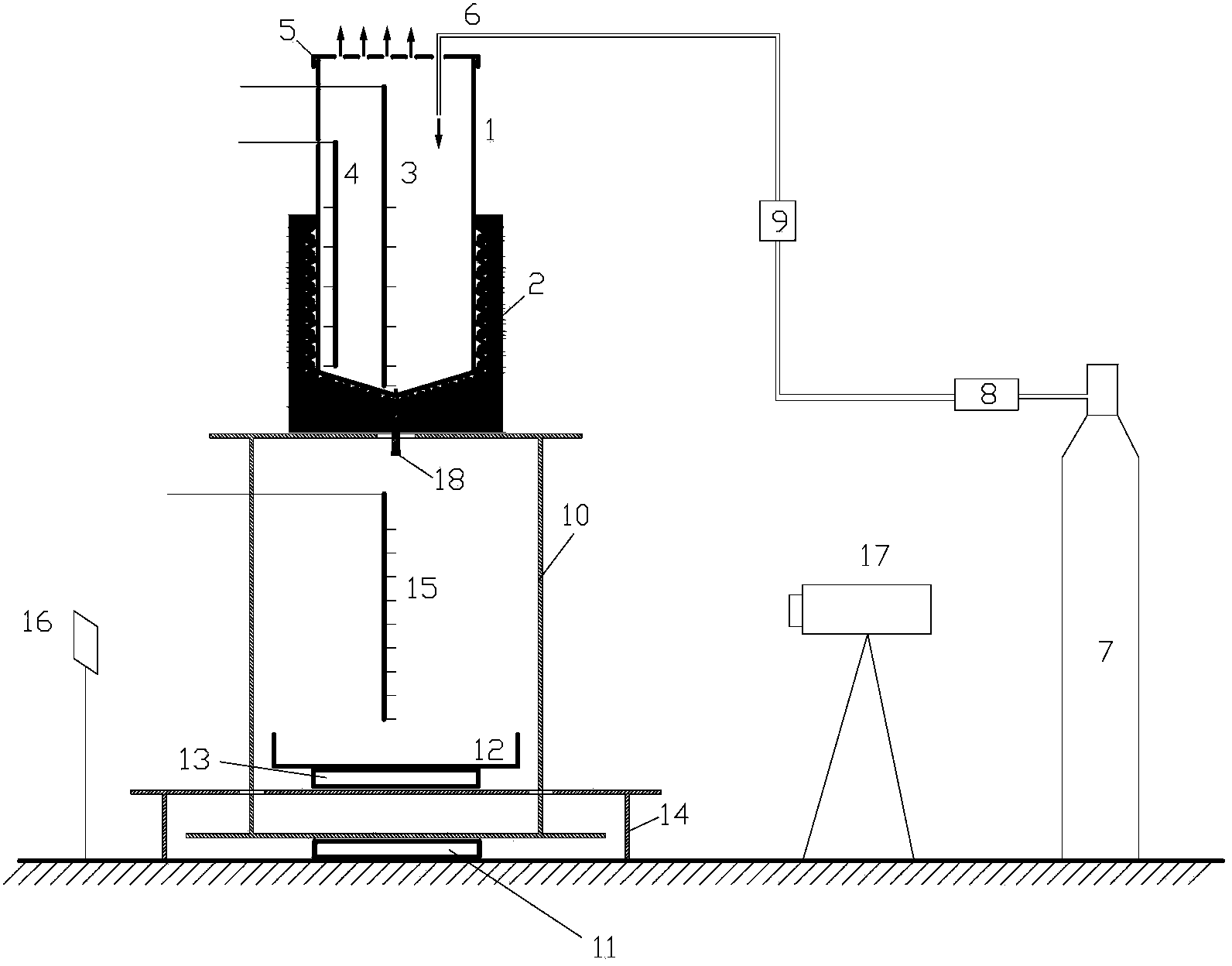

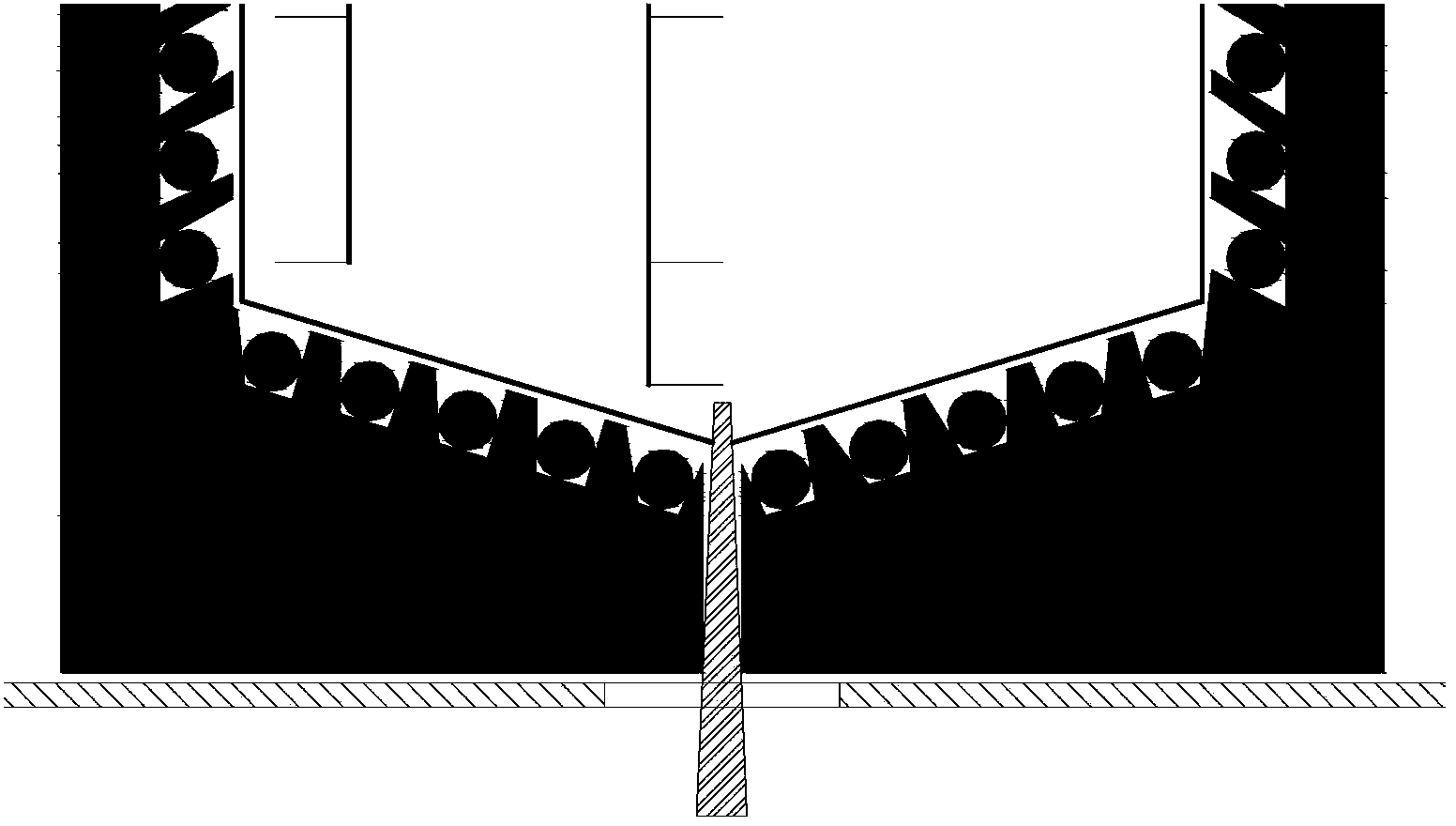

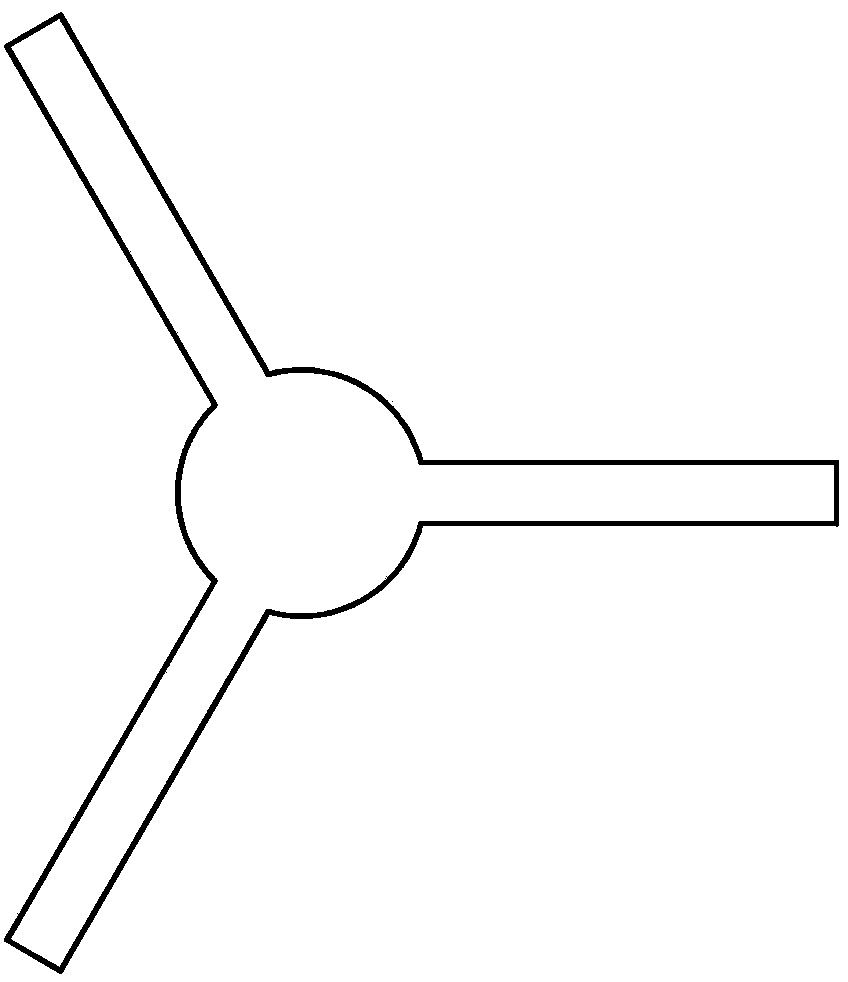

[0031] figure 1 A schematic diagram of the overall structure of the thermoplastic material heating, melting, dripping and burning test device with inert gas protection is given, figure 2 An enlarged view of the bottom opening and stopper of the metal container of the device, image 3 It is a top view of the multi-branch tank. In this embodiment, the thermoplastic material heating, melting, dripping and burning test device with inert gas protection is placed under a fume collection hood with a smoke exhaust fan, so that the pyrolysis products in the metal container and the combustion fume from the oil pan at the bottom can pass through the fume collection The hood vents to the outside.

[0032] Such as figure 1 As shown, a stainless steel metal container 1 with a conical bottom is placed in an electric heating furnace 2 . For example: the bottom and side walls of the metal container 1 are heated by the electric heating wires of the electric heating furnace 2, and the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com