Hydraulic variable-stroke finely-tunable positioning locking type hydraulic cylinder testing rack

A technology of positioning and locking and test bench, which is applied in the field of hydraulic pressure, can solve the problems of unsuitable installation and testing, poor guarantee of hydraulic cylinder concentricity, low utilization rate of equipment, etc., so as to facilitate remote control and nearby precise fine-tuning, convenient Automatic or manual positioning, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

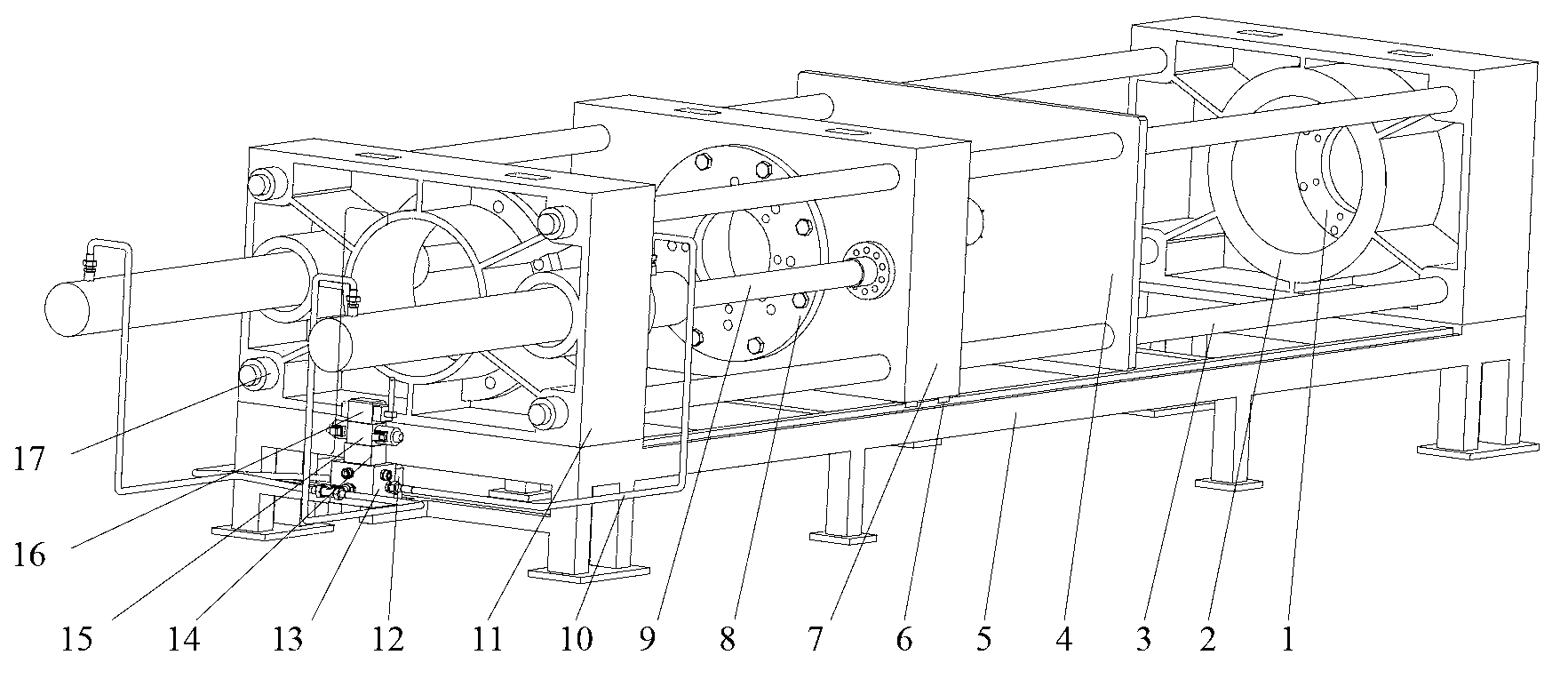

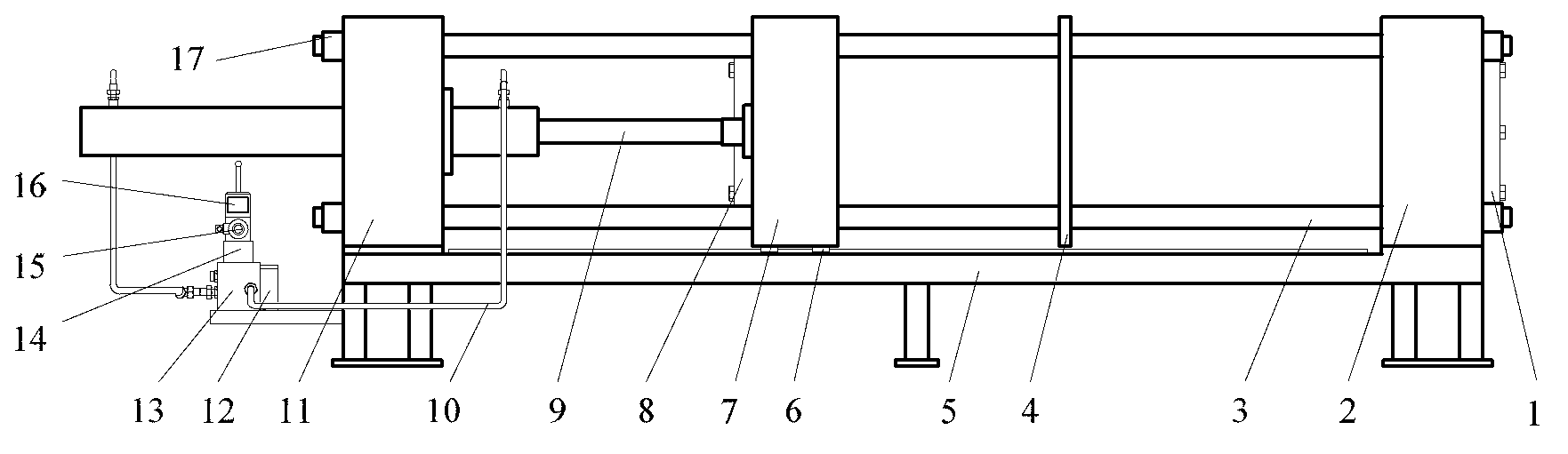

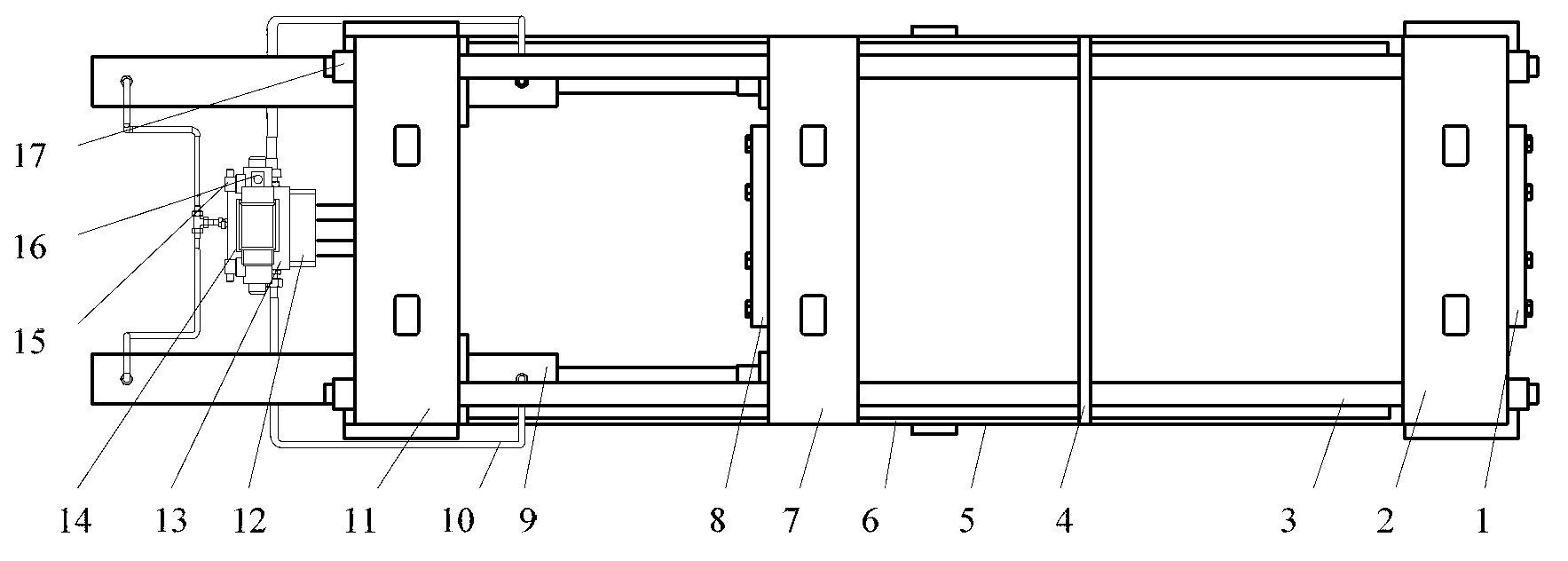

[0060] A kind of hydraulic variable stroke can be fine-tuned positioning locking type hydraulic cylinder test bench according to the embodiment of the present invention is as follows: figure 1 , figure 2 , image 3 As shown, the hydraulic cylinder test bench adopts a frame structure composed of casting plates and optical axes. The distance between the tested hydraulic cylinder mounting plate and the loading hydraulic cylinder mounting plate is realized by the two positioning hydraulic cylinders and the hydraulic control system installed on it. Adjustable for test versatility with this bench.

[0061] In this embodiment, the front plate (2) and the rear plate (11) are fixed on both ends of the optical axis (3) by lock nuts (17), and the middle plate (7) and the guide support plate (4) are installed on the front plate (2) and the rear plate (11), and can slide freely on the optical axis (3), two positioning hydraulic cylinders (9) are installed on the rear plate (11), and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com