High-pressure-intensity external pulse excitation device for T-shaped burner

A pulse excitation and burner technology, applied in jet propulsion, rocket engine, machine/engine, etc., can solve the problems of difficult self-excited oscillation, inability to accurately measure the propellant pressure coupling response function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

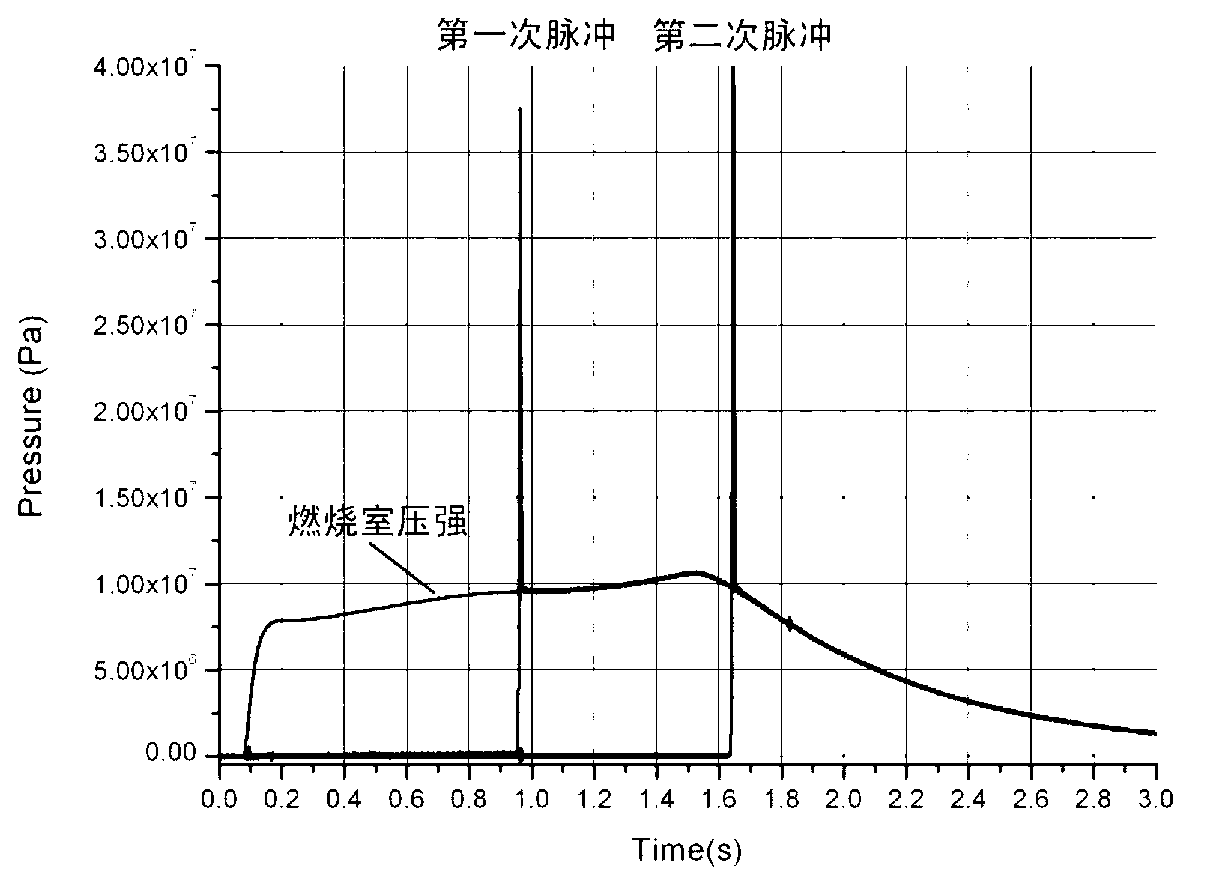

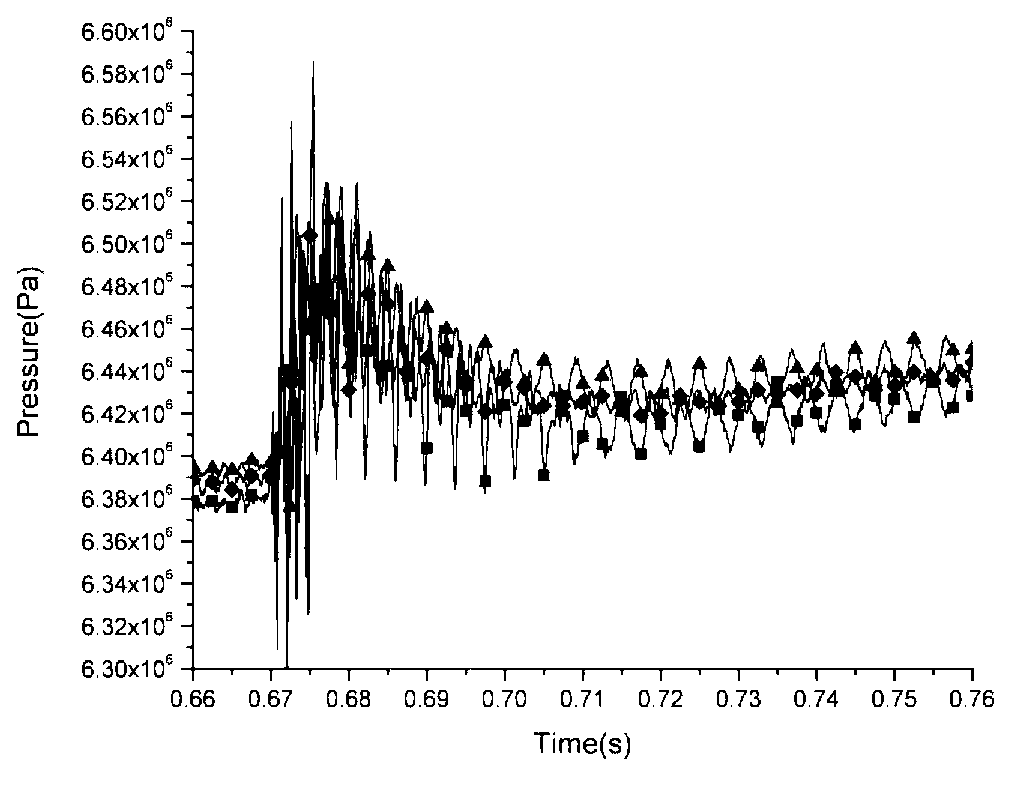

[0022] In this embodiment, under the condition that the working pressure of the T-shaped burner is 10MPa, according to the working time of the propellant, the working condition of the pulse trigger excitation is observed through a high-precision, multi-channel ignition timing control device. During the experiment, a total of two pulse-triggered excitations were carried out, the first time was at the middle of the T-shaped burner operation, and the second time was at the moment when the propellant had just finished burning. The amount of ignition powder in the pulser is 5g, and a high-temperature gas of 40MPa can be generated in the pulser.

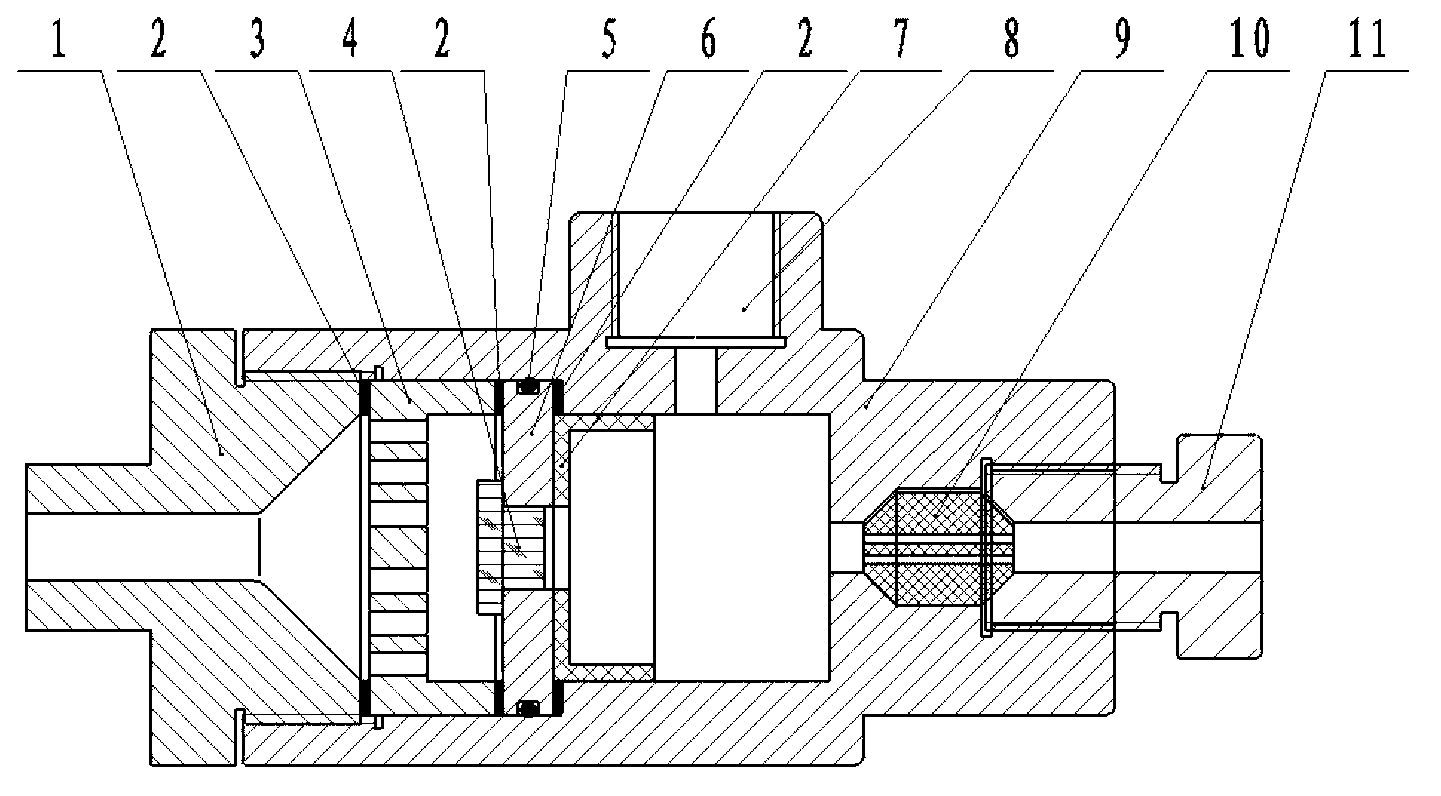

[0023] This embodiment includes a pulser nozzle 1, a pulser baffle 3, a plug 4, an O-ring 5, a sealing pressure bearing piece 6, an insulating sleeve 7, a pressure measuring seat 8, a pulser housing 9, and an ignition sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com