Self-walking shale gas drilling machine

A self-propelled technology for shale gas, applied in rotary drilling rigs, percussion drilling, rotary drilling, etc., can solve problems such as difficulty in improving work efficiency, waste of manpower and material resources, inconvenient movement, etc. The effect of reduced labor intensity, labor saving and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

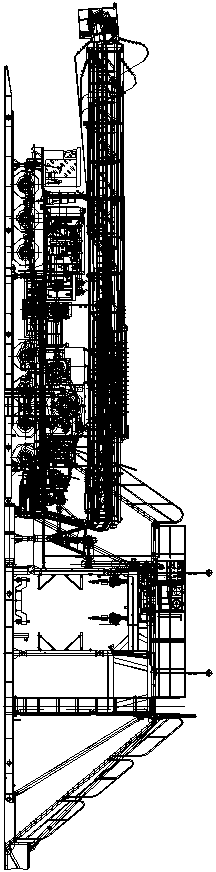

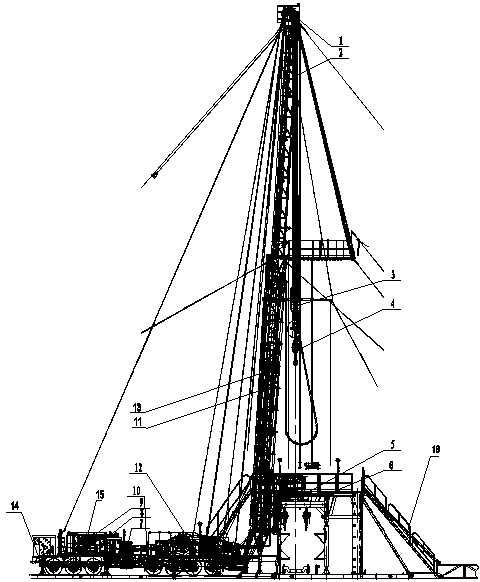

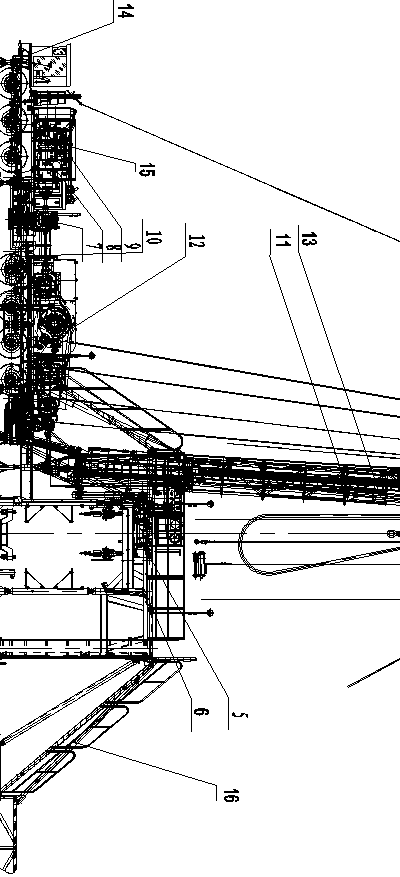

[0020] Such as Figure 1-3 As shown, the self-propelled shale gas drilling rig includes a crown block 1, a derrick 2, a turntable 5, a drill floor 6, a drawworks 12, a vehicle chassis 10, a power mechanism and a hydraulic system, and the derrick 2 is arranged on the vehicle On the chassis 10, the crown block 1 is arranged on the top of the derrick 2 and is connected with the winch 12 arranged on the chassis 10 of the vehicle through a wire rope. Hook 3 is connected with winch 12 by wire rope.

[0021] The power mechanism of this self-propelled shale gas drilling rig includes two diesel engines 9, two hydraulic transmission boxes 8 and a gear box 7 arranged on the carrier vehicle chassis 10, and the two diesel engines 9 and two hydraulic transmission After the boxes 8 are respectively connected, they are jointly connected with the gear parallel box 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com