Low-temperature sintering method of high potential gradient voltage-sensitive ceramic material

A low-temperature sintering and pressure-sensitive ceramic technology, which is applied in the field of high-potential gradient zinc-bismuth oxide-based pressure-sensitive ceramic materials and their low-temperature sintering, can solve the problems of limited application, high price, and difficulty in preparing ceramic powder materials in large quantities. The effect of low cost, high performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

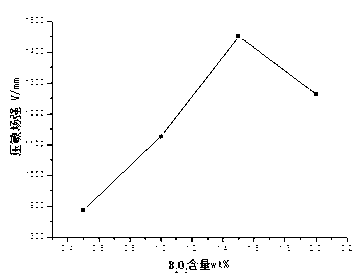

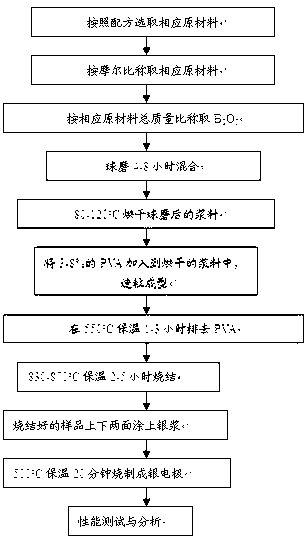

[0034] Example 1: With ZnO, Bi 2 o 3 , Sb 2 o 3 、Co 2 o 3 , MnO 2 、Cr 2 o 3 and B 2 o 3 As raw material, according to the molar ratio of 97.5% ZnO, 0.5% Bi 2 o 3 , 0.5%Sb 2 o 3 , 0.5%Co 2 o 3 , 0.5%MnO 2 , 0.5%Cr 2 o 3 Weigh, then add and (97.5%ZnO+0.5%Bi 2 o 3 +0.5%Sb 2 o 3 + 0.5%Co 2 o 3 +0.5%MnO 2 +0.5%Cr 2 o 3 ) mass ratio is 0.5%, 1.0%, 1.5%, 2.0% of B 2 o 3 . According to the conventional solid-phase synthesis method, batching, ball milling and mixing for 8 hours, drying, adding 3wt% PVA binder, molding, plastic discharge (550°C, 1h), and sintering at 850°C for 5 hours, the pressure-sensitive ceramics can be formed, as shown in the following table 1 In order to obtain the electrical properties of the varistor ceramics under this formula.

[0035]

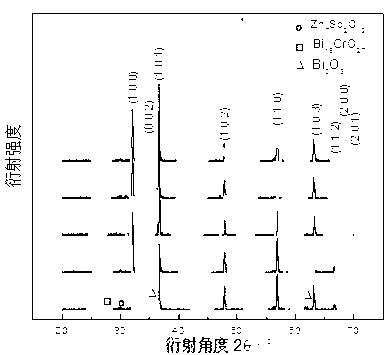

[0036] figure 2 In order to utilize the ZnO-Bi prepared in Example 1 of this technical solution after being incubated at 850°C for 5 hours 2 o 3 The XRD analysis spectrum of the varistor ...

Embodiment 2

[0037] Example 2: With ZnO, Bi 2 o 3 , Sb 2 o 3 、Co 2 o 3 , MnO 2 、Cr 2 o 3 and B 2 o 3 As raw material, according to the molar ratio of 97.5% ZnO, 1% Bi 2 o 3 , 0.5%Sb 2 o 3 , 0.5%Co 2 o 3 , 0.3%MnO 2 , 0.2%Cr 2 o 3 Weigh, then add and (97.5%ZnO+1%Bi 2 o 3 +0.5%Sb 2 o 3 +0.5%Co 2 o 3 + 0.3%MnO 2 +0.2%Cr 2 o 3 ) mass ratio is 0.5%, 1.0%, 1.5%, 2.0% of B 2 o 3 . According to the conventional solid-phase synthesis method, batching, ball milling and mixing for 8 hours, drying, adding 8wt% PVA binder, molding, plastic discharge (550°C, 1h), sintering at 870°C for 2h, the pressure-sensitive ceramics can be formed.

[0038] Table 2 below shows the electrical properties of the varistor ceramics obtained under this formulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com