Transducer compartment at the bottom of a ship

A transducer and ship bottom technology, which is applied in the shipbuilding industry, can solve the problems of increasing the total volume of the transducer cabin, the transducer arrangement is not compact enough, and the transducer cabin has no streamline shape, etc., and achieves compact structure and good flow diversion. effect, stable and accurate data collection and exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples.

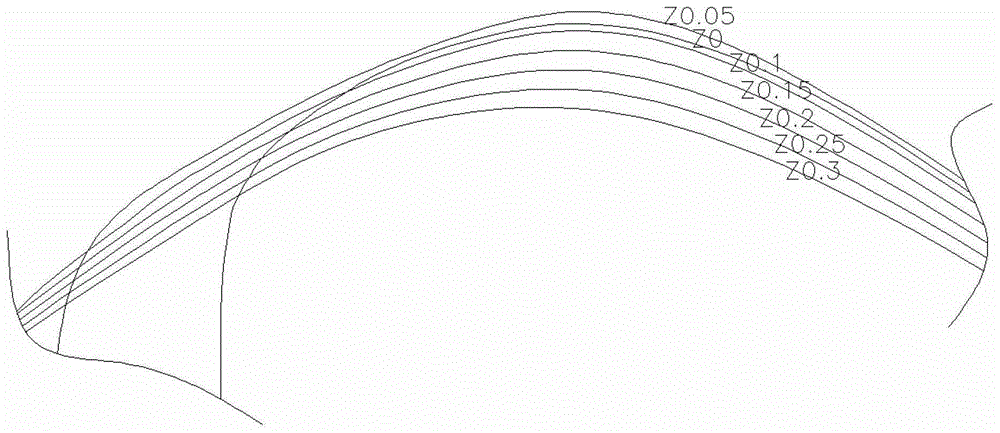

[0030] see Figure 1-Figure 7 , a transducer cabin at the bottom of a ship. At least two kinds of transducers can be placed in the transducer cabin 1. The transducer cabin 1 is a flat block-shaped shell structure with a smooth side surface, and a pair of mutually perpendicular The placement position of the long, strip-shaped transducer, the length direction of the transducer cabin 1 through the center is set as the X direction, the width direction is set as the Y direction, and the transducer cabin 1 is set close to the vertical direction of the bottom of the ship. is the Z direction; the transducer cabin 1 is divided into a left half and a right half, and the respective front and rear sides of the left and right half are symmetrical to each other; the planes of the transducer cabin 1 perpendicular to the Z axis are defined as water planes , each plane perpendicular to the X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com