Automatic pipe inserting device

A technology of automatic threading and driving device, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of slow threading speed and high labor intensity, and achieve short assembly time, reduce labor intensity of workers, and facilitate assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

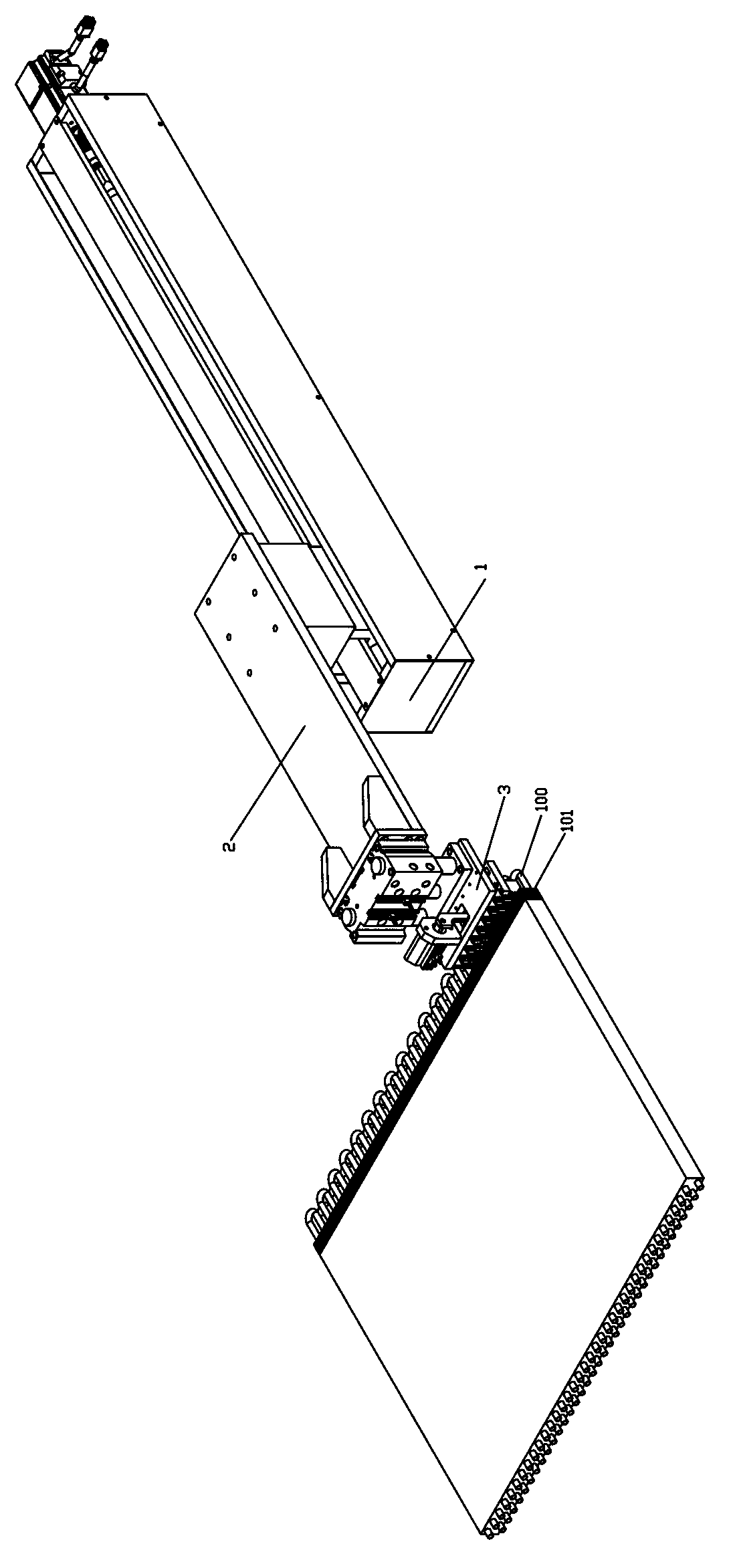

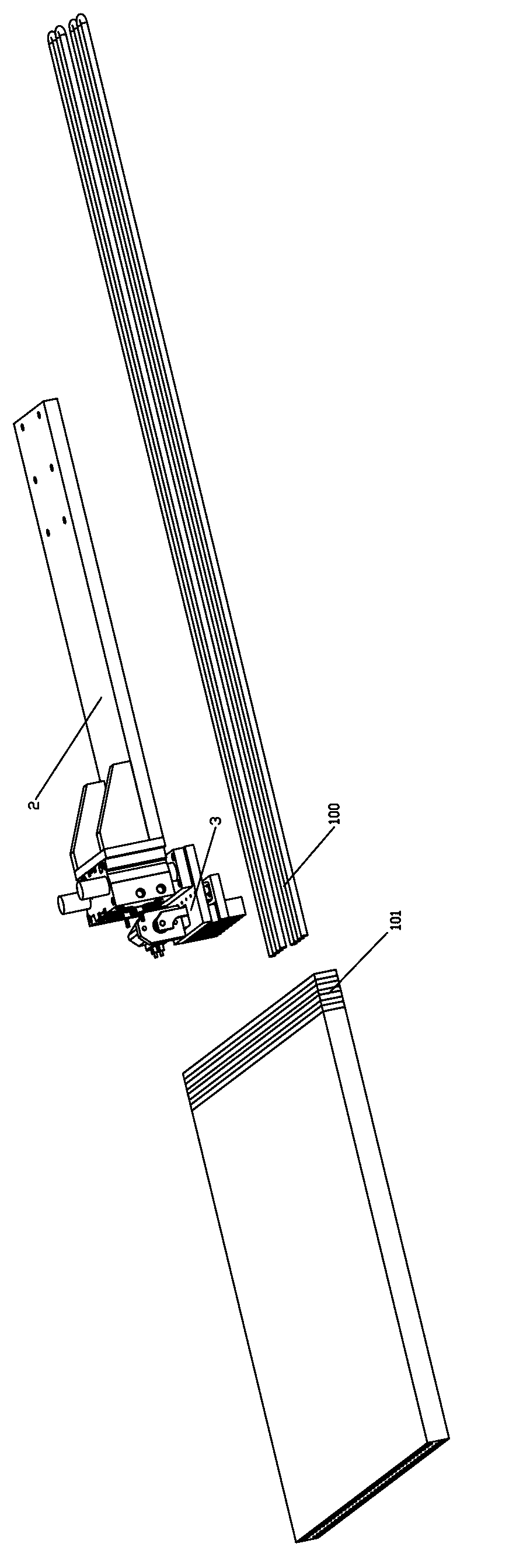

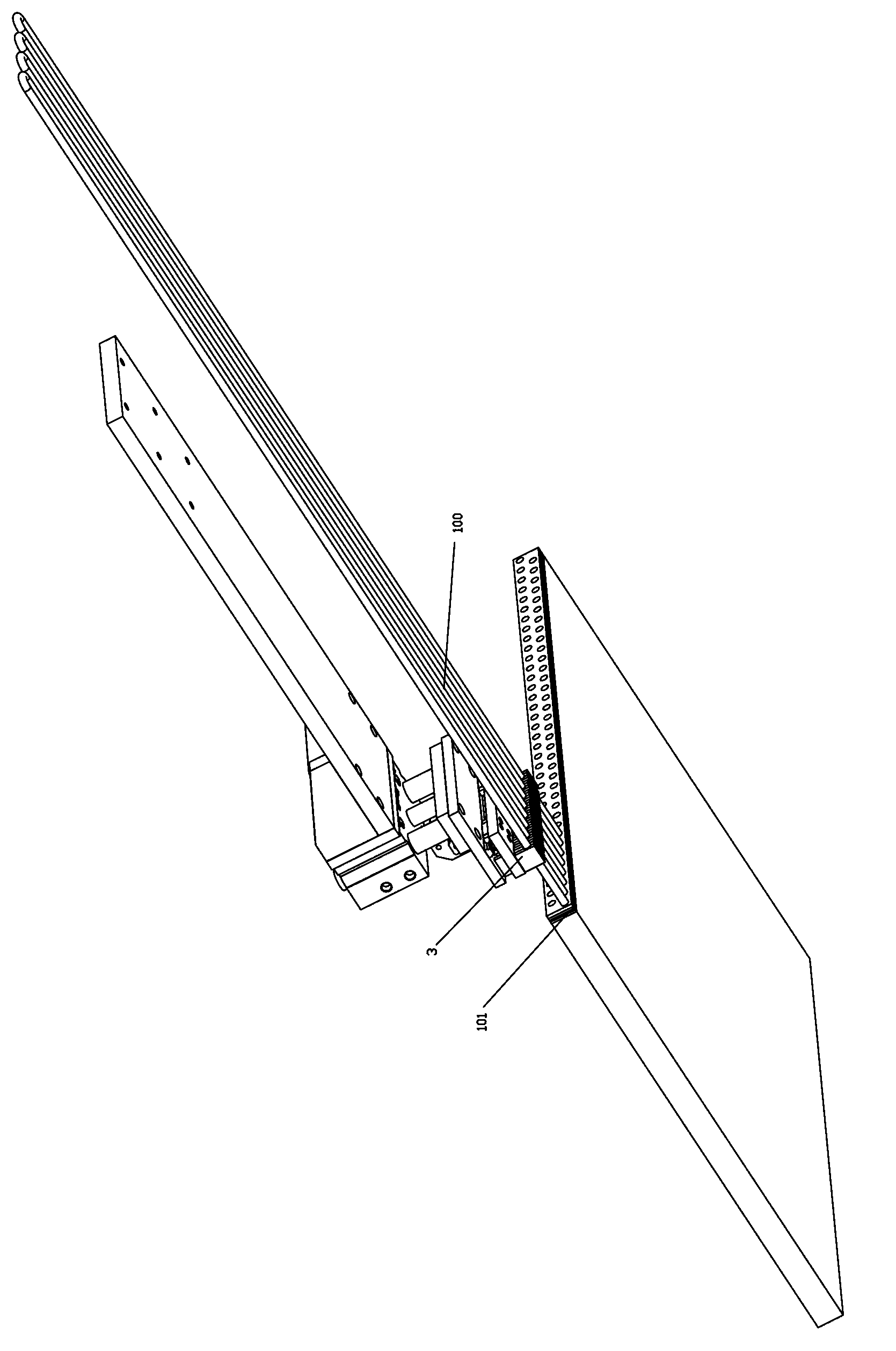

[0019] Such as figure 1 As shown, an automatic pipe threading device for inserting copper pipes into the fins in the condenser, which includes a fixed base 1, on which a feeding mechanism 2 that can move on the fixed base 1 is provided, and the feeding mechanism 2 is provided with a clamping mechanism 3 for clamping the U-shaped copper pipe 100. The clamping mechanism 3 includes a fixed base plate 31 connected to the feeder mechanism 2. The lower end of the fixed base plate 31 is provided with a plurality of fixed clips 32. The clip 32 is provided with a first semicircular groove 321 for fixing the U-shaped copper pipe 100, and the fixed substrate 31 is also provided with a driving device 33, the driving device 33 can be a cylinder, a motor, etc., and the output end of the driving device 33 Connected with a connecting piece 34 that can move on the fixed base plate 31, the connecting piece 34 is provided with a plurality of movable clips 35 that are interlaced with the fixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com