Hypoid gear rotary forging processing device and method for processing hypoid gear

A hypoid gear and processing device technology, which is applied in the field of mechanical processing, can solve the problems of not being suitable for processing hypoid gears, etc., and achieve the effect of small driving force, small impact, and guaranteed processing accuracy and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

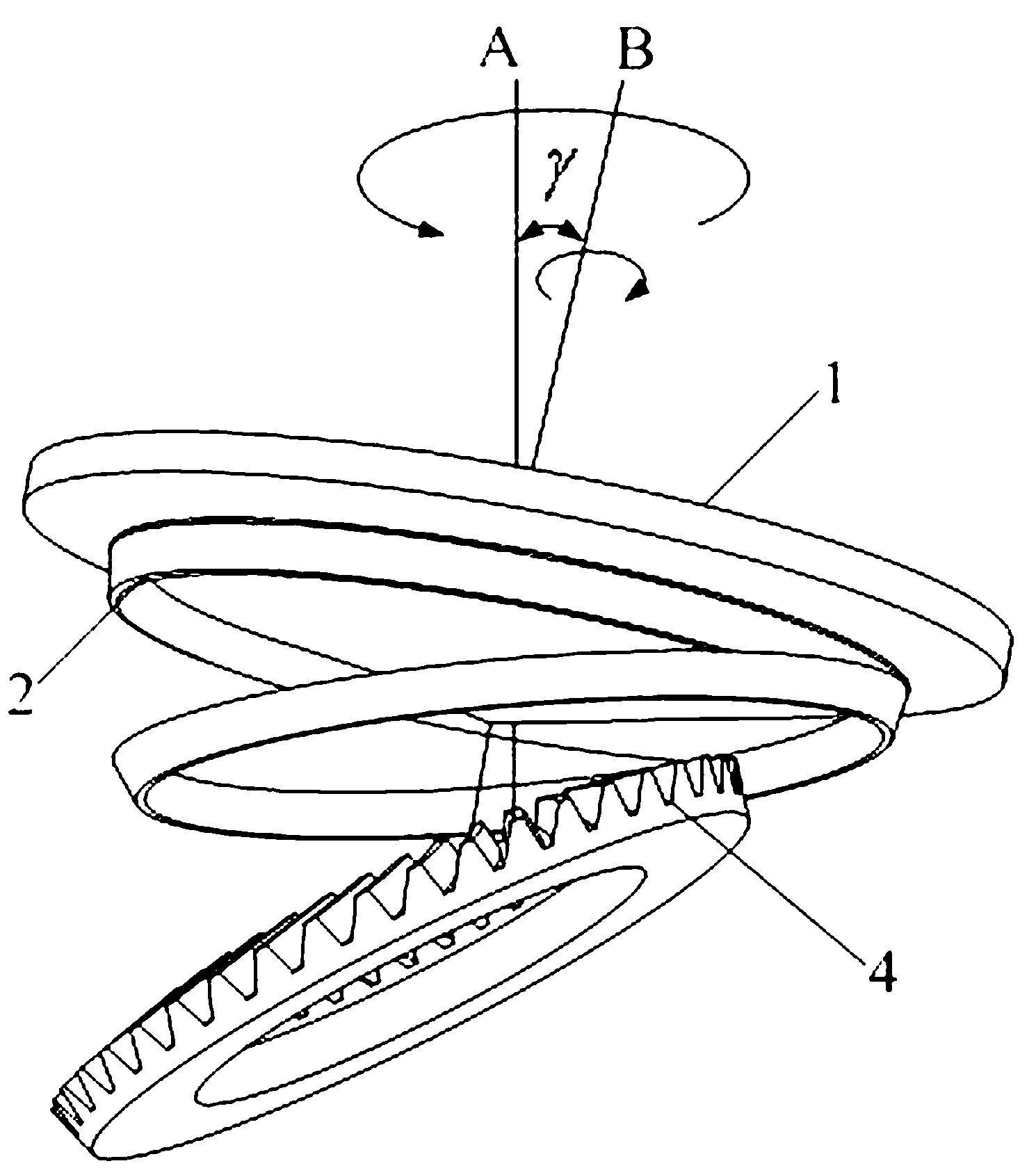

[0019] An embodiment of the hypoid gear rotary rolling processing device in the present invention is as follows Figure 1 ~ Figure 2 Shown, it is described in detail below in conjunction with accompanying drawing:

[0020] The rotary head 1 is clamped on the main shaft of the machine tool. The rotary head is conical, and the tooth-shaped mold 2 is embedded on the rotary head 1. The shapes of the rotary head 1 and the tooth-shaped mold 2 are as follows: figure 2 As shown, the tooth-shaped mold 2 is a ring-shaped rotary body formed by a trapezoidal cross-section that matches the tooth shape of the gear to be processed and rotates around the rotation axis of the oscillating head. The oscillating head drives the toothed mold on it to revolve around the axis of the machine tool spindle. Swing and rotate around its own axis. The angle γ between the axis of the conical oscillating head and the A-axis of the machine tool spindle is 7 degrees. A rotary table with a tiltable axis is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com