Method and equipment for carrying out detoxification treatment on chromium residue polluted soil

A technology for polluted soil and chromium slag is applied in the field of detoxification treatment of chromium slag polluted soil, and can solve the problems of low degree of mechanization, low efficiency and cumbersomeness of the detoxification process of chromium slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

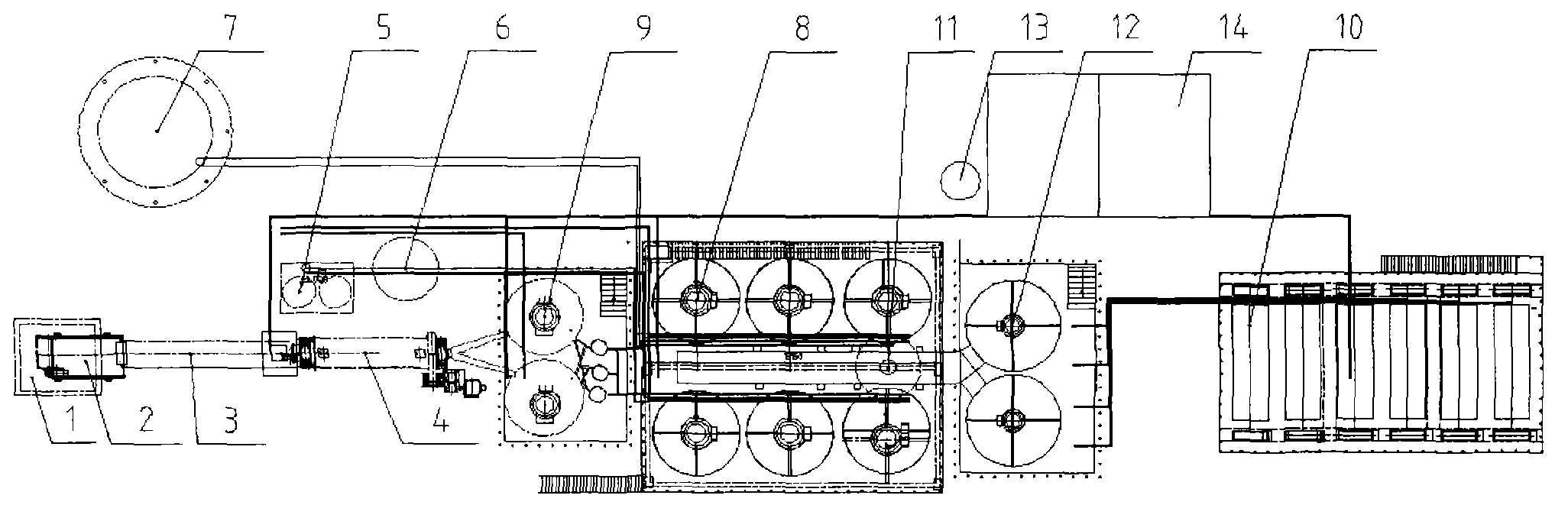

Image

Examples

Embodiment 1

[0031] The method for detoxification treatment of chromium slag contaminated soil consists of the following steps:

[0032] a. Grinding the soil containing chromium slag to 200 mesh, and mixing the obtained powder with water to make a slurry;

[0033] B, add the concentrated sulfuric acid that content is 32% and the sodium sulfide that content is 18% in slurry, make the water-soluble hexavalent chromium in it and acid-soluble hexavalent chromium dissolve and form solution;

[0034] c, add 22% ferrous sulfate in the solution as antidote, the reaction time is 8h, the temperature of reaction is 86 ℃, the pH value of controlling its reaction is 6, the hexavalent chromium in the solution is converted into trivalent chromium Solidify in the detoxified chromium slag, and solidify the detoxified soil.

Embodiment 2

[0036] The method for detoxification treatment of chromium slag contaminated soil consists of the following steps:

[0037] a. Grinding the soil containing chromium slag to 180 mesh, and mixing the obtained powder with water to make a slurry;

[0038] B, adding content is the concentrated sulfuric acid of 25% and the sodium sulfide of 20% in slurry, makes the water-soluble hexavalent chromium in it and acid-soluble hexavalent chromium dissolve to form a solution;

[0039] c, adding ferrous sulfate with a content of 16% in the solution as an antidote, the reaction time is 5h, the temperature of the reaction is 74°C, and the pH value of the reaction is controlled to be 5 so that the hexavalent chromium in the solution is converted into trivalent Chromium solidifies in the detoxified chromium slag and solidifies the detoxified soil.

Embodiment 3

[0041] The method for detoxification treatment of chromium slag contaminated soil consists of the following steps:

[0042] a. Grinding the soil containing chromium slag to 220 mesh, and mixing the obtained powder with water to make a slurry;

[0043] B, adding content is the concentrated sulfuric acid of 35% and the sodium sulfide of 15% in slurry, makes the water-soluble hexavalent chromium in it and acid-soluble hexavalent chromium dissolve to form a solution;

[0044] c, add content in the solution and be 24% ferrous sulfate as antidote, the time of reaction is 12h, and the temperature of reaction is 92 ℃, and the pH value of control its reaction is 6.5, and the hexavalent chromium in the solution is converted into three The valent chromium is solidified in the detoxified chromium slag, and the detoxified soil is solidified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com