Combined modular circulating water cultivating system

A circulating aquaculture, modular technology, applied in fish farming, application, animal husbandry, etc., can solve problems such as difficult maintenance, high operating costs, and complicated pipeline connections, and achieve the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

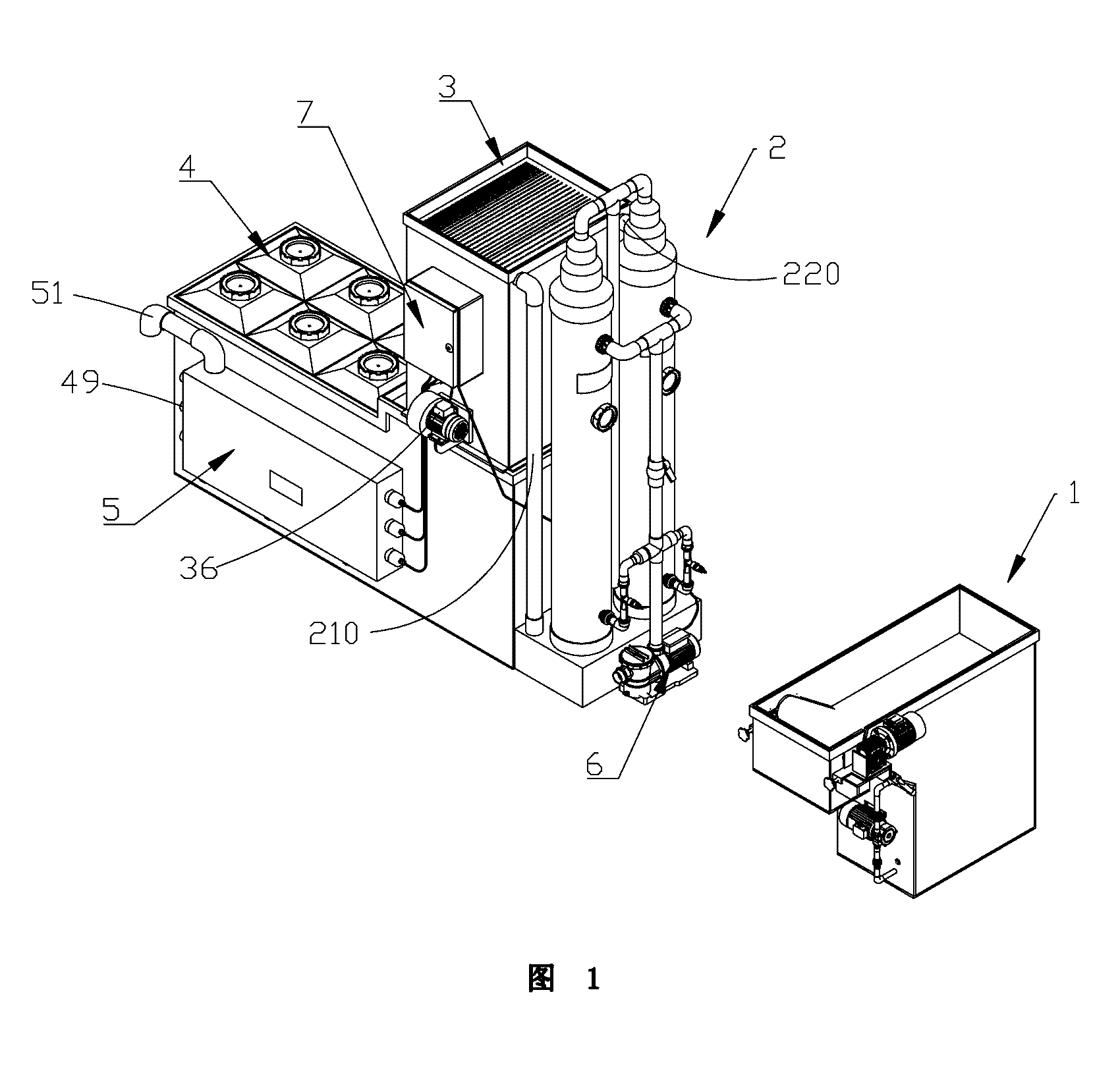

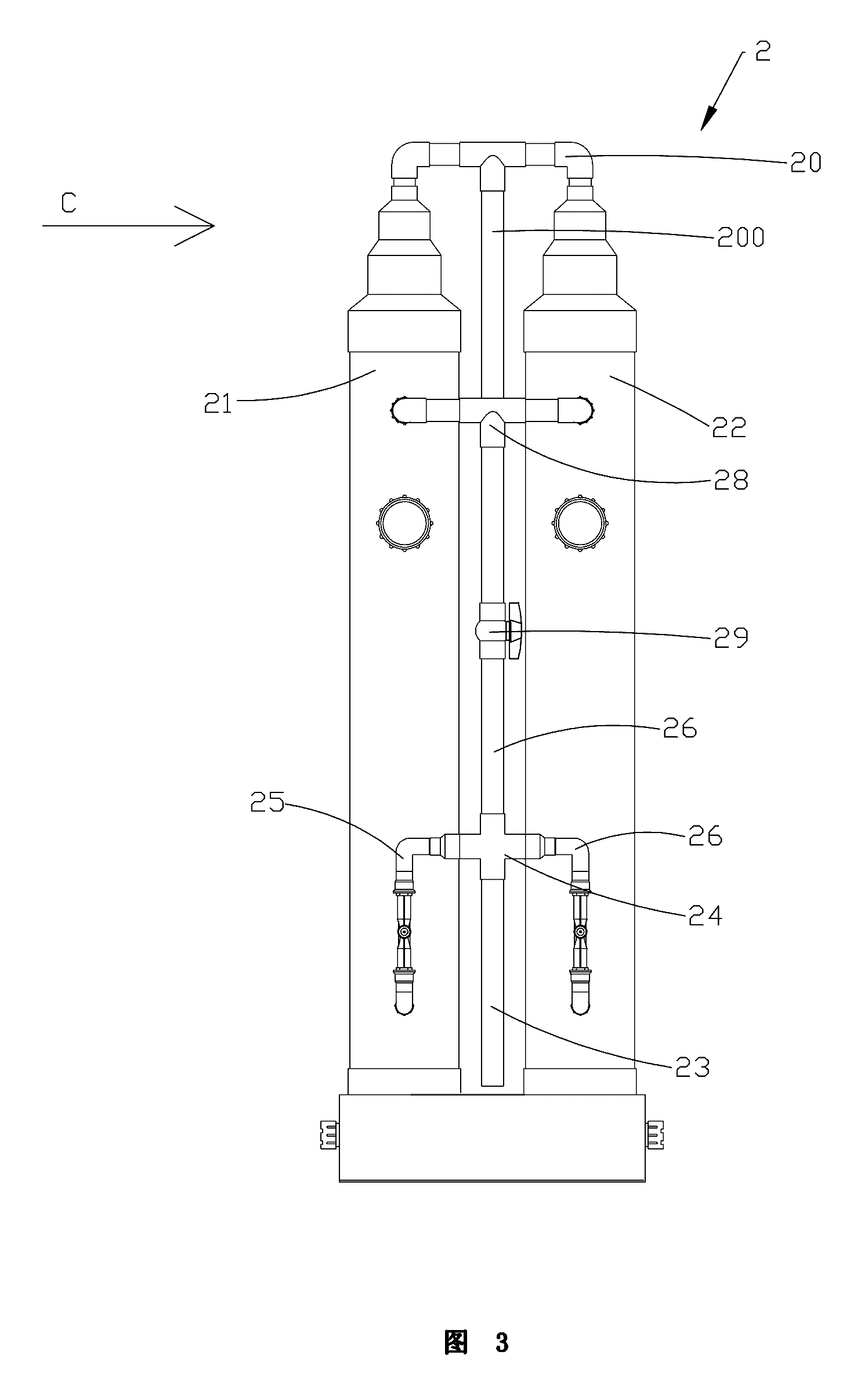

[0029] refer to figure 1 , a combined modular circulating aquaculture system, including a belt mechanical filter 1, a protein separator 2 connected to the belt mechanical filter 1, a drip box 3 connected to the protein separator 2, and a trickle box The biological filter bed 4 connected to 3, the ultraviolet disinfection machine 5 connected with the biological filter bed 4, the belt mechanical filter 1 pumps water into the protein separator 2 through the water pump 6, and the trickle box 3 is arranged at the bottom of the biological filter bed 4 Above, the highest water level of the protein separator 2 is higher than the highest water level of the drip box 3, and the highest water level of the biological filter bed 4 is higher than the highest water level of the ultraviolet sterilizer 5; also includes a central electronic controller 7, an ultraviolet ster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com