LED display screen display unit and automatic production method thereof

A technology of LED display screen and display unit, applied in the field of display screen, can solve the problems of inability to have high transmittance, and LED lamps cannot be automated patch circuit boards, etc., and achieve the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

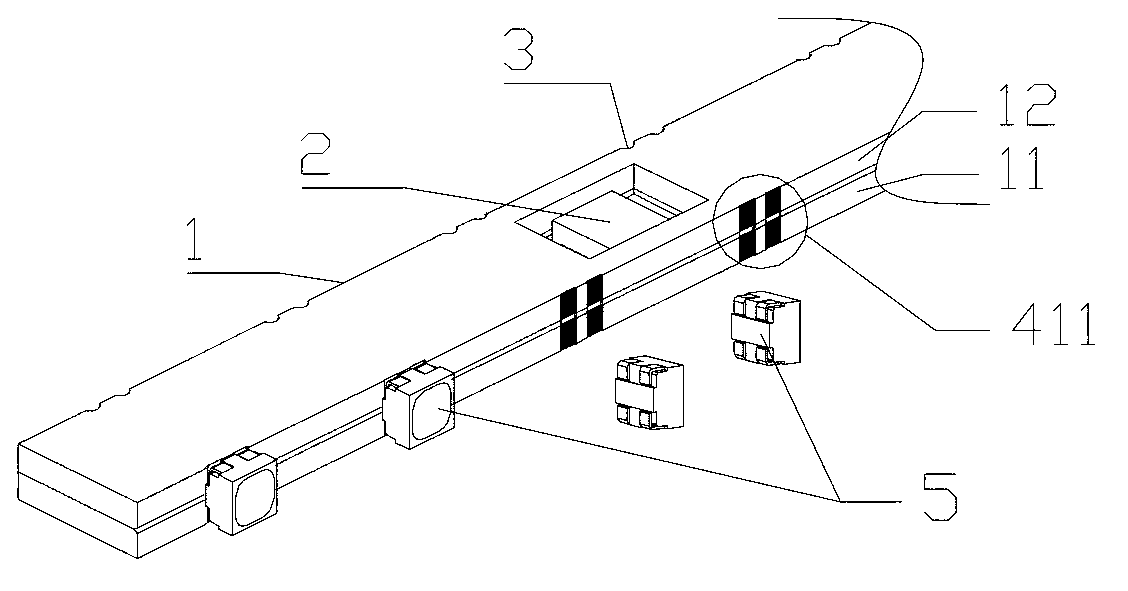

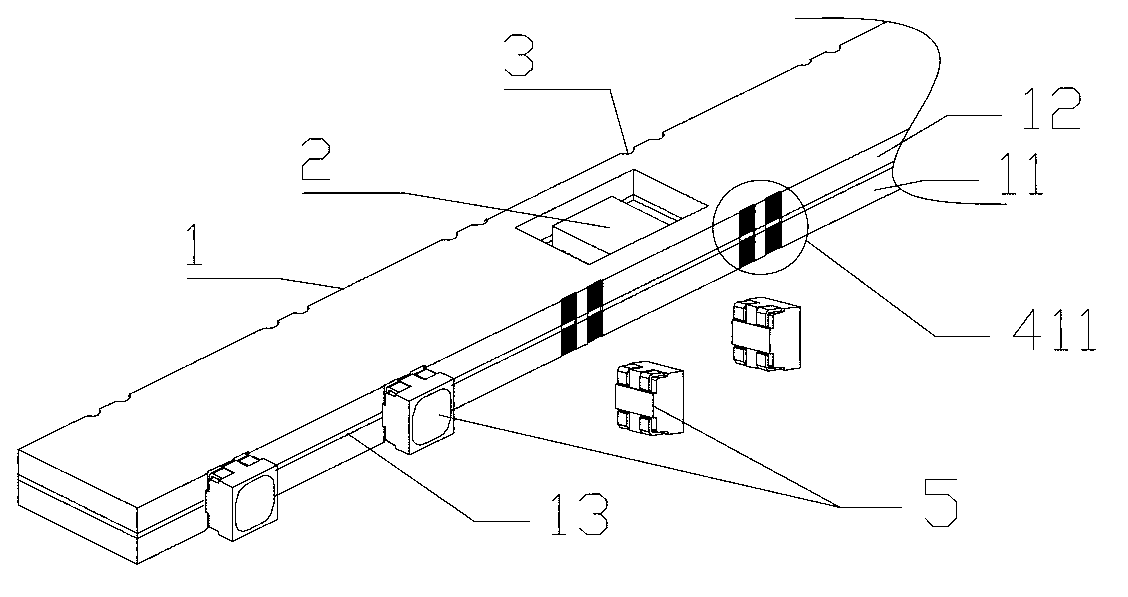

[0061] The first embodiment of an LED display unit of the present invention is figure 1 with figure 2 Shown:

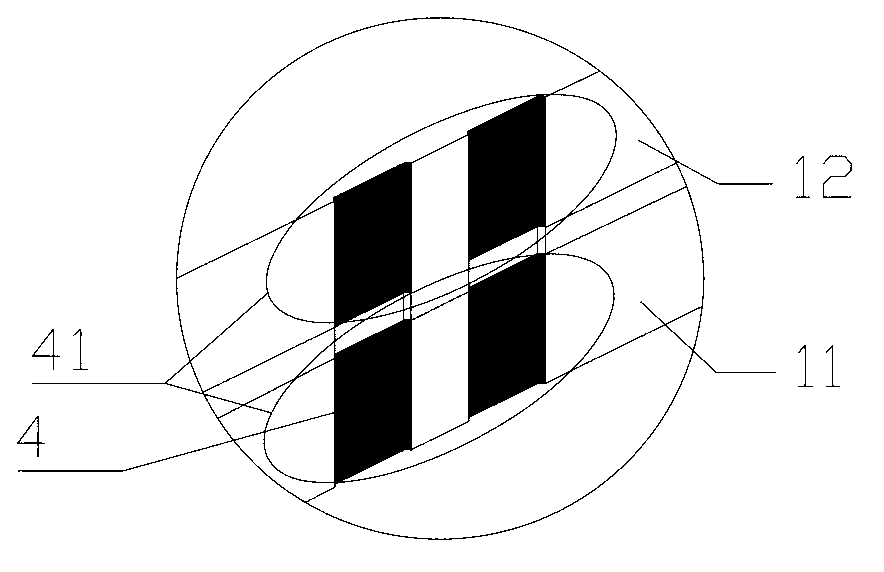

[0062] A kind of LED display screen display unit, comprises display unit main board 1, drive IC2, LED lamp 5, and described display unit main board 1 comprises the first circuit board 11, the second circuit board 12 of setting, the first circuit board 11 of the first The side and the first side of the second circuit board 12 are respectively provided with a pad group 41 composed of a plurality of pads 4, the pad group 41 of the first circuit board 11 and the pad group 41 of the second circuit board 12 are one by one. Corresponding and isolated from each other, a pad group 41 of the first circuit board 11 and a corresponding pad group 41 of the second circuit board 12 form a pad matrix 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com