Method for synthesizing Zn doped with CdTe quantum dots in one step

A technology of quantum dots and quantum dot solutions, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of unsuitability for large-scale production, easy oxidation of Te precursors, and long time required for quantum dots, so as to reduce the content of quantum dots. , Excellent optical properties, the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

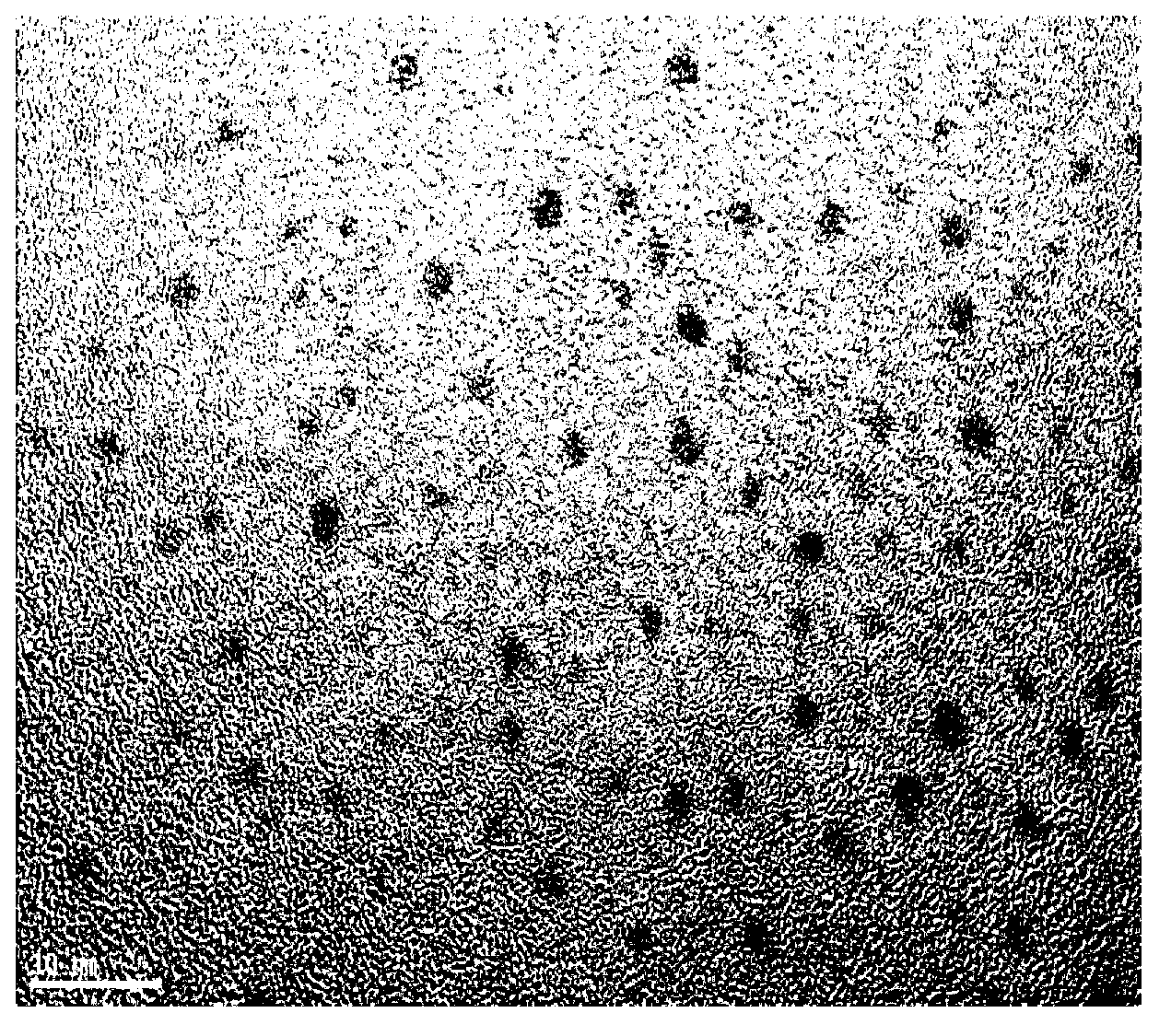

[0030] A method for synthesizing Zn-doped CdTe quantum dots in one step, the steps are as follows:

[0031] 1. Add 57mg CdCl 2 , 34mg ZnCl 2 and 83mg of thioglycolic acid were added to a three-necked flask, then 40mL of ultrapure water was added, and the pH was adjusted to 8.5 with 1mol / L NaOH solution, and then 6mg of NaOH was added 2 TeO 3 and 2 mg NaBH 4 , stirred and mixed, transferred to a hydrothermal reaction kettle, and then put the hydrothermal reaction kettle into an oven with a temperature set at 200 ° C for 45 minutes to obtain a Zn-doped CdTe quantum dot solution;

[0032] 2. Add isopropanol 3 times its volume to the quantum dot solution obtained in step 1 for precipitation, and centrifuge to separate the supernatant to obtain a solid precipitate;

[0033] After dissolving the obtained solid precipitate with distilled water, add 3 times its volume of isopropanol to the obtained quantum dot solution for precipitation, and the obtained solid precipitate is treat...

Embodiment 2

[0035] A method for synthesizing Zn-doped CdTe quantum dots in one step, the steps are as follows:

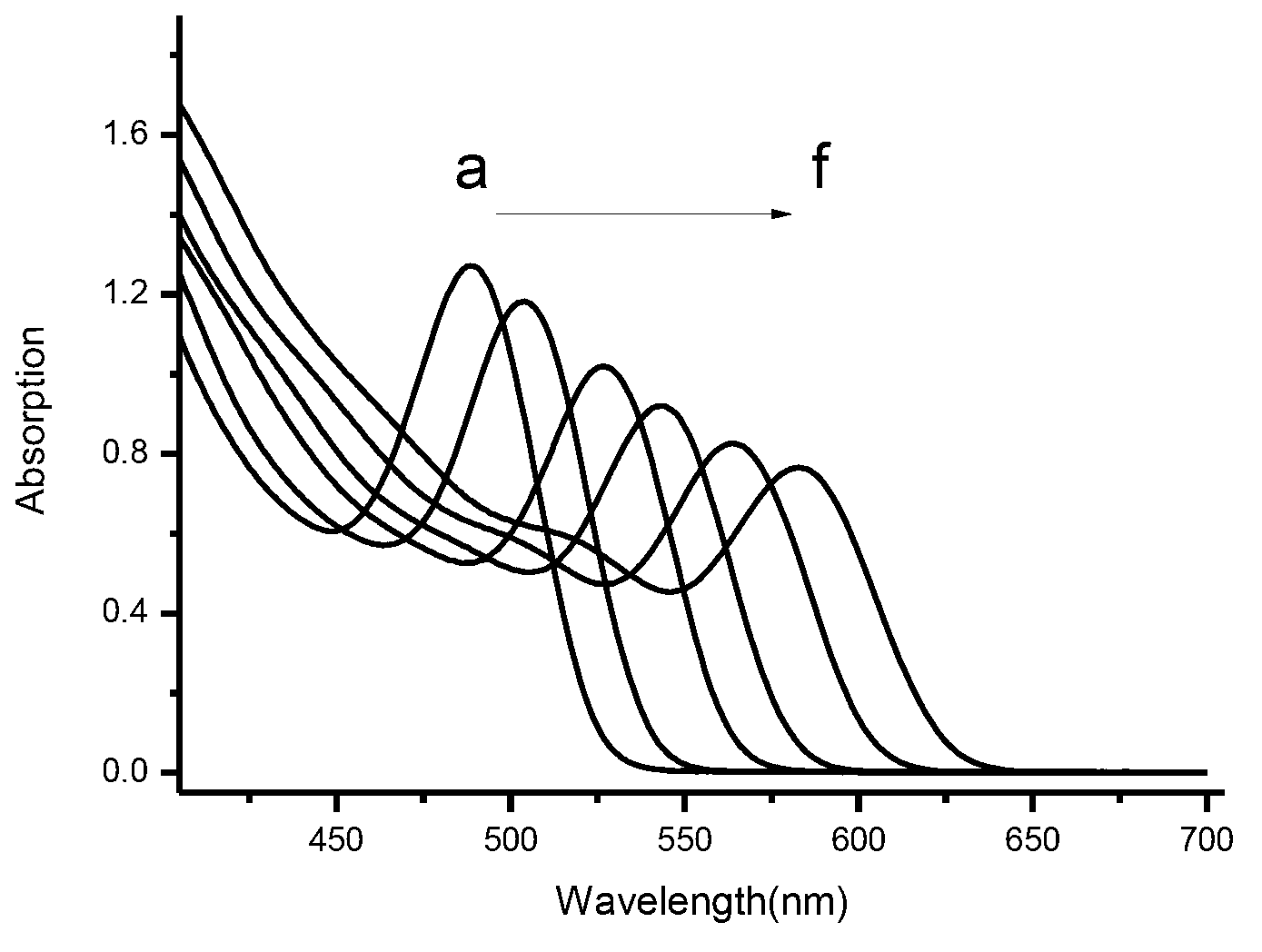

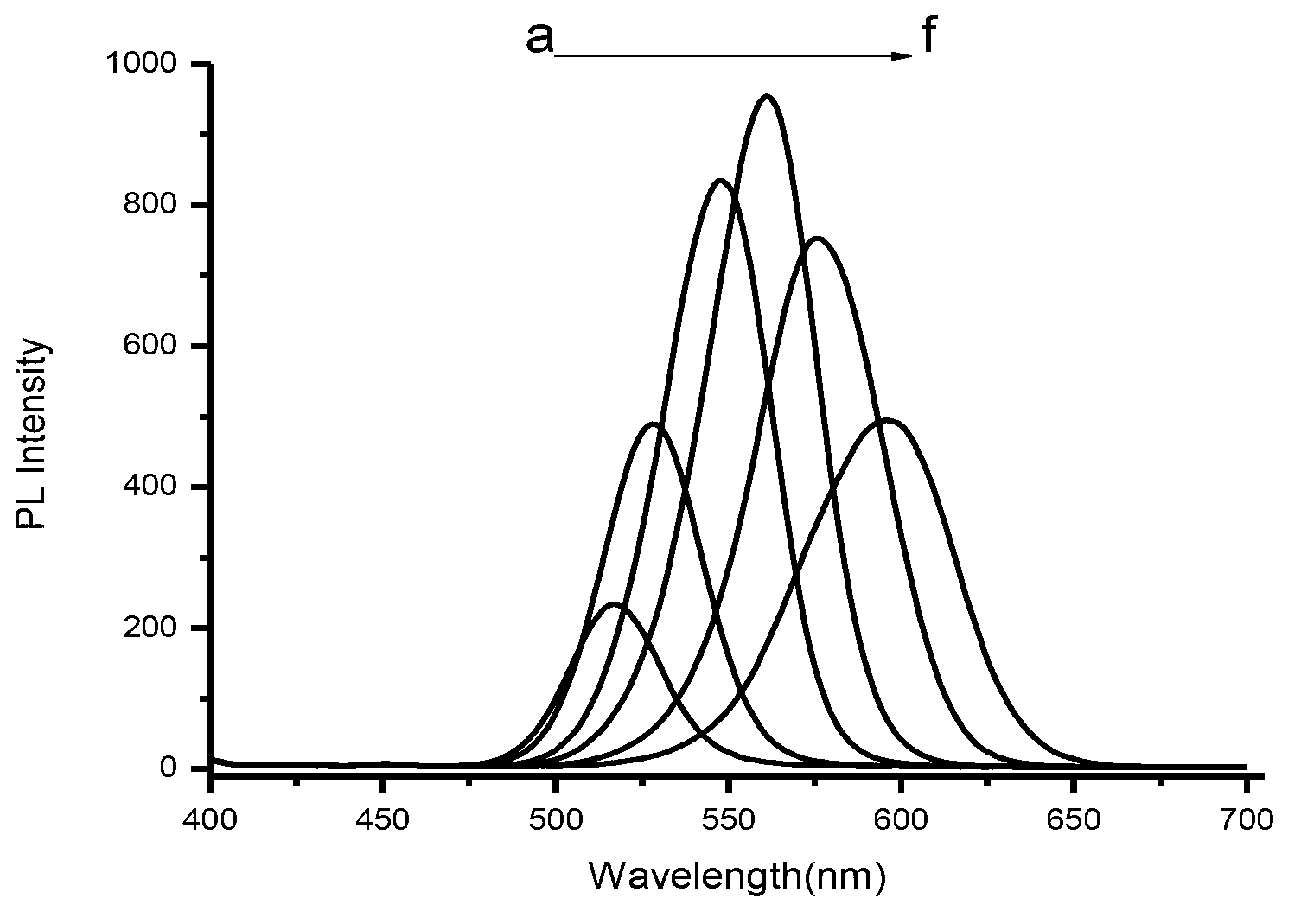

[0036] 1. Add 57mgCdCl 2 , 34mg ZnCl 2 and 147mg of N-acetyl-L-cysteine were added to a three-necked flask, then 40mL of ultrapure water was added, the pH was adjusted to 8.0 with 1mol / L NaOH solution, and then 11mg of NaOH was added 2 TeO 3 and 5mg NaBH 4 , stirred and mixed, transferred to a hydrothermal reaction kettle, and then put the hydrothermal reaction kettle into an oven with a temperature set at 200 ° C for 31 minutes to obtain a Zn-doped CdTe quantum dot solution a;

[0037] The rest of the conditions are the same, only the reaction time is changed to 36min, then the quantum dot solution b is obtained;

[0038] The rest of the conditions are the same, only the reaction time is changed to 41min, then the quantum dot solution c is obtained;

[0039] The rest of the conditions are the same, only the reaction time is changed to 45min, then the quantum dot solution ...

Embodiment 3

[0044] A method for synthesizing Zn-doped CdTe quantum dots in one step, the steps are as follows:

[0045] 1. Add 57mg CdCl 2 , 68mg ZnCl 2 and 147mg of N-acetyl-L-cysteine were added to a three-necked flask, then 40mL of ultrapure water was added, the pH was adjusted to 9.0 with 1mol / L NaOH solution, and then 17mg of K 2 TeO 3 and 7mg KBH 4 , stirred and mixed, transferred to a hydrothermal reaction kettle, and then put the hydrothermal reaction kettle into an oven with a temperature set at 200 ° C for 45 minutes to obtain a Zn-doped CdTe quantum dot solution;

[0046] 2. The subsequent processing method of the quantum dot solution obtained in step 1 is the same as that in Example 1. Finally, dry solid Zn-doped CdTe quantum dots are obtained, stored at 4° C., and reconfigured into an aqueous solution of the required concentration when used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com