Explosive cladding explosive and preparation method and applications thereof

An explosive composite board and explosive technology, which is applied in the directions of explosives, manufacturing tools, welding equipment, etc., can solve the problems in the field of low-performance explosive composites, affect the quality of explosive composites, and explosive agglomeration, and achieve high anti-caking performance. The effect of functional power and sturdiness, and strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

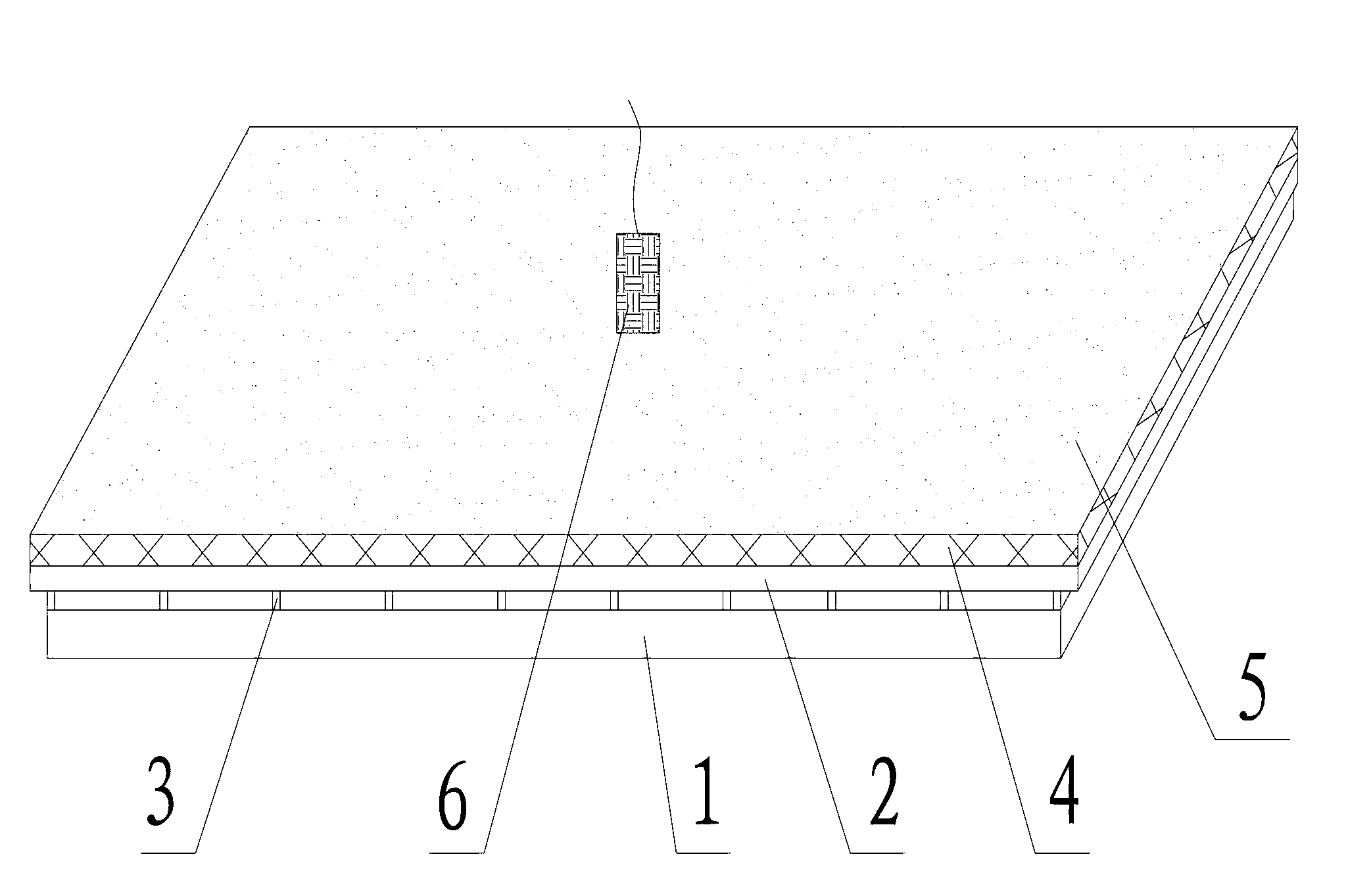

Image

Examples

Embodiment 1

[0028] The explosive composite explosive in this embodiment is made of the following mass percentages of raw materials: expanded ammonium nitrate explosive 68%, calcium nitrate 23%, graphite 7.5%, magnesium stearate 1.5%; the expanded ammonium nitrate explosive is rock expanded ammonium nitrate Explosive; the bulk density of the calcium nitrate is 1.1g / cm 3 , The mass purity is 98%, the average particle size is 0.1mm, and the mass percentage of water in calcium nitrate is 0.1%; the bulk density of the graphite is 0.5g / cm 3 , The average particle size is 0.1mm, and the mass percentage of water in the graphite is 1%; the bulk density of the magnesium stearate is 0.95g / cm 3 , The average particle size is 50 μm, and the mass percentage of magnesium oxide in the magnesium stearate is 7.0%; the rock expanded ammonium nitrate explosive, calcium nitrate, graphite and magnesium stearate are all commercially available commodities.

[0029] The preparation method of the explosive in this embo...

Embodiment 2

[0036] The explosive composite explosive in this embodiment is made of the following mass percentages of raw materials: 70% expanded ammonium nitrate explosive, 22% calcium nitrate, 6% graphite, and 2% magnesium stearate; the expanded ammonium nitrate explosive is rock expanded ammonium nitrate Explosive; the bulk density of the calcium nitrate is 1.2g / cm 3 , The mass purity is 95%, the average particle size is 0.1mm, and the mass percentage of water in calcium nitrate is 0.2%; the bulk density of the graphite is 0.6g / cm 3 , The average particle size is 0.1mm, and the mass percentage of water in the graphite is 5%; the bulk density of the magnesium stearate is 1g / cm 3 , The average particle size is 35 μm, and the mass percentage of magnesium oxide in the magnesium stearate is 7.5%; the expanded ammonium nitrate explosive, calcium nitrate, graphite and magnesium stearate are all commercially available products.

[0037] The preparation method of the explosive in this embodiment is a...

Embodiment 3

[0044] The explosive composite explosive in this embodiment is made of the following mass percentages of raw materials: expanded ammonium nitrate explosive 69%, calcium nitrate 24%, graphite 5%, magnesium stearate 2%; the expanded ammonium nitrate explosive is rock expanded ammonium nitrate Explosive; the bulk density of the calcium nitrate is 1.2g / cm 3 , The mass purity is 99%, the average particle size is 0.1mm, and the mass percentage of water in calcium nitrate is 0.4%; the bulk density of the graphite is 0.6g / cm 3 , The average particle size is 0.1mm, and the mass percentage of water in the graphite is 5%; the bulk density of the magnesium stearate is 0.94g / cm 3 , The average particle size is 75 μm, and the mass percentage of magnesium oxide in the magnesium stearate is 7.0%; the expanded ammonium nitrate explosive, calcium nitrate, graphite and magnesium stearate are all commercially available products.

[0045] The preparation method of the explosive in this embodiment is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com