Gantry type hull sectional drawing machine

A technology of marking machine and gantry, which is applied to ship components, ship construction, ship design, etc., can solve the problems of wasting effective working time of cranes, occupying the cycle of berth or dock, and high risk of operation, so as to achieve ingenious device design and improve The level of manufacturing technology and the effect of simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

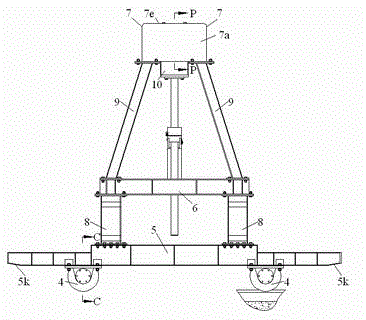

[0026] The structure of the present invention will be further described below with reference to the accompanying drawings.

[0027] Gantry hull section marking machine (such as figure 1 , 2 , Shown in 3) is made up of marking mechanism and gantry frame, and marking mechanism is installed on the upper beam 7 of gantry. The scribing mechanism mainly includes a trolley 10 and a multi-degree-of-freedom scribing arm. The gantry includes track 1 and track wheel 4, horizontal beams and column groups. The main function of the marking mechanism is to provide high-precision multi-degree-of-freedom movement and positioning; the main function of the gantry is to support the trolley and the marking arm, and carry control equipment.

[0028] 1. Tracks and wheels

[0029] The track 1 is laid horizontally and parallel, and is firmly connected with the ground concrete. The upper surface of the track 1 in the trench 2 is flush with the ground, which facilitates the segmental displacement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com