Recoiling machine reducer casing output shaft bearing hole abrasion repairing method

A wear repair and bearing hole technology, applied in the field of wear repair, can solve the problems of gear and bearing damage, unstable operation, large vibration of the output shaft of the reel 5, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

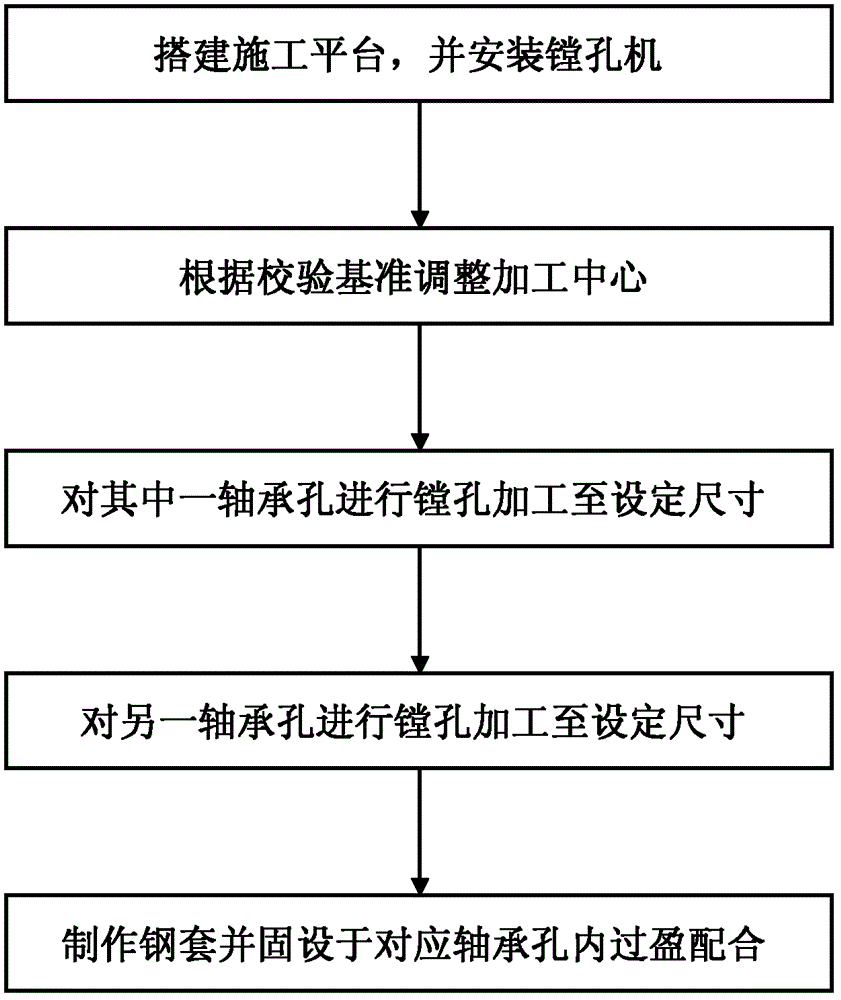

[0026] Please combine figure 2 , image 3 As shown, the method for repairing the wear and tear of the output shaft bearing hole of the coiler reduction box of the present invention mainly includes the following steps:

[0027] A. Build the construction platform and tooling support, and install the boring machine on the tooling support;

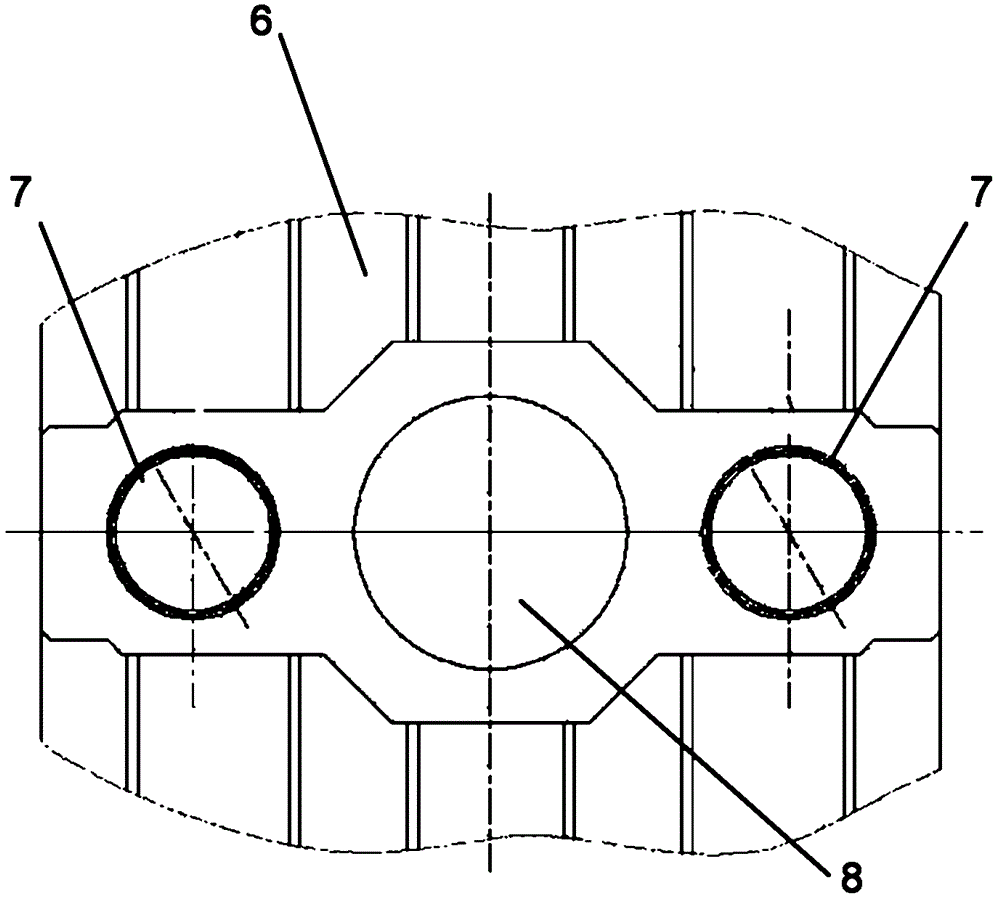

[0028] B. Taking the input shaft bearing hole 8 in the middle of the positioning side of the reduction box 6 as the calibration reference, adjust the machining center of the boring machine and the corresponding output shaft bearing hole 7 so that the runout is less than 0.03mm;

[0029] C. Boring the output shaft bearing hole 7 to the set size;

[0030] D. Boring the other output shaft bearing hole 7 to the set size in the same way as above;

[0031] E. Make a steel sleeve separately, mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com