Seam welder for steel reinforcement framework

A technology of steel skeleton and seam welding machine, which is applied in welding equipment, welding equipment, resistance welding equipment and other directions, can solve the problems of unreliable fixing of steel bars, poor safety performance, low work efficiency, etc., and achieves simple structure, high work efficiency, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

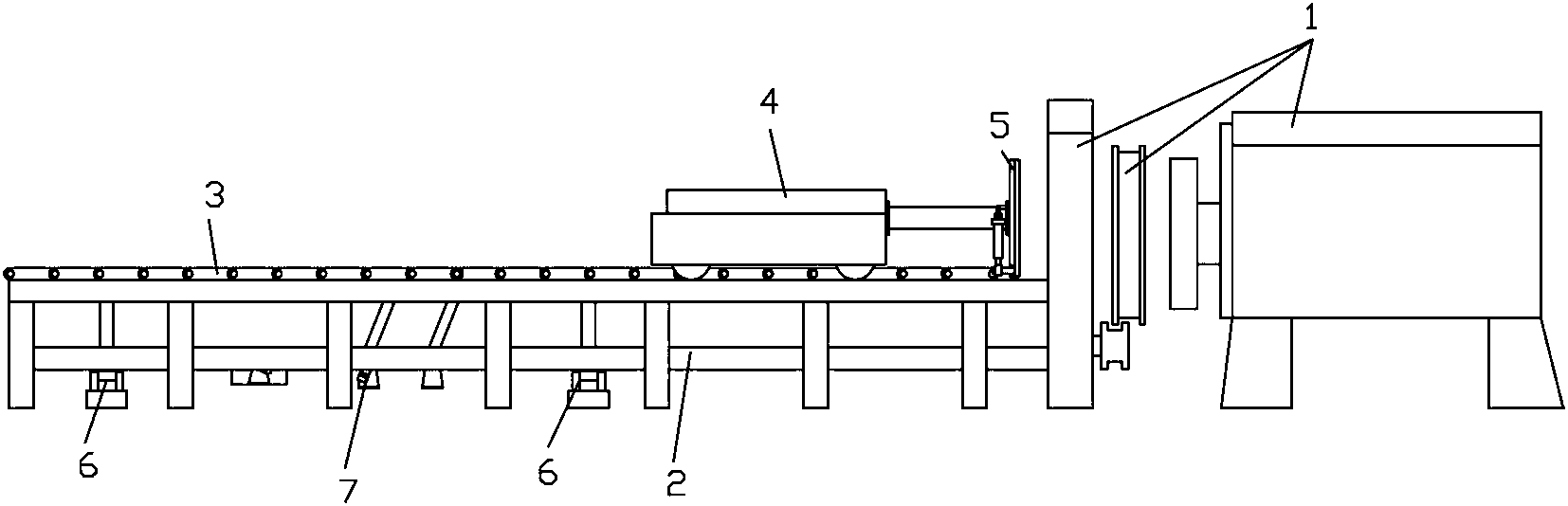

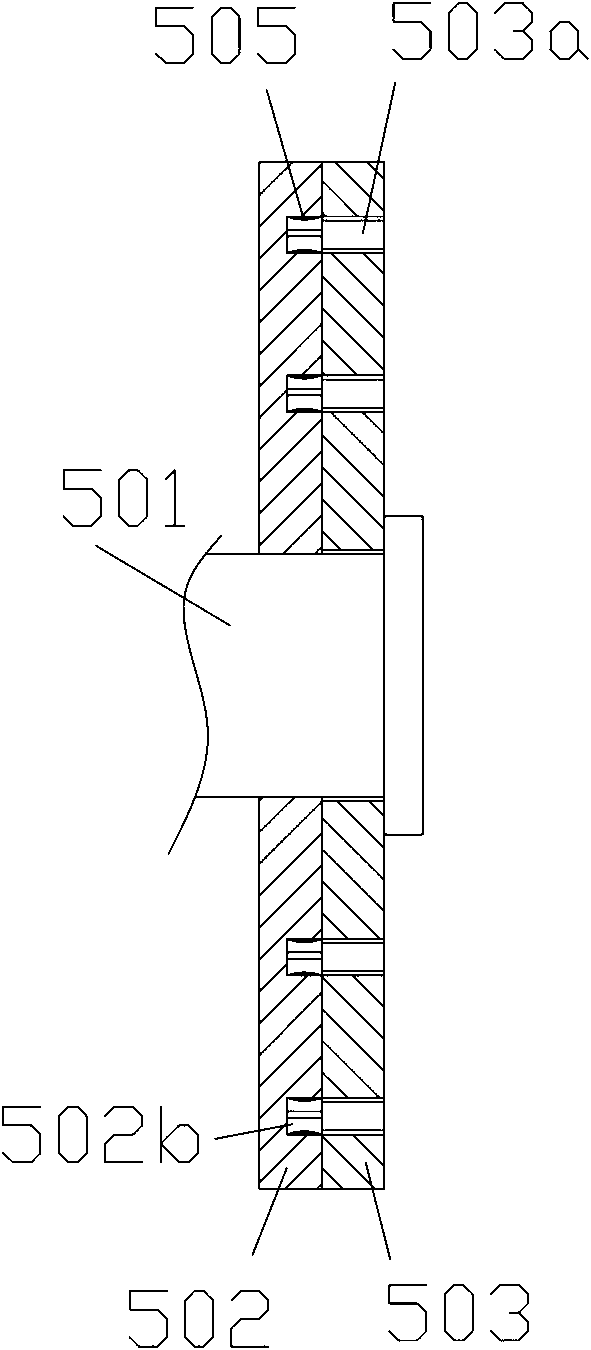

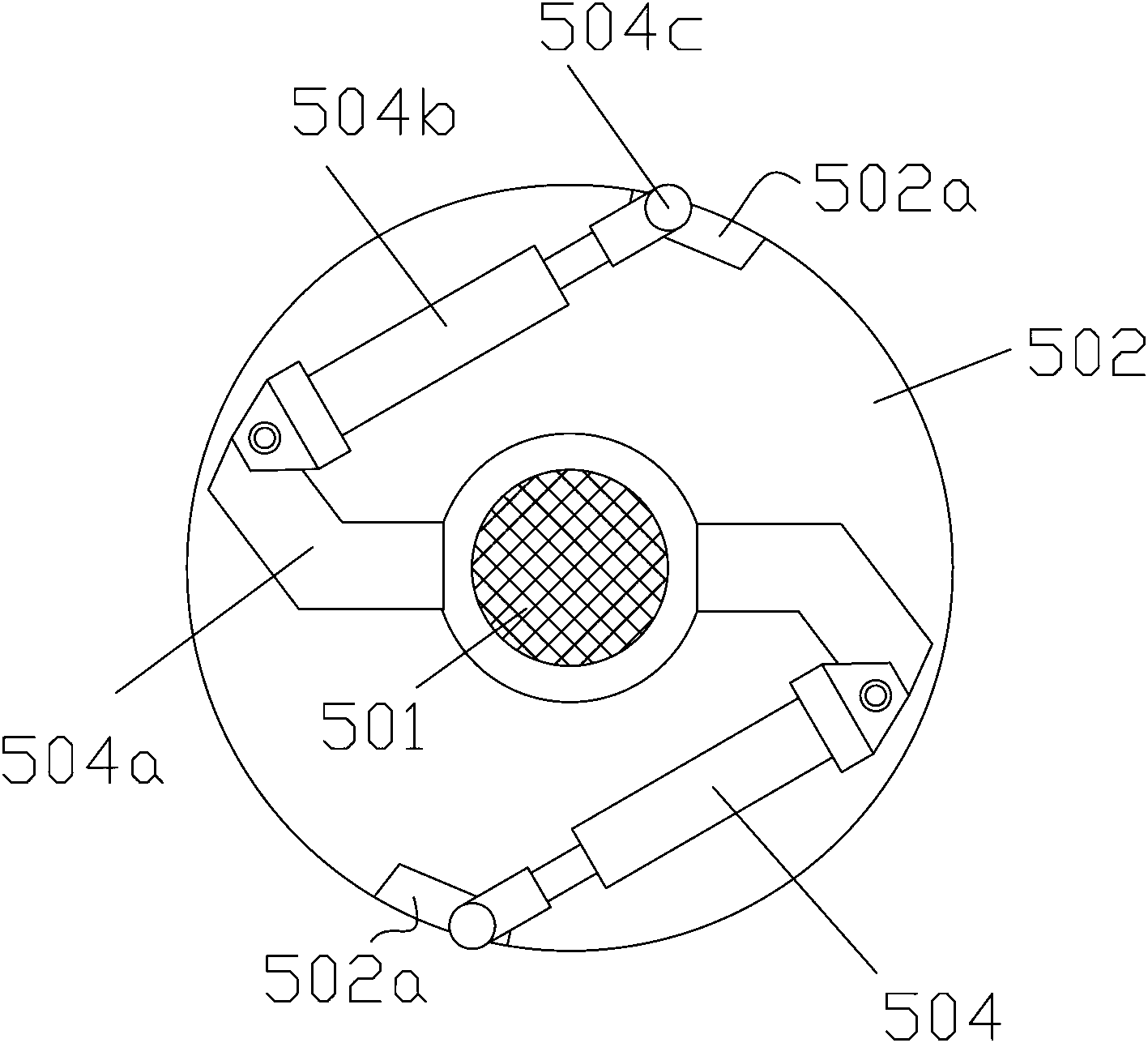

[0041] Examples, see attached figure 1 , 2 , 3, 4, 5, 6, steel frame seam welding machine, including seam welding device 1, seam welding device 1 includes welding device and wire drawing device, blanking platform 2, adopts steel pipe welding to form, is arranged on described blanking The conveyor chain 3 on the platform 2, the pulling device 4 arranged on the blanking platform 2 and the steel bar skeleton locking device 5 installed on the pulling device 4, the pulling device 4 is used for the The reinforcement frame locking device 5 includes a fixed shaft 501, a rear limiting plate 502 with a circular blind hole 502b fixed on the fixed shaft 501, a front limiting plate 503 sleeved on the fixed shaft 501, and a driving force. The rotating device 504 for the rotation of the front limiting plate 503, the fixed shaft 501 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com