Visible light photosensitization preparation method of TiO2-rGO compound light catalyst

A catalyst, composite light technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve good social and economic benefits, high visible light photocatalytic performance, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

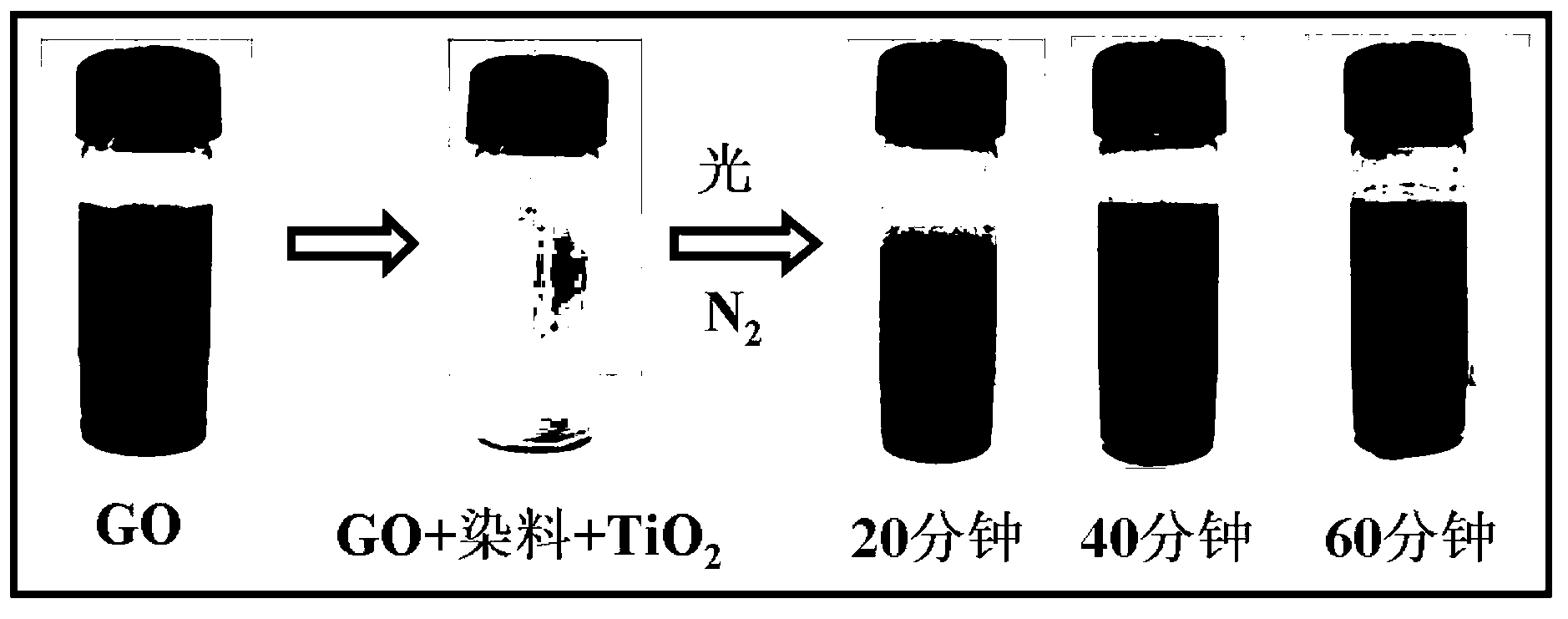

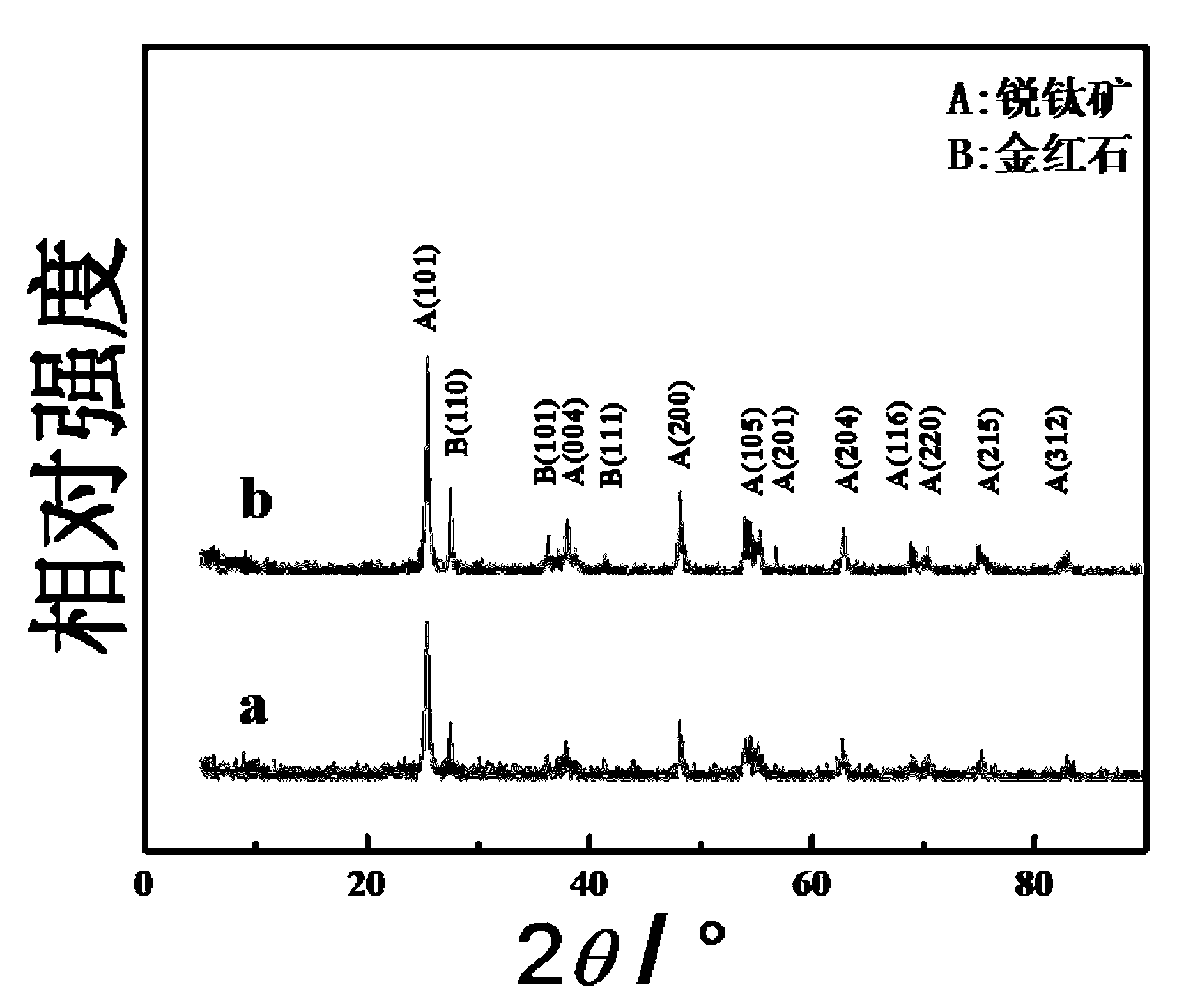

[0031] TiO 2 -rGO composite photocatalyst was prepared as follows: (1) 1 g of commercial P25 TiO 2 After heat treatment at 550°C for 2 h; (2) GO was ultrasonically dispersed and dissolved in deionized water to form a homogeneous solution, in which the concentration of GO was 0.05 wt%; (3) 2.5 mL of 10 mg / L rhodamine B solution was mixed with 10 mL of GO The solution is mixed evenly; (4) 1 g of heat-treated TiO 2 The nanoparticles were dispersed into the mixed solution of GO and rhodamine B obtained above, and stirred to form a uniform suspension; (5) the suspension prepared above was placed in N 2 Under protective gas, irradiate with visible light of 300 W xenon lamp for 60 min; (6) The obtained product was washed with deionized water for 3 times, and then dried at 60 °C for 6 h to obtain TiO 2 -rGO composite photocatalyst.

[0032] figure 1 Synthesis of TiO by Dye Photosensitization 2 Schematic diagram of the synthesis principle of the -rGO composite photocatalyst. Unde...

Embodiment 2

[0043] In order to test TiO 2 Effect of powder heat treatment temperature on TiO 2 - Influence of rGO composite photocatalyst, in addition to different heat treatment temperature, other reaction conditions such as: TiO 2 Powder heat treatment time (2 h), GO concentration (0.05 wt%), rhodamine B concentration (10 mg / L), light time (60 min), drying temperature (60 °C), drying time (6 h) were all related to Example 1 is the same. The results show that when the heat treatment temperature is 100 °C, TiO 2 The impurities adsorbed on the powder surface cannot be effectively removed, resulting in TiO 2 The powder and GO solution cannot form a homogeneous suspension, and the prepared TiO 2 The photocatalytic performance of -rGO composite photocatalyst is low (0.0065 min -1); when the heat treatment temperature is 350-600 ° C, TiO 2 Powder and GO solution can form a good uniform suspension, the prepared TiO 2 The photocatalytic performance of -rGO composite photocatalyst is 0.008...

Embodiment 3

[0045] In order to test TiO 2 Powder heat treatment time on TiO 2 - Influence of rGO composite photocatalyst, in addition to different heat treatment time, other reaction conditions such as: TiO 2 Powder heat treatment temperature (550°C), GO concentration (0.05 wt%), rhodamine B concentration (10 mg / L), light exposure time (60 min), drying temperature (60°C), drying time (6 h), etc. Example 1 is the same. The results show that when the heat treatment time is 0.5 h, TiO 2 The impurities adsorbed on the powder surface could not be effectively removed, resulting in TiO 2 The powder and the GO solution cannot form a homogeneous suspension, and the prepared TiO 2 The photocatalytic performance of the -rGO composite photocatalyst was not significantly improved (0.0067 min -1 ); when the heat treatment time is 1 and 3 h, TiO 2 Powder and GO solution can form a good uniform suspension, the prepared TiO 2 The photocatalytic performances of -rGO composite photocatalysts are 0.00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com