Preparation method for cellulose ether-sodium alginate-tetraethylortho silicate pervaporation and hybrid membrane

A technology of tetraethyl orthosilicate and pervaporation, applied in chemical instruments and methods, semipermeable membrane separation, membrane technology, etc., can solve the problem of low pervaporation membrane separation factor, insufficient permeation flux, and complicated membrane preparation process and other problems, to achieve the effects of good controllability and production repeatability, uniform appearance, excellent solvent resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

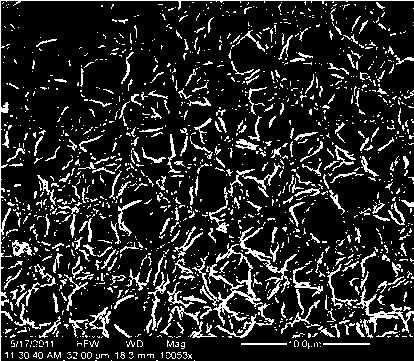

Image

Examples

Embodiment 1

[0029] Example 1: Weigh 4g of hydroxyethyl cellulose and dissolve it in 100g of distilled water, stir at 70°C until it is completely dissolved, weigh 2g of sodium alginate and add it to the hydroxyethyl cellulose solution, and continue stirring for 12 hours until a homogeneous solution is formed. phase transparent solution. Then weigh 0.2g (5wt%, relative to HEC) TEOS, dissolve it in water to make it hydrolyzed, the molar ratio of water to TEOS is 5:1, adjust the pH of the solution to 1-3 with hydrochloric acid, wait for the TEOS aqueous solution to react to After clarification, slowly add into the hydroxyethyl cellulose-sodium alginate aqueous solution, and keep stirring to form a homogeneous transparent sol. Filter the obtained sol through a 2# sand core funnel to remove insoluble matter, let it stand still, and defoam to obtain a casting solution. Coat the sol on the surface of the polyacrylonitrile base film with a doctor blade, gel and dry at room temperature for 48 hou...

Embodiment 2

[0030] Embodiment 2: The process steps as in Example 1, wherein only the amount of TEOS added is changed to 0.4g (10wt%, relative to HEC), and the hydroxyethyl cellulose-sodium alginate organic-inorganic hybrid of the present invention is made membrane. When the feed concentration (methanol wt%) is 90% and 95% respectively, the permeation flux J (g / m 2 h) are 395 and 325 respectively, and the separation factor α is 331 and 788 respectively.

Embodiment 3

[0031] Embodiment 3: The process steps as in Example 1, wherein only the amount of TEOS added is changed to 0.6g (15wt%, relative to HEC), and the hydroxyethyl cellulose-sodium alginate organic-inorganic hybrid membrane. When the feed concentration (methanol wt%) is 90% and 95% respectively, the permeation flux J (g / m 2 h) are 347 and 253 respectively, and the separation factor α is 638 and 1207 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com