Method for preparing leaching liquor of paper-making tobacco sheet raw materials

A technology of tobacco flakes and extraction liquid, which is applied in the field of preparation of tobacco thin slice raw material extraction liquid by papermaking method, can solve the problems of heavy miscellaneous gas, high requirements for production equipment, large investment, etc., and achieve energy saving and reduction of extraction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

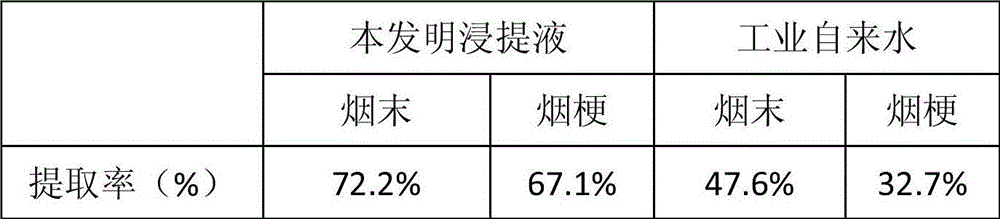

[0019] Propylene glycol is miscible with water, and the mass percentage of propylene glycol in the solution is respectively prepared as 0% to 25% (see Table 2 for details), and sodium bicarbonate (NaHCO 3 ), so that the concentration of sodium bicarbonate is 2%. The extracted liquid obtained and the raw material of the paper-making tobacco sheet were subjected to a single extraction under normal pressure at a mass ratio of 5:1, the extraction temperature was 40-80°C (see Table 2), and the extraction time was 30-90min (see Table 2) . Among them, propylene glycol and disodium bicarbonate are commercially available analytical reagents. The extraction results are shown in Table 2.

[0020] Table 2

[0021] Example

[0022] The results in Table 2 show that the addition of propylene glycol to the extract solution system at 3%-25% can significantly improve the extraction rate of raw materials, but when the concentration is higher than 20%, the extraction rate decreases s...

Embodiment 8-13

[0024] Be that the sodium bicarbonate of different amounts is added in the 10% propylene glycol aqueous solution in mass concentration, make the concentration of sodium bicarbonate be 0%-9% (specifically see Table 3), the extraction liquid that obtains is with papermaking method tobacco sheet raw material by mass ratio The ratio of 5:1 is carried out for a single leaching under normal pressure, the extraction temperature is 40-80°C (see Table 3), and the extraction time is 45min, 30-90min (see Table 3). Among them, propylene glycol and disodium bicarbonate are commercially available analytical reagents. The extraction results are shown in Table 3.

[0025] table 3

[0026] Example

[0027] The results in Table 3 show that the concentration of disodium bicarbonate solution in the range of 1%-5% can obviously improve the extraction rate of raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com