High-efficiency mercury-free energy-saving bulb

An energy-saving light bulb and high-efficiency technology, which is applied to the components of gas discharge lamps, etc., can solve the problems of mercury pollution and service life, and achieve the effects of prolonging service life, improving light efficiency and reducing mercury pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

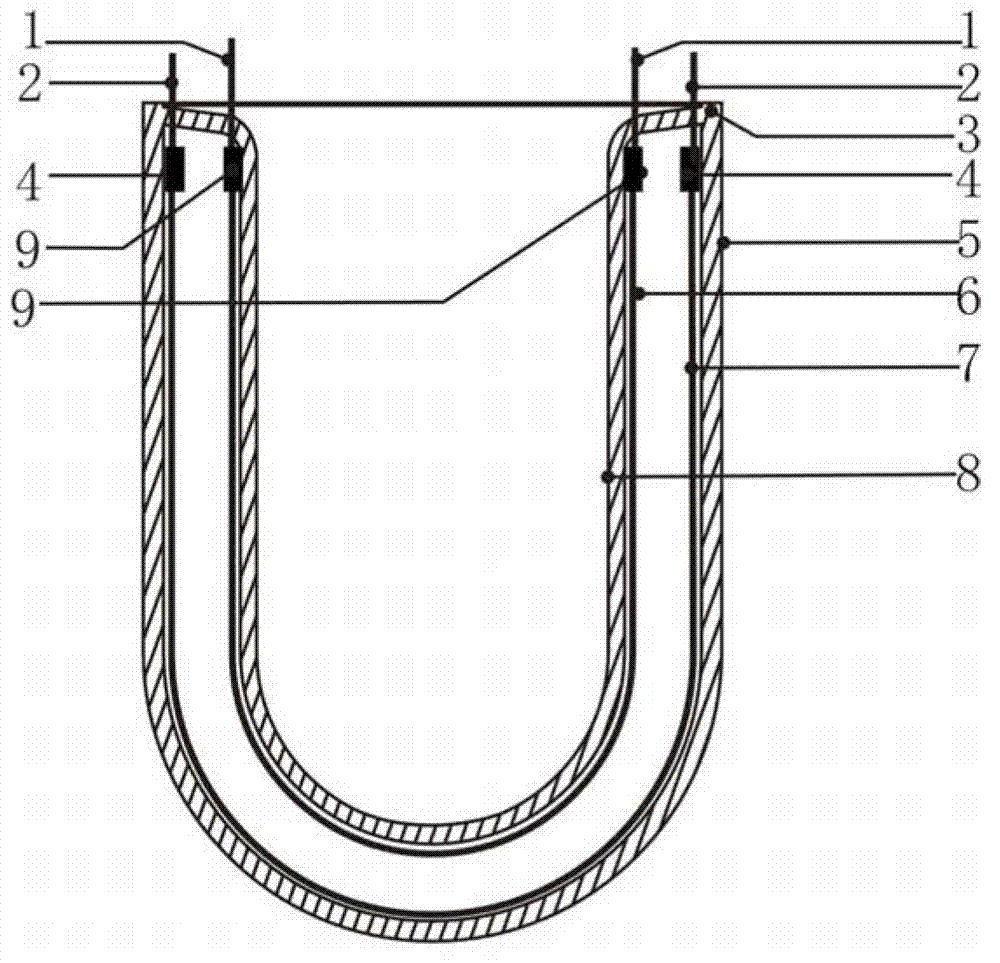

[0008] The inner bulb 8 is coated with the conductive coating and the phosphor coating 6 on the outer wall of the inner bulb, the inner wall of the outer bulb 5 is coated with the conductive coating and the phosphor coating 7 on the inner wall of the outer bulb, and the outer lamps are respectively bonded The bonding point 4 of the conductive material of the inner bulb and the bonding point 9 of the conductive material of the inner bulb are drawn out from the lead-out wire 1 of the bonding point of the conductive material of the inner bulb and the lead-out wire 2 of the bonding point of the conductive material of the outer bulb, and the inner The light bulb 8 and the outer light bulb 5 are sintered together to form a lamp body, the sintering point 3 of the inner light bulb and the outer light bulb is exhausted, the miscellaneous gas in the light body is discharged, and an inert gas such as neon gas is injected for sintering, and the lamp cap A is installed on the lamp tube and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com