Wall thickness linear model-based pipe mechanical property hydro-bugling testing method

A technology of hydraulic bulging and testing methods, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the problems of discontinuous experiments and difficult measurement of pipe wall thickness, so as to improve the testing efficiency and achieve reliable material performance results. Experimental Ease of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

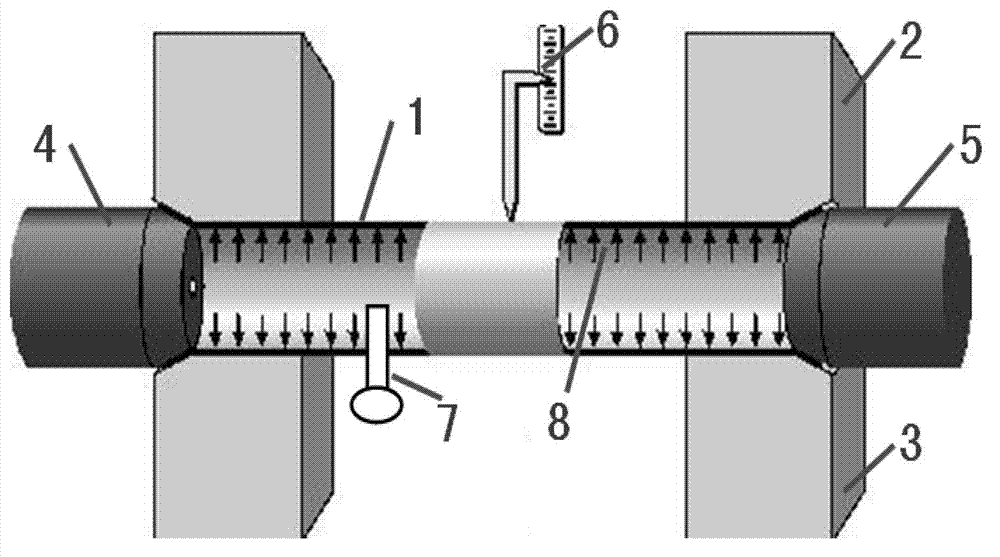

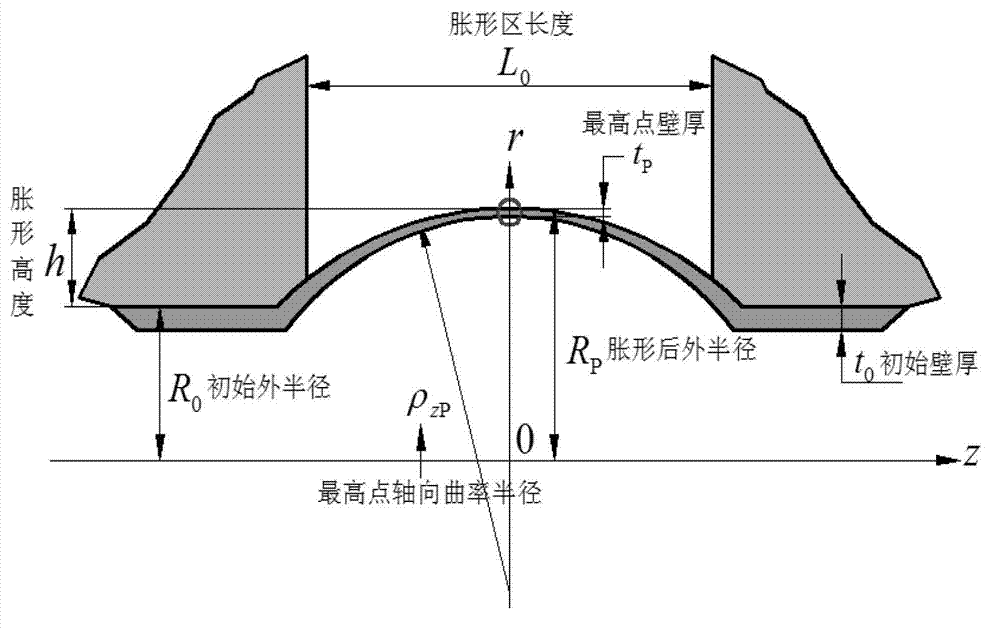

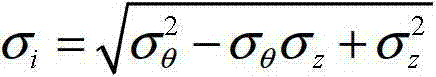

[0026] Specific implementation mode one: as Figure 1~2 As shown, the steps of the hydraulic bulging test method for the mechanical properties of pipes based on the wall thickness linear model in this embodiment are as follows:

[0027] Step 1. Measure the initial wall thickness t of the pipe to be tested 1 0 , the outer radius R of the pipe to be tested 1 0 and the length of the bulging zone L 0 ;

[0028] Step 2, placing the pipe material 1 to be tested between the upper mold 2 and the lower mold 3, and sealing the two ends of the pipe material 1 to be tested by the left sealing punch 4 and the right sealing punch 5;

[0029] Step 3: Fill the high-pressure liquid medium 8 into the pipe material 1 to be tested, and the pressure of the high-pressure liquid medium 8 is 15-300 MPa;

[0030] Step 4: Real-time record the pressure of the high-pressure liquid medium 8 and the bulging height h during the bulging process of the pipe 1 to be tested until the pipe 1 to be tested rup...

specific Embodiment approach 2

[0046] Specific implementation mode two: as figure 1 As shown, in step 3, the pressure of filling the high-pressure liquid medium 8 into the pipe 1 to be tested is 30-200 MPa. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Specific implementation mode three: as figure 1 As shown, in steps 1 and 5, an ultrasonic thickness gauge is used to measure the wall thickness of the pipe 1 to be tested. The range of the ultrasonic thickness gauge is 0-20 mm, and the measurement accuracy is 0.01 mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com