Vibration detecting device of non-contact type fluid component

A non-contact, vibration detection technology, used in measuring devices, instruments, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of control, inability to measure vibration, and the anti-vibration performance of vibration isolation measures cannot meet the requirements. Eliminate the cantilever beam structure, achieve precise control, and the effect of strong anti-vibration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and embodiments.

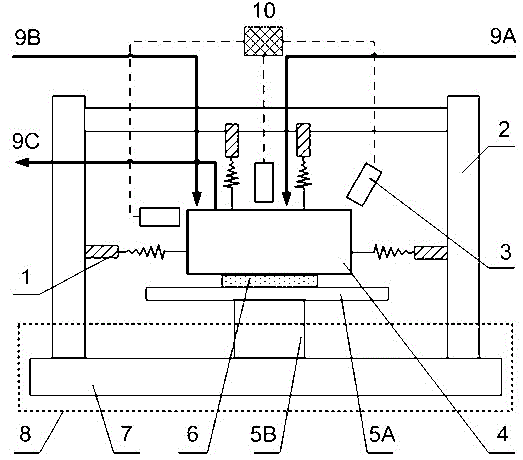

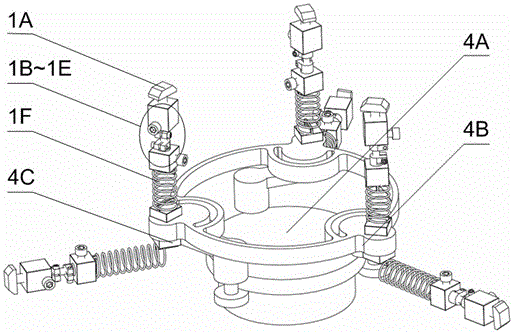

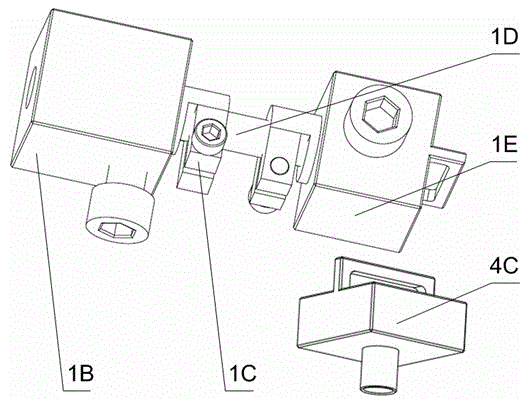

[0036] figure 1 The schematic diagram of the embodiment of the present invention is schematically shown. The maintenance of the gap flow field 6 requires the synergy of the liquid injection pipeline 9A, the recovery pipeline 9B and the gas sealing pipeline 9C; The attitude adjustment mechanism 1 and the manual precision lifting platform 5B can realize the control of the boundary of the slit flow field 6; the sensor measuring device 3 cooperates with the controller 10 to realize the measured fluid components and their clamps on the upper interface of the flow field of the slit flow field 6. The vibration detection of the holding mechanism 4; the vibration isolation platform 7 can effectively suppress the vibration from the ground; the motion platform 8 can create conditions for the vibration detection of the boundary surface of the gap flow field under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com