Cold and hot balancing ceramic valve

A ceramic valve, balanced technology, applied in the field of ceramic valves, can solve problems such as excessive manufacturing costs, matching use of ceramic valves and faucet product groups, and inconsistency with industrial economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

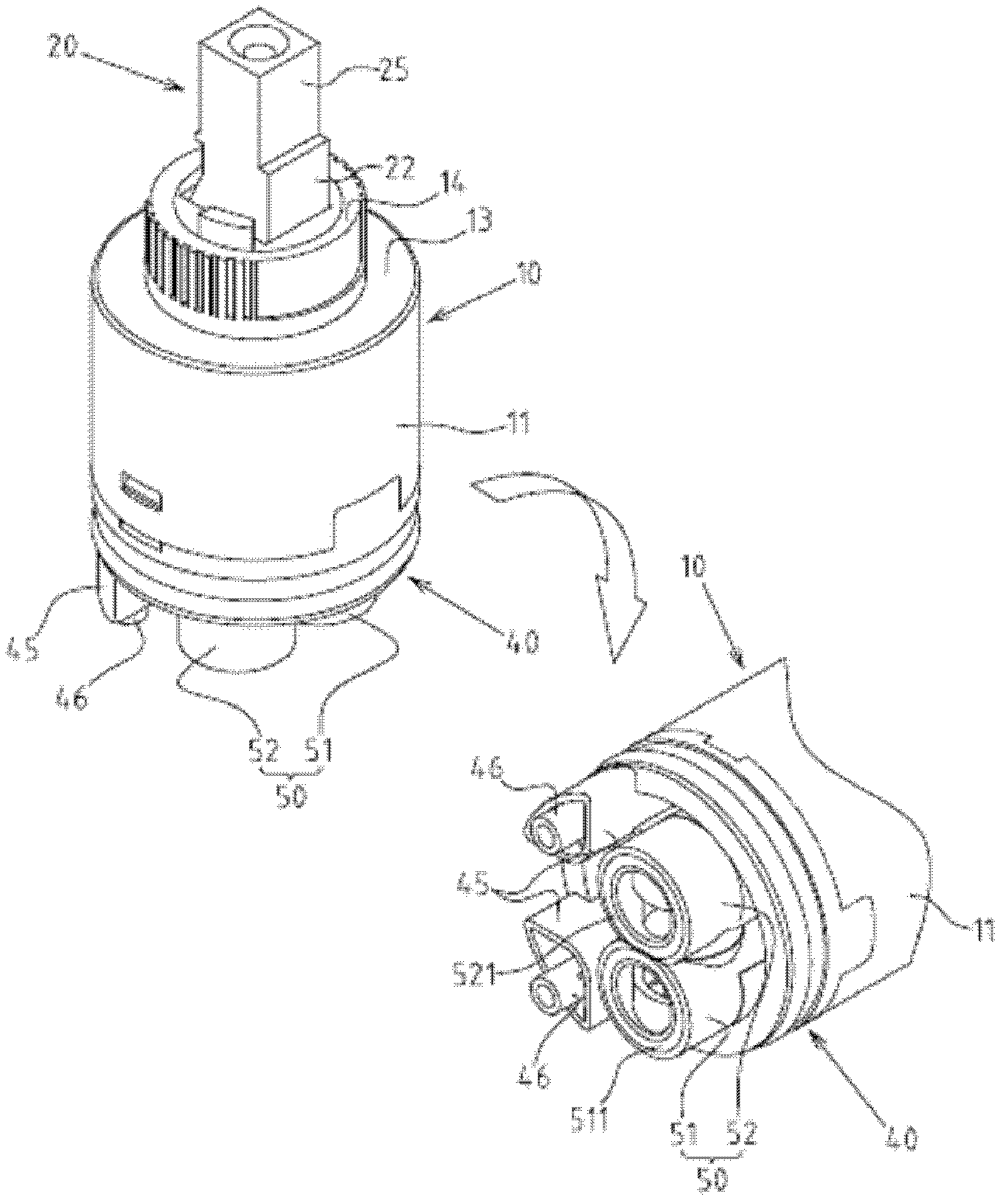

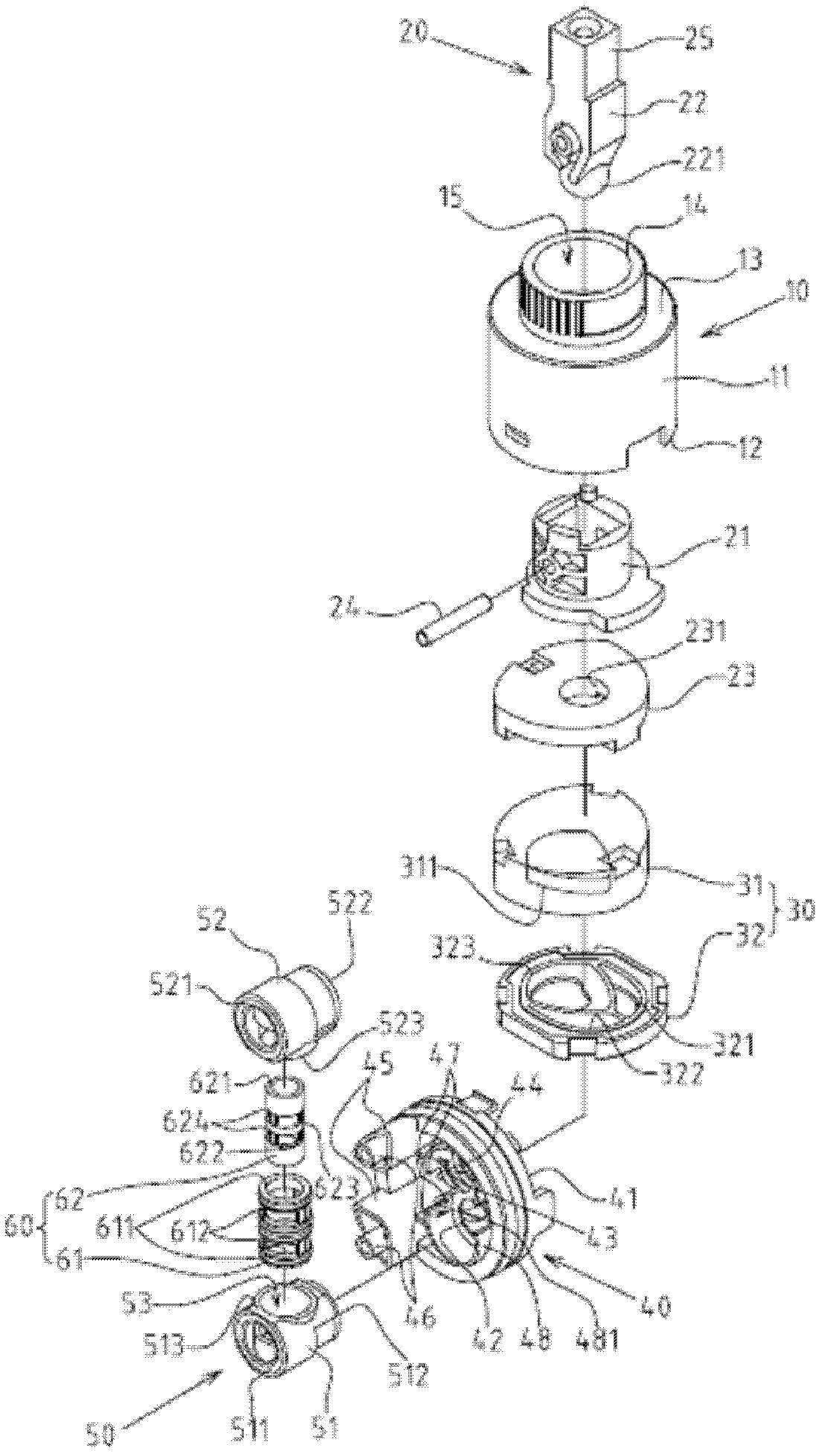

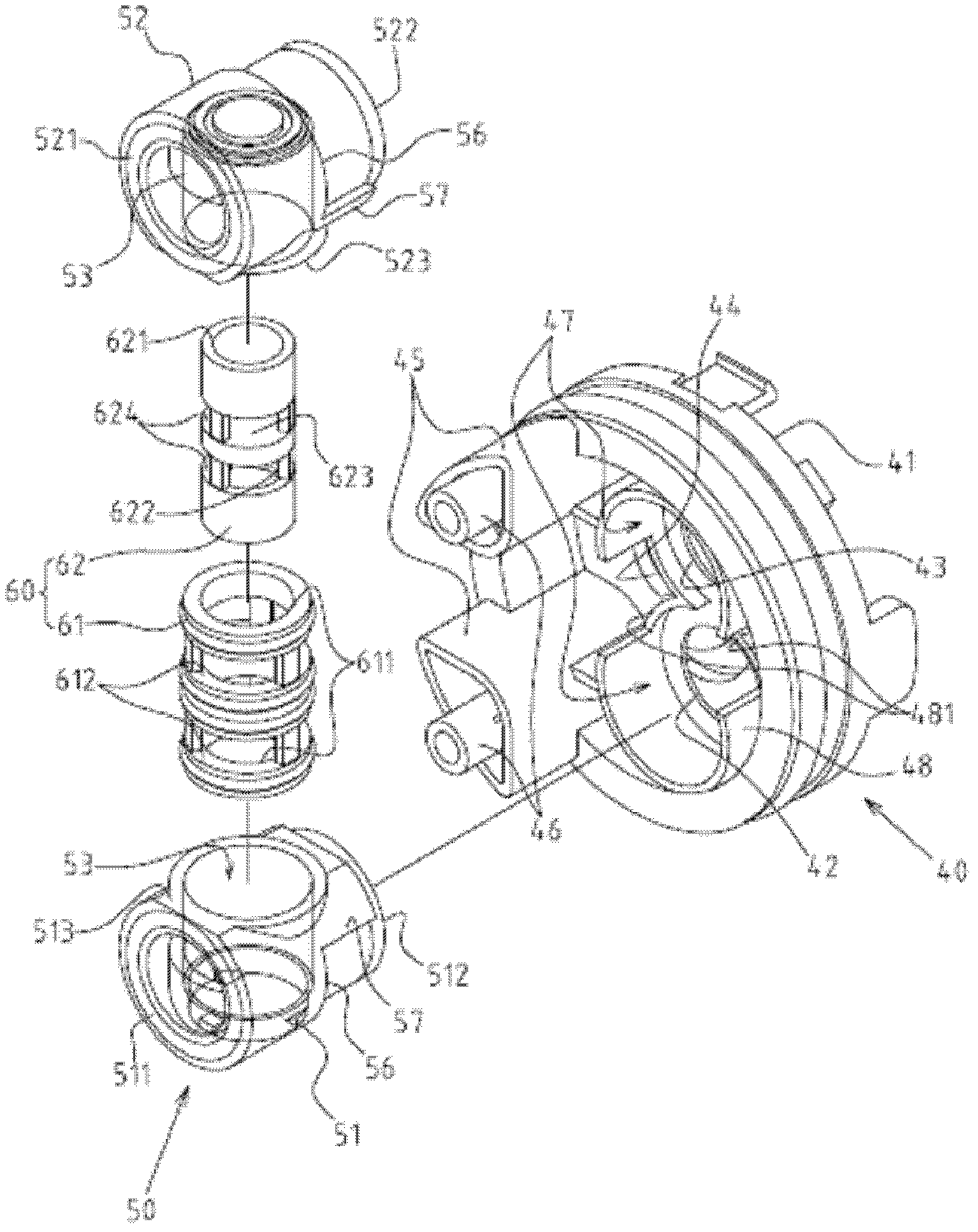

[0023] Such as figure 1 , 2 , 3, and 4 show the preferred embodiments of the cold and heat balanced ceramic valve of the present invention, but these embodiments are for illustration only, and are not limited by this structure in patent applications. The cold and heat balanced ceramic valve includes:

[0024] A standard valve housing 10 includes a peripheral wall 11, a bottom opening 12, a top end surface 13, a reduced diameter nozzle 14, and an internal storage space 15 are arranged on the top end surface 13, and wherein, the peripheral wall of the standard valve housing 10 11 The outer diameter size must be 40mm±1mm or 35mm±1mm in the standard specifications of ceramic valve products (as shown in D1 in Figure 4);

[0025] A water control member 20 includes a rotating seat 21, a lever 22 and a link plate 23, wherein the rotating seat 21 is rotatably assembled in the reduced-diameter nozzle 14 of the standard valve housing 10, and the lever 22 The middle section is pivotall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com