Bias gas-liquid two-phase jet-flow slotting permeability-increasing device and method

A gas-liquid, slotting technology, applied in safety devices, mining fluids, earth-moving drilling, etc., can solve the problems of complex equipment and operating procedures, harsh jet formation conditions, easy to cause water accumulation, etc., to achieve wide practicability, operation Easy and effective to reduce the coal breaking threshold pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

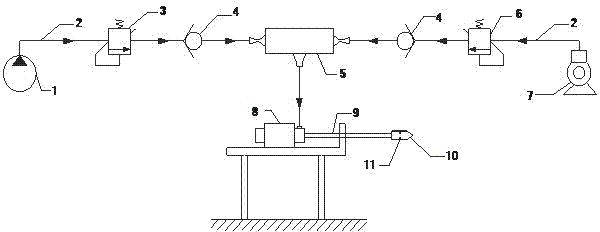

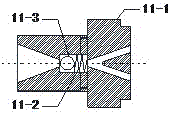

[0020] The biased gas-liquid two-phase jet slit anti-reflection device of the present invention mainly consists of a high-pressure water pump 1, a high-pressure resistant rubber hose 2, a pressure regulating valve 3, a one-way valve 4, a gas-liquid mixer 5, a pressure regulating valve 6, and a high-pressure air pump 7. Drilling rig 8, drill pipe 9, pressure control drill bit 10, and side nozzle 11. One side inlet of the gas-liquid mixer 5 is connected to the one-way valve 4, high-pressure water pressure regulating valve 3 and high-pressure Water pump 1, the inlet of the other side of the gas-liquid mixer 5 are connected to the check valve 4, the high-pressure gas pressure regulating valve 6 and the high-pressure gas pump 7 through the high-pressure resistant rubber hose 2 in turn; the outlet of the gas-liquid mixer 5 is connected to the drilling rig 8 The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com