Method for stripping rock layer of end slope

A technology of rock formations and end sides, which is applied in earth cube drilling, open-pit mining, special mining, etc. It can solve the problem of many steps and sections, reduce the stripping ratio and improve the efficiency of transportation operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

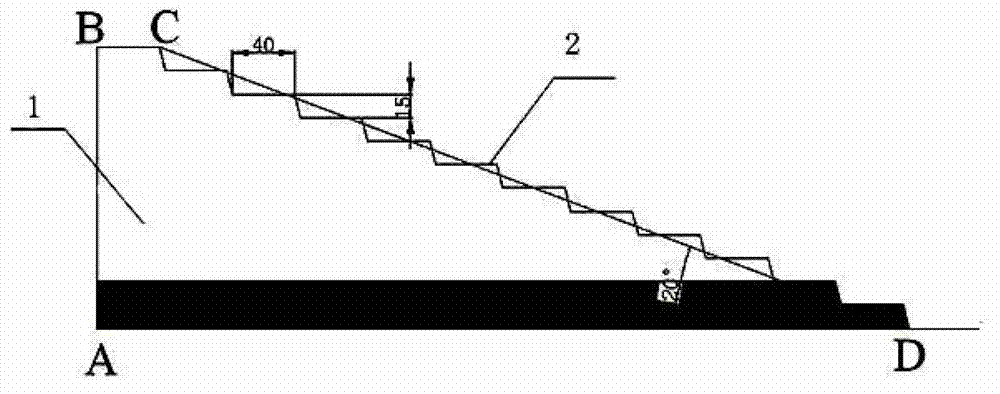

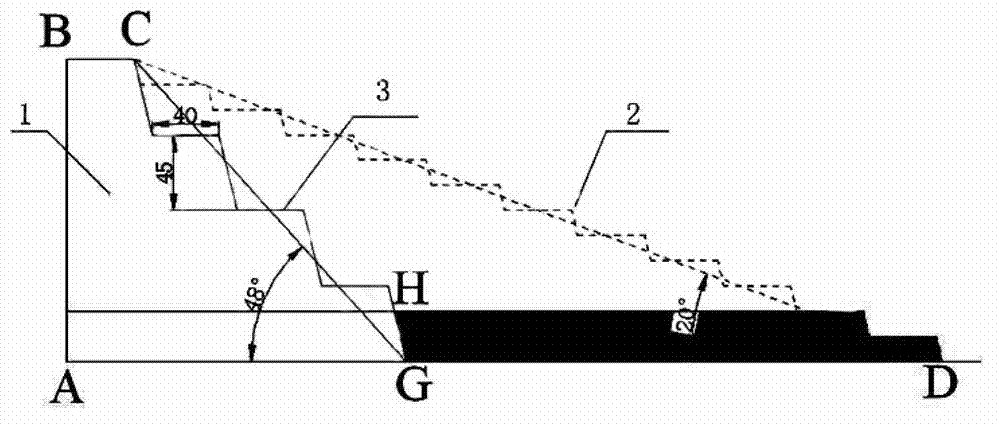

[0017] figure 1 is the structural schematic diagram of the original standard steps of the end gang, figure 2 Schematic diagram of the parallel step structure for implementing the end-side rock formation stripping method provided by the embodiment of the present invention. Embodiments of the present invention provide a method for stripping end rock formations, such as figure 1 with figure 2 As shown, the method includes:

[0018] Step a, from the highest point of the rock formation, more than three standard steps 2 are peeled off in sections to form a new step, that is, the back step 3 of the amalgamation.

[0019] The merging section refers to the operation process of compressing multiple steps into one step by horizontally advancing and deeply advancing multiple steps. A single-bucket truck can be used to merge standard steps 2. Taking three standard steps 2 each time as an example, first advance deeply from top to bottom, and then advance along the horizontal direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com