Hybrid Structural Rebar Connection Nodes

A technology for connecting nodes and hybrid structures, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of large amount of tasks, long time required, high difficulty in execution, etc., achieve a high level of industrialization, convenient construction, and welded surfaces smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

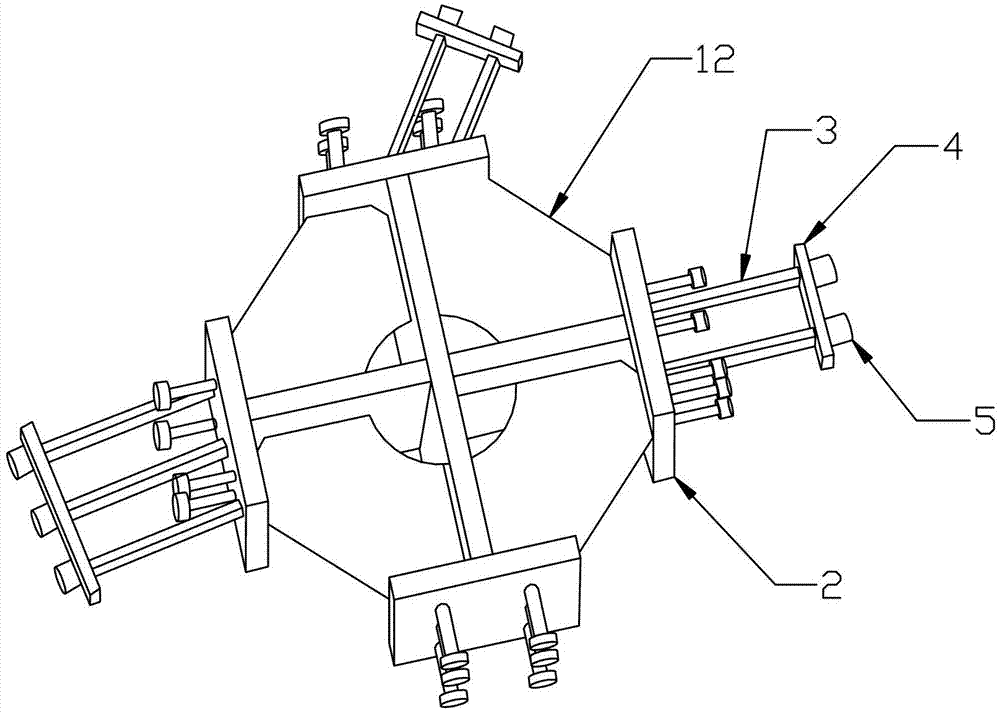

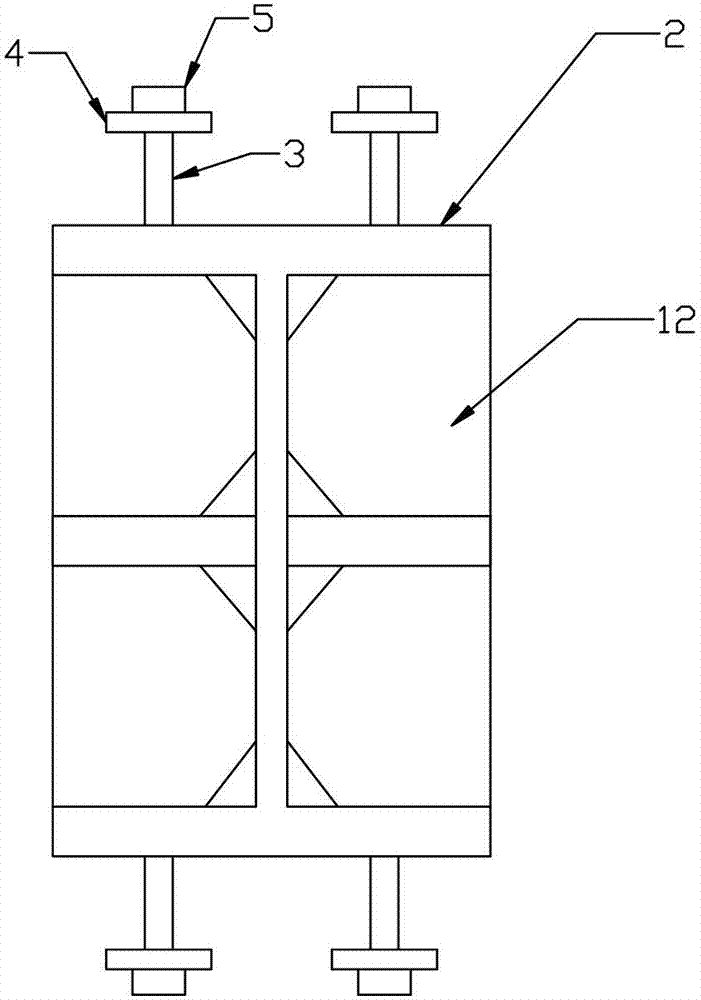

[0039] In high-rise buildings, the vertical force transmission part is composed of structural columns with different angles and thicknesses, such as circular tubular columns, cross steel column or king-shaped steel column, H-shaped steel column, etc. For example, during the construction process, when connecting reinforced concrete beams on a circular pipe column, it is necessary to pass through the steel bars of the concrete beam on the circular pipe column. Construction takes too long.

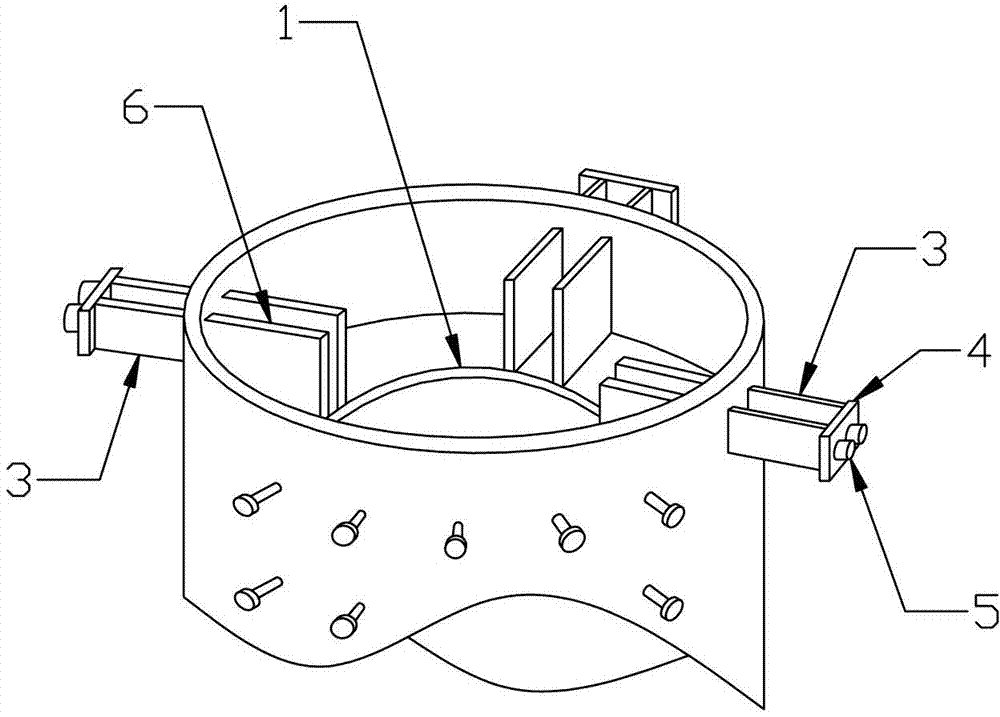

[0040] In order to solve the above problems, a hybrid structural steel bar connection node according to an embodiment of the present invention includes at least a structural column and a steel bar connector arranged on the outer surface of the structural column. Through the connector on the periphery of the structural column, it can be reasonably connected with the steel bar of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com