Construction method for constructing double-limb hollow high-pier mould side hydraulic jacking creeping formwork and double-limb hollow high-pier

A hollow and hydraulic technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of labor-intensive and time-consuming construction efficiency, small lifting height and low height of supporting embedded parts, and achieves low cost, structural safety and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

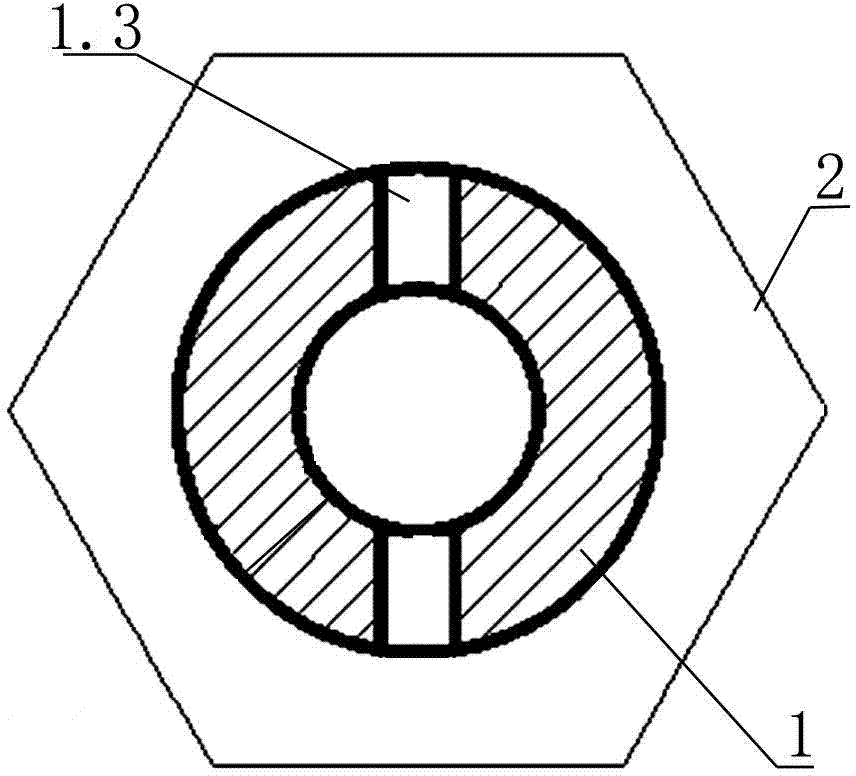

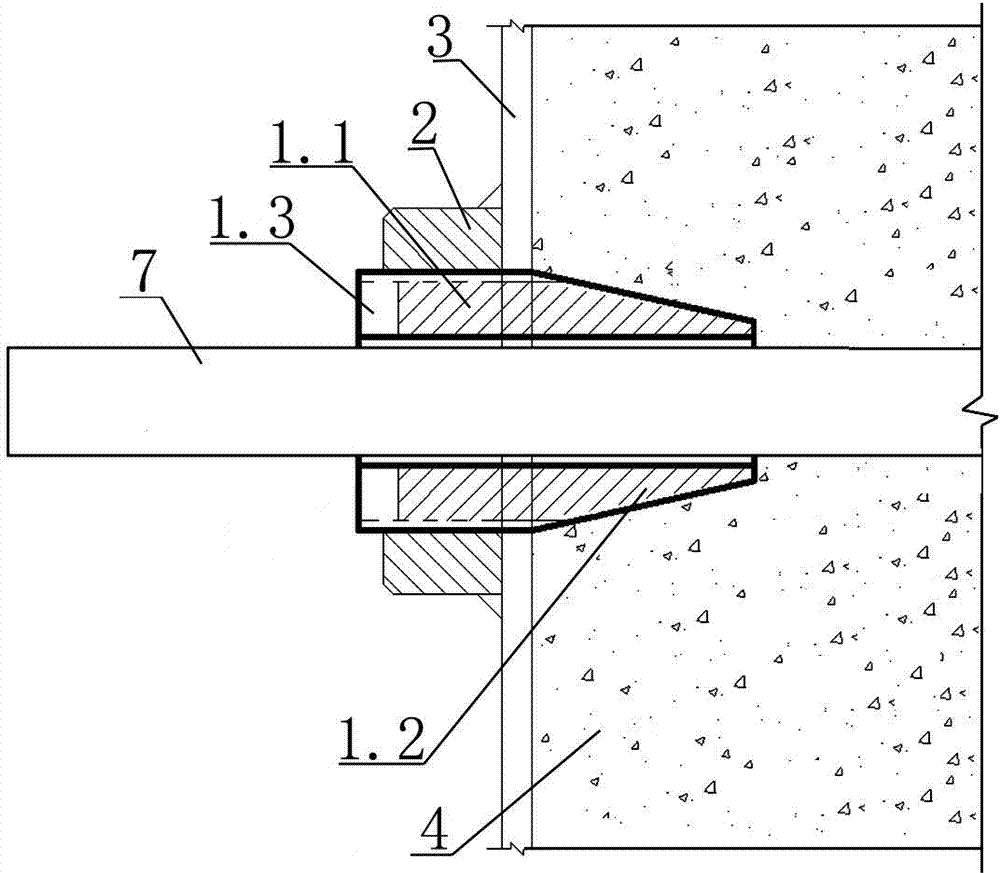

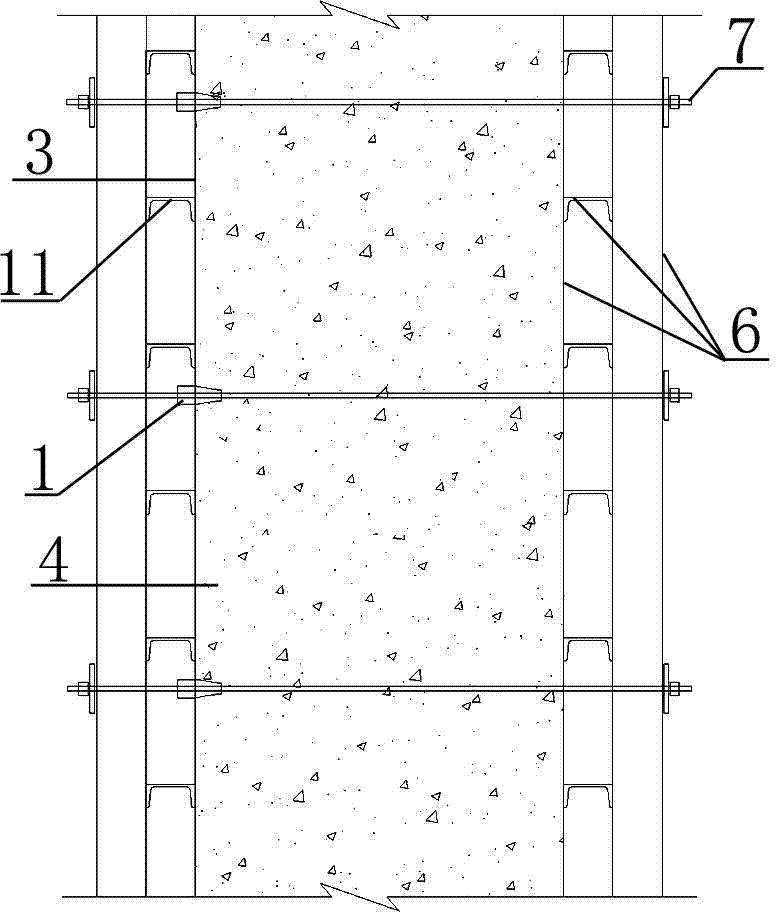

[0047] Examples see Figure 1 to Figure 10 As shown, a double-limbed hollow high pier mold side hydraulic jacking climbing form includes a joint truss construction platform 5, a formwork system and a hydraulic jacking device. The joint truss construction platform 5 is set up on the double-limbed concrete to be poured Outside the pier wall 4, the hydraulic jacking device is supported on the outside of the outer formwork, and at the same time, it is topped on the bottom surface of the joined truss construction platform 5 to control the lifting of the joined truss construction platform 5. The formwork system is composed of an inner formwork and an outer formwork. The inner template and the outer template are tied together by a tie rod 7, and there is a shear key 1 where the outer template and the tie rod 7 are inserted. The inner formwork 6 is composed of an inner mold panel and a grooved steel plate, and the grooved steel plate is evenly welded to the back of the inner mold plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com