Process for preparing drilling fluid based on control of dosage of viscosity reducer

A preparation process and viscosity reducer technology, which is applied in the field of drilling fluid preparation process based on controlling the amount of viscosity reducer, can solve the problem of poor temperature resistance, salt resistance and calcium resistance of the treatment agent, and the inability to control high-density water-based drilling Fluid rheology, weakening the rheology of high-density water-based drilling fluid system, etc., to achieve the effect of reducing preparation cost, easy operation and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] This embodiment relates to a drilling fluid preparation process based on controlling the amount of viscosity reducer, including the following steps:

[0035] (a) configure quantitative base slurry for subsequent use;

[0036] (b) Add tackifier PAC-HV under high-speed stirring until completely dissolved;

[0037] (c) Remove the PAC-HV slurry, pour it into the reaction container, then add the fluid loss reducer SMP-2 at one time according to the amount, and stir at a low speed to allow it to fully absorb to equilibrium to achieve the purpose of rubber protection;

[0038](d) Add KCl and NaCl at one time according to the amount, thicken first, then thicken until stable, stir at low speed to fully dissolve and function;

[0039] (e) Add deformable plugging agent FT-1 and rigid plugging agent CaCO at one time according to the amount 3 , stirring at low speed to allow it to fully disperse;

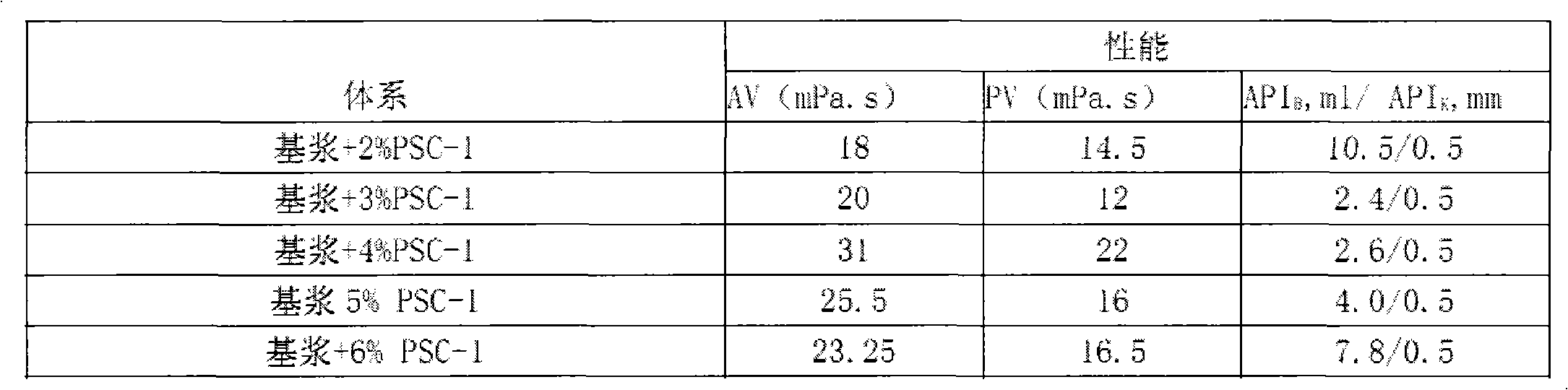

[0040] (f) Add the viscosity reducer PSC-1 at one time according to the amount, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com