Preparation method of environment-friendly organic composite salt snowmelt agent

A compound salt and deicing agent technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as polluted water bodies, soil compaction, and vegetation salt damage, achieving low corrosion, low freezing point, and reducing vegetation salt damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

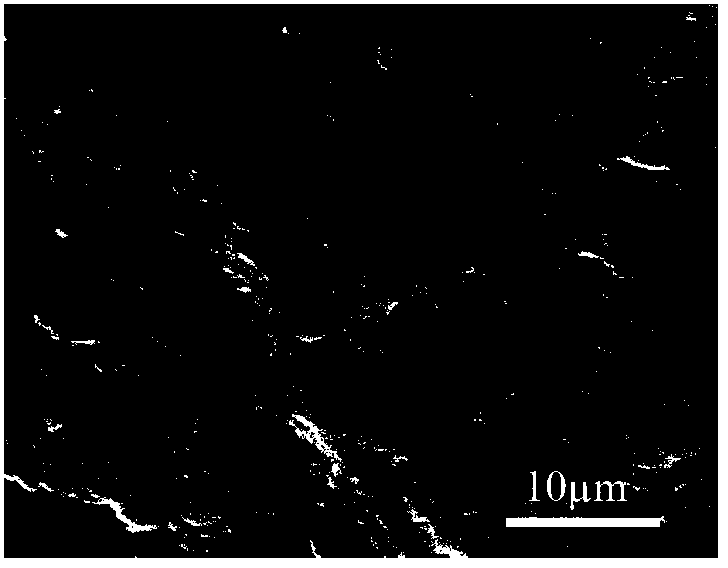

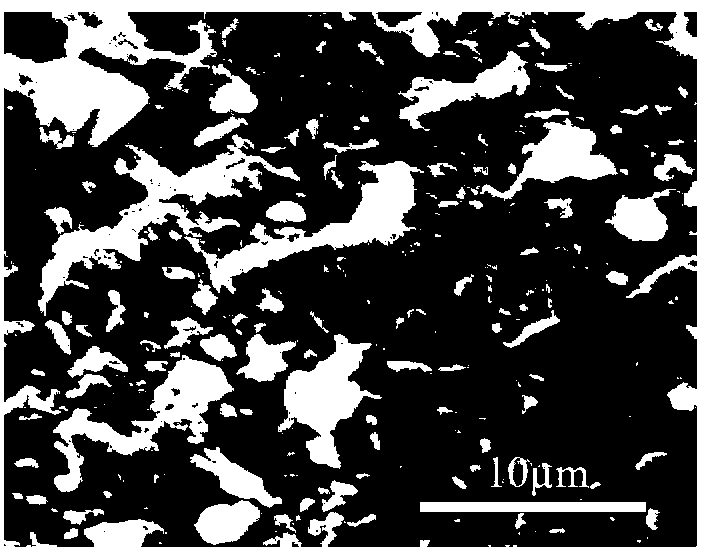

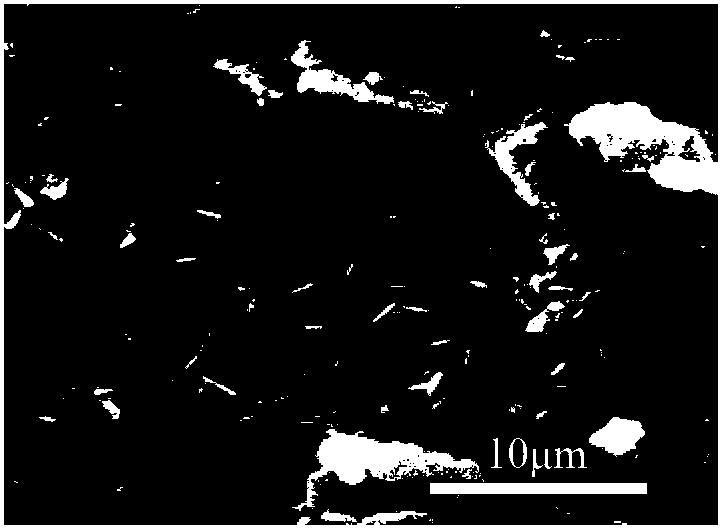

Image

Examples

Embodiment 1

[0025] Taking 100g humic acid as raw material, the method for preparing environment-friendly organic compound salt deicing agent is realized by the following steps:

[0026] (1) At room temperature, weigh 70g of sodium chloride to make a saturated solution, add 100g of humic acid to it, make the mass ratio of humic acid and sodium chloride 1:0.7, stir well, and reflux at 70°C for 2h to obtain The association solution of humic acid and sodium chloride.

[0027] (2) Take the association solution in step (1), add sodium carbonate to adjust the pH of the solution to 7, place it in an oven to heat and dry at 100°C, and obtain an organic compound salt deicing agent.

Embodiment 2

[0029] Taking 100g humic acid as raw material, the method for preparing environment-friendly organic compound salt deicing agent is realized by the following steps:

[0030] (1) At room temperature, weigh 60g of sodium chloride to prepare a saturated solution, add 100g of humic acid to it, make the mass ratio of humic acid and sodium chloride 1:0.6, stir well, and reflux at 70°C for 2h to obtain The association solution of humic acid and sodium chloride.

[0031] (2) Take the association solution in step (1), add sodium carbonate to adjust the pH of the solution to 7, place it in an oven to heat and dry at 100°C, and obtain an organic compound salt deicing agent.

Embodiment 3

[0033] Taking 100g humic acid as raw material, the method for preparing environment-friendly organic compound salt deicing agent is realized by the following steps:

[0034] (1) At room temperature, weigh 80g of sodium chloride to prepare a saturated solution, add 100g of humic acid to it, make the mass ratio of humic acid and sodium chloride 1:0.8, stir well, and reflux at 70°C for 2h to obtain The association solution of humic acid and sodium chloride.

[0035] (2) Take the association solution in step (1), add sodium carbonate to adjust the pH of the solution to 7, place it in an oven to heat and dry at 100°C, and obtain an organic compound salt deicing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com